- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4800x2100x5250 mm

-

Weight:

-

37000 KG

-

Place of Origin:

-

Mexico

-

Voltage:

-

Customized

-

Product Type:

-

Automatic Wood Pallet Machine

-

Machine Type:

-

Wood Pallet Machine

-

Core Components:

-

Motor, PLC, Pressure vessel

-

Capacity:

-

324 pcs/24h

-

Mold numbe:

-

one upper mold and one lower mold

-

After sale service:

-

24 hours online service

-

Raw material:

-

Waste wood, dead branches, scraps, waste boards

-

Application:

-

Logistics, transportation, warehousing, etc.

-

Power Source:

-

Hydraulic

-

Color:

-

Costomized

-

Name:

-

hydraulic pallet press machine

Quick Details

-

Machinery Capacity:

-

432 pcs/24h

-

Brand Name:

-

PalletMach

-

Year:

-

2yers

-

Dimension(L*W*H):

-

4800x2100x5250 mm

-

Weight:

-

37000 KG

-

Place of Origin:

-

Mexico

-

Voltage:

-

Customized

-

Product Type:

-

Automatic Wood Pallet Machine

-

Machine Type:

-

Wood Pallet Machine

-

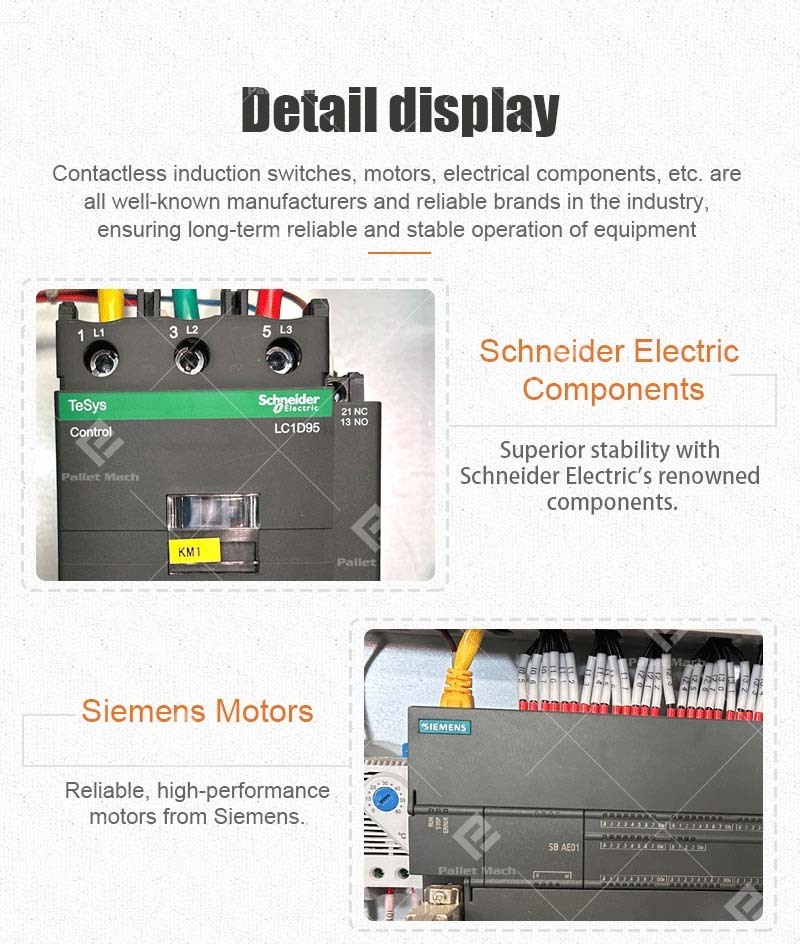

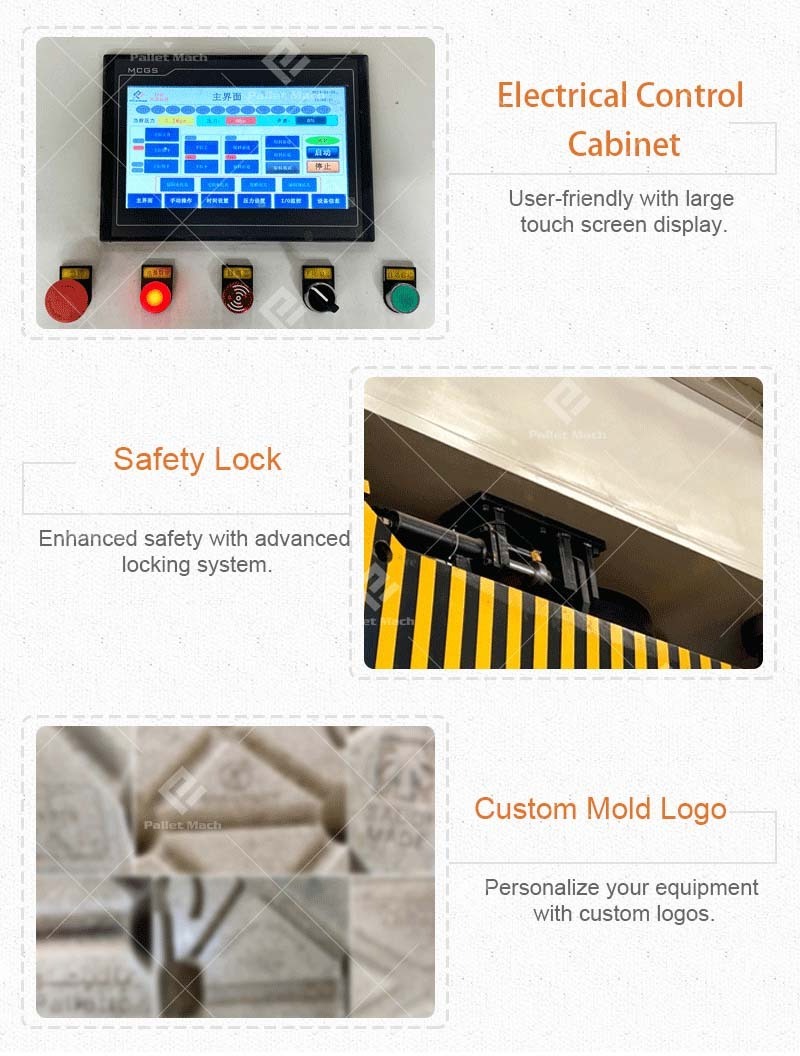

Core Components:

-

Motor, PLC, Pressure vessel

-

Capacity:

-

324 pcs/24h

-

Mold numbe:

-

one upper mold and one lower mold

-

After sale service:

-

24 hours online service

-

Raw material:

-

Waste wood, dead branches, scraps, waste boards

-

Application:

-

Logistics, transportation, warehousing, etc.

-

Power Source:

-

Hydraulic

-

Color:

-

Costomized

-

Name:

-

hydraulic pallet press machine

Products Description

PalletMach 1200*1000mm Compressed Wooden Pallet Moulding Press Machine Hydraulic Sawdust Wood Pallet Compressed Machine

Compressed Pallet Making Machine

The compressed pallet machine mainly uses waste wood, sawdust, shavings and straw as raw materials to produce molded pallets. These raw materials are very common in life and easy to get. The compressed wood pallet machine is very simple in structure and easy to operate, and can produce various types of wood chips molded pallets.The mold is the core part of the machine. By customizing different molds, hydraulic pallet machine can produce molded pallets of various specifications. Customers can choose suitable molded wood pallet machine according to their needs.

The wood pallet machine mainly uses wood chips, shavings, logs, planks, branches, waste pallets, crop waste, cotton straw, coconut fiber, etc as raw materials to produce molded pallets. The three-beam and four-column mechanism is adopted to completely solve the problems of inaccurate mold clamping and pallet burrs.

Details Images

Compared with manual pallet equipment, automatic molded pallet production line has the following advantages:

--Improve production efficiency: The automated production line can quickly and accurately complete the pallet manufacturing, and the production efficiency is higher than that of manual equipment. It can work continuously for 24hours without affecting production efficiency due to fatigue.

