- Product Details

- {{item.text}}

Quick Details

-

Device size:

-

12700MM*1980MM*2000MM

-

Working size:

-

3000mm*1250mm*50mm

-

Working speed:

-

4min/piece

-

Max processing height:

-

100mm

-

Suction pressure:

-

23.2kw

-

Average power:

-

10kw

-

Vacuum pump:

-

Chinese vacuum pump

-

Control system:

-

PLC

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Keyword:

-

vacuum membrane press machine

-

Table size:

-

3000*1250*50mm

-

Device size:

-

12700MM*1980MM*2000MM

-

Working size:

-

3000mm*1250mm*50mm

-

Working speed:

-

4min/piece

-

Max processing height:

-

100mm

-

Suction pressure:

-

23.2kw

-

Average power:

-

10kw

-

Vacuum pump:

-

Chinese vacuum pump

-

Control system:

-

PLC

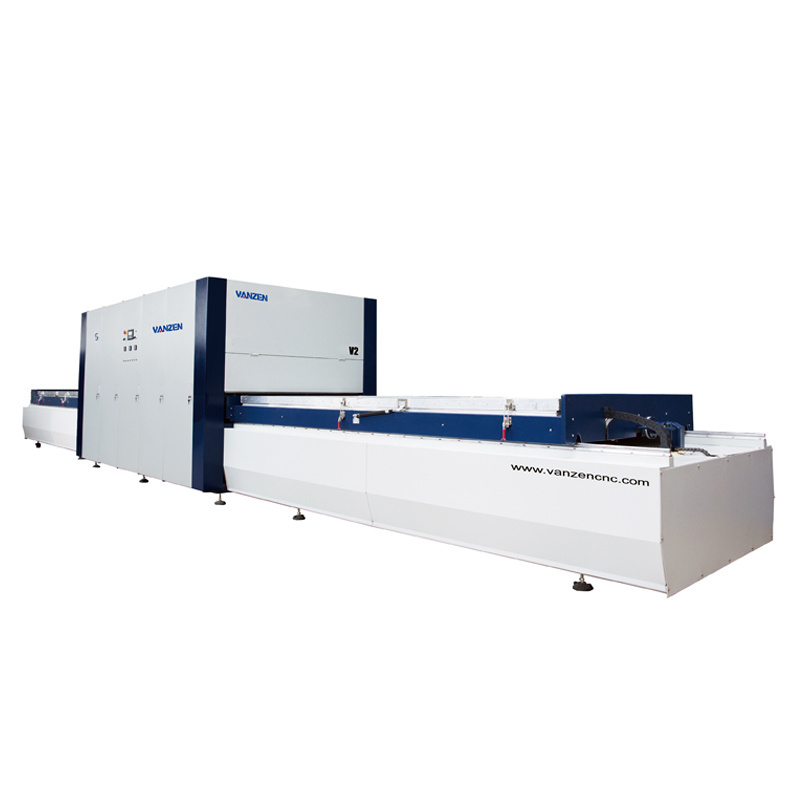

Woodworking Machinery automatic pvc foil vacuum membrane press machine

| Specification parametersr | V2 |

| Device dimension | 11000mm*1960mm*2000mm |

| Table size | 3000mm*3000mm*50mm |

| Device size | 12700MM*1980MM*2000MM |

| Working size | 3000mm*1250mm*50mm |

| Working speed | 4min/piece |

| Max processing height | 100mm |

| Machine wight | 4000kg |

| Suction pressure | 23.2kw |

| The total power | 42.7kw |

| Average power | 10kw |

| Vacuum pump | Chinese vacuum pump |

| Control system | PLC |

| Temperature control | themocouple |

| Heating system | Aluminum plate,stainless heating tube |

The whole electrical parts are all imported original,low-voltage electrical parts are Schneider brand, and its low-voltage miniature circuit breakers are Schneider original products. AC contactor’s cost is fifteen times higher than domestic parts but its life is three million times.

The controller’s PLC is DELTA brand, few wiring and easy controlling, so fault rate is much lower.

Vacuum pump supplier is the OEM of European partners, its main technical parameter are already beyond Germany products. Easy maintenance and high vacuum, air flues connecting working table are chrome-plated seamless steel tube, stable running and noiseless.

The working table is connected by bolts, easy dismounting and cleaning. PVC pressing frame adopts 6061T6 aluminum alloy extrusions and it is not hot after long time working. Table running adopts chain of transmission and Frequency control, with low fault rate, smoothly running keep work-piece no shifting.

2.High production efficiency

Aluminum alloy heating fast, and three meters long working table, 150 square meters PVC paint-free door of cabinet could be finished daily.

3.Saving energy

Thicker heating and thermal insulation structure for main heating oven, it will save electricity 30% than before.

1.By phone, email,skype around the clock

2.Engineer available to service machinery overseas

3.We could the video and pictures to teach our client how to use the machine

After sales services

Normal machine is properly adjusted before dispatch

You will be able to use the machine very soon

You will be able to get free training adivce towards our machine in our factory

You will get free suggestion consulting technical support and service by email tel and lifetime technical support.

Our vacuum membrane press machine dispaly

Our vacuum membrane press machine packing &shipping

Delivery: Within 15 days after the deposit

Packing: Wooden case or as your requirement

Payment: 15-30days after down payment or LC

Our vacuum membrane press machine sample