- Product Details

- {{item.text}}

Quick Details

-

MF:

-

ZrO2

-

EINECS No.:

-

215-227-2

-

Place of Origin:

-

Hebei, China

-

Appearance:

-

White Powder, powder

-

Application:

-

industry

-

Brand Name:

-

yingye

-

Model Number:

-

1

-

Product name:

-

Zirconium dioxide

-

Color:

-

White

-

FOB:

-

TIANJIN,XINGANG PORT ,CHINA

-

Packing:

-

25kg/bag, 50kg/bag

-

Sample:

-

Free(500g)

-

MOQ:

-

10MT

-

Usage:

-

industry

Quick Details

-

CAS No.:

-

1314-23-4

-

Purity:

-

99, 99min,

-

Other Names:

-

Zirconic anhydride

-

MF:

-

ZrO2

-

EINECS No.:

-

215-227-2

-

Place of Origin:

-

Hebei, China

-

Appearance:

-

White Powder, powder

-

Application:

-

industry

-

Brand Name:

-

yingye

-

Model Number:

-

1

-

Product name:

-

Zirconium dioxide

-

Color:

-

White

-

FOB:

-

TIANJIN,XINGANG PORT ,CHINA

-

Packing:

-

25kg/bag, 50kg/bag

-

Sample:

-

Free(500g)

-

MOQ:

-

10MT

-

Usage:

-

industry

Product introduction

Zirconium dioxide

Zirconium dioxide, chemical formula ZrO2, is the main oxide of zirconium, usually white odorless, tasteless crystals, insoluble in water, hydrochloric acid and dilute sulfuric acid. Its chemical properties are not active, and it has the properties of high melting point, high resistivity, high refractive index and low thermal expansion coefficient, which makes it an important high-temperature resistant material, ceramic insulation material and ceramic sunshade, and is also the main raw material for artificial drilling.

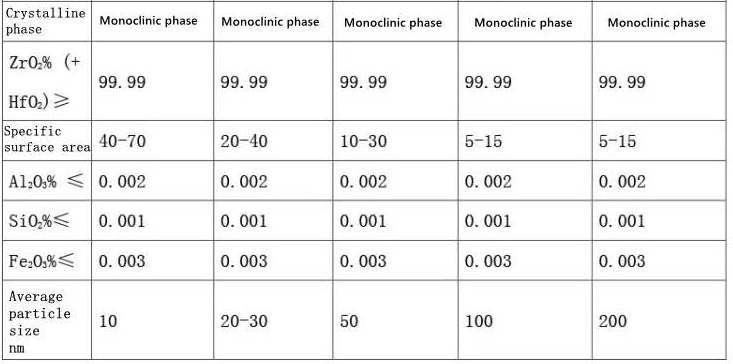

Specification

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product application

Raw materials of metal zirconium and its compounds

It is used for making metal zirconium and zirconium compounds, making refractory bricks and crucible, high-frequency ceramics, grinding materials, ceramic pigments and zirconates, etc. It is mainly used for piezoelectric ceramic products, daily ceramics, refractory materials and precious metal melting zirconium bricks, zirconium tubes, crucbles, etc. It is also used in the production of steel and non-ferrous metals, optical glass and zirconia fibers. It is also used in ceramic pigments, electrostatic coatings and baking paints. Used in epoxy resins to increase corrosion of heat-resistant saline.

refractory

Zirconia fiber is a kind of polycrystalline refractory fiber material. Due to the high melting point, non-oxidation and other high temperature characteristics of ZrO2 itself, ZrO2 fiber has a higher service temperature than alumina fiber, mullite fiber, aluminum silicate fiber and other refractory fiber varieties. Zirconia fiber in the ultra-high temperature oxidation atmosphere above 1500 ℃ for a long time, the highest use temperature of up to 2200 ℃, even to 2500 ℃ can still maintain a complete fiber shape, and high temperature chemical stability, corrosion resistance, oxidation resistance, thermal shock resistance, non-volatile, pollution-free, is currently the world's top a refractory fiber material. The acid and alkali corrosion resistance of ZrO2 is much stronger than that of SiO2 and Al2O3. Insoluble in water, soluble in sulfuric acid and hydrofluoric acid; Slightly soluble in hydrochloric acid and nitric acid. It can be fused with alkali to form zirconate.

Gas turbine

The application of plasma spraying zirconia thermal barrier coating on aviation and industrial gas turbines has made great progress, and has been used in turbine parts of gas turbines to a certain extent. Since this coating can reduce the temperature of gas-cooled high-temperature components by 50 to 200 ° C, it can significantly improve the durability of high-temperature components, or allow to increase the gas temperature or reduce the amount of cooling gas required to keep the temperature of high-temperature components unchanged, thereby improving the efficiency of the engine. [3]

Ceramic material

Because of its large refractive index, high melting point and strong corrosion resistance, zirconia is used as raw material in kiln industry. Piezoelectric ceramic products include filter, loudspeaker ultrasonic underwater acoustic detector and so on. There are also daily ceramics (industrial ceramic glaze), zirconium bricks and zirconium tubes for precious metal smelting. Nanoscale zirconia can also be used as a substrate for polishes, abrasive particles, piezoelectric ceramics, precision ceramics, ceramic glazes and high-temperature pigments.

other

In addition, zirconia can be used in the manufacture of white heat gas lampshade, enamel, white glass, refractory crucible, etc. X-ray photography. Abrasive material. Together with yttrium, it is used to manufacture light source lamps in infrared spectrometers, thick film circuit capacitive materials, and piezoelectric crystal transducers.

Hot Searches