- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Voltage:

-

380V/220V/As required

-

Product name:

-

Small Scale Cassava Garri Processing Machine

-

Material:

-

Stainless steel

-

Application:

-

Vegetable, Cassava, yam, konjac, sweet potato, onion, chilli, ginger

-

Final product:

-

Dried cassava chips

-

Advantage:

-

Industrial Automatic, High Effieciency

-

Processing Types:

-

Food Process Equipment

-

Machine:

-

cassava washing peeling machine, cassava dryer, cassava cutter

-

Warranty:

-

One year

-

Certificate:

-

CE

-

Type:

-

Cassava chips processing line

Quick Details

-

Machinery Capacity:

-

200-300kg/h

-

Brand Name:

-

Baixin

-

Weight:

-

5000 KG

-

Place of Origin:

-

China

-

Voltage:

-

380V/220V/As required

-

Product name:

-

Small Scale Cassava Garri Processing Machine

-

Material:

-

Stainless steel

-

Application:

-

Vegetable, Cassava, yam, konjac, sweet potato, onion, chilli, ginger

-

Final product:

-

Dried cassava chips

-

Advantage:

-

Industrial Automatic, High Effieciency

-

Processing Types:

-

Food Process Equipment

-

Machine:

-

cassava washing peeling machine, cassava dryer, cassava cutter

-

Warranty:

-

One year

-

Certificate:

-

CE

-

Type:

-

Cassava chips processing line

Products Description

Small Scale Cassava Processing Machine

Cassava washing

peeling washing and cutting crushing

production line has continuous automatic production, fast processing speed, high output and good quality. Including cassava washing and peeling machine, cassava slicer, cassava dryer, and other equipment, which can be used for deep processing of cassava dehydrated chips, cassava flour, etc. The production line adopts advanced technology, and the output of cassava is high, Price direct. This is the best choice for cassava processing enterprises, and it is also the most ideal equipment for cassava processing at present.

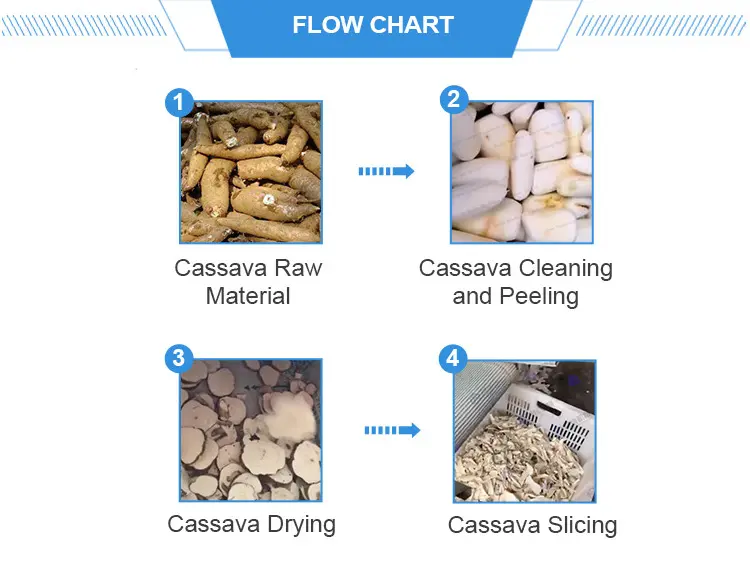

Working process of cassava processing line:

cassava washing and peeling-slicing-drying.

A complete cassava processing plant mainly includes:

cassava washing and peeling machine, cassava slicer, cassava chips dryer, etc., each equipment interacts, connected by a hoist.

|

200-300kg/h small scale cassava processing machine production line

|

|

|

|

|

||||

|

No.

|

Machine Name

|

Power

|

Size(mm)

|

Capacity

|

||||

|

1

|

Cassava Washing and Peeling Machine

|

0.75kw

|

2120*840*900

|

500kg/h

|

||||

|

2

|

Cassava Slicer Machine

|

1.5kw

|

900*850*900

|

500kg/h

|

||||

|

3

|

Cassava Dryer

|

3kw

|

2100*930*2100

|

200-300kg/h

|

||||

|

Cassava processing machine can be equipped according to the user's requirement and the production demands.

|

|

|

|

|

||||

|

1000kg/h automatic cassava processing machine production line

|

|

|

|

|

||||

|

No.

|

Machine Name

|

Power

|

Size(mm)

|

Capacity

|

||||

|

1

|

Cassava Washing and Peeling Machine

|

3.75kw

|

3200*1100*1350

|

1000kg/h

|

||||

|

2

|

Cassava Slicer Machine

|

1.5kw

|

900*850*900

|

1000kg/h

|

||||

|

3

|

Cassava Dryer

|

33.12kw

|

12000*2000*2500

|

1000kg/h

|

||||

|

Cassava processing machine can be equipped according to the user's requirement and the production demands.

|

|

|

|

|

||||

Cassava washing and peeling machine:

The cassava is placed in the machine, and the brush sweeps and turns the ingredients for cleaning and removing the skin. Then, it enters the spray water section to wash away the dirt that has been brushed on the raw materials until it is washed. The specially designed screw feeding structure is used to realize fully automatic operation.

Cassava cutting machine:

Cut the cassava into even slices. The thickness of cassava slices is uniform, and the slice thickness can be adjusted as needed. which has a good effect on the later drying process. This uniform cassava slice can keep the time and effect of the drying process under the same conditions, so the overall drying effect will also be very high, which meets the processing standards of large-scale enterprises in the drying of cassava slices.

Cassava dryer:

It can effectively remove the surface moisture of cassava chips and shorten the drying time of cassava.

Advantages

Advantages of cassava processing line

1: Can be customized.

Configure different production lines according to customer output requirements.

The cassava production line is fully automatic and semi-automatic, and customers can choose according to their own needs.

2: Easy to operate.

The cassava production line is easy to install and can be used after connecting to the power supply. It is reliable to use and easy to disassemble.

3: Cassava is of high quality.

The dryer adopts medium and low temperature drying. After drying, the original color and nutrients of cassava can be completely retained. The equipment is made of stainless steel, in line with food machinery standards.

4:Flexible heat source selection of dryer.

Coal, wood chips, natural gas, diesel, propane, electricity etc.

5: Wide range of applications.

Most of the machines in the line are not only suitable for cassava, but also for other fruits and vegetables.

About Us

The world's leading manufacturer of cassava processing machinery Customize cassava production line for special purpose to meet your unique demand.

1. we have our own factory, our own workshop, not rent.

2. we have qualified technical workers, ensure the food machine well-made.

3. we have our own technical team and installation department, we can guarantee overseas services.

4. we have rich stock for check,also can delivery machine as soon as possible.

Baixin has 15 years of experience in customized solutions for potato processing lines. Since its establishment, Baixin has been committed to providing the best potato processing solutions to users around the world. We provide one-stop turn-key project and make different solutions for different demands.

The main products are vegetables & fruits processing line, such as fruit and vegetable washing machine, peeling machines, slicers, dryers, mills, packaging machines, so on.

Packing & Delivery

FAQ

1: Which size of machine is suitable for me?

We offer three different size of

Cassava Processing Line

Equipment: Output capacity available 100kg/h, 200kg/h-300kg/h, 500kg/h, 1000kg/h, etc.

Based on your production situation, you can choose the suitable one.

2: What is the heat source for the machines?

There are several different Heating method for the machines : Electric heating, Gas heating or Electricity heating and gas heating both in one. You can choose the right one for your need.

3: What special service can be provided?

We can design floor plan of complete line as you need depending on your area' s size.

Hot Searches