--Reduce production cost: The one-time investment cost of the automated production line is relatively high, but as it is put into production, the production cost will gradually decrease. In comparison, making pallets manually requires hiring a large number of workers. In addition to wage costs, you also need to pay for related benefits, insurance and other expenses.

--Improve production quality: The automated production line can accurately control each process to ensure the quality and stability of the pallet.

--Reduced labor: Automated production lines can reduce the need for manual labor. The process of pallet manufacturing requires a lot of repetitive labor, which is done by automated equipment.

--Improve safety: Automated production lines can avoid accidental injuries to workers due to improper operation, fatigue and other factors.

Production Process

-------------------------------------------------------------------

The main equipment of this production line consists of a series of chippers, crushers, dryers, glue mixers, hot presses, etc. The raw materials are chipped and crushed into wood chips of a certain length, and then enter the dryer to dry the excess moisture. Add glue to the dried wood chips and stir them thoroughly. The mixed material can be filled into the mold and hot-pressed. After hot-pressing, the molded molded tray can be taken out.

What Materials Can Make Pallet

-------------------------------------------------------------------

The raw materials for moulded pallets can be waste wood, sawdust, sawdust, shavings, logs, burnt forest, planks, branches, wood chips, waste pallets, etc. and wood processing residues (slabs, slats, garden wood core, waste veneer, etc.). It can also be used for non-wood materials (such as hemp stalk, cotton stalk, reed, bamboo, etc.).

Any raw material rich in fiber can be used to produce pallets, such as straw, waste paper, bamboo, palm tree, coconut, cork, wheat straw, bagasse, miscanthus, etc. Before molding the raw materials, it needs to be crushed to the size required for production, so that the fibers of the raw materials are neat and consistent, and the products are more beautiful.

Customer Photos

Final Wood Pallet Product

-------------------------------------------------------

The molded pallet is a pallet product that is mixed with plant fiber and environmentally friendly synthetic resin and molded in one step by a compressed pallet machine under high temperature and high pressure. The regular size of our pallets is 1200x1200mm.

Pallets smaller than this size can be produced by our standard compressed pallet machine. If larger than this size, our molded pallet machine needs to be customized to meet the needs.

The pallets produced have smooth and flat surfaces, are light in weight, have high load-bearing capacity, do not deform, are anti-breakage, do not require steaming and fumigation, save space, are energy-saving and environmentally friendly, and are suitable for the transportation of various commodities.

Using our company’s production technology, we can produce a variety of pallet types, including nine-feet pallets, Chuan-shaped pallets, Japanese-shaped pallets, tian-shaped pallets, and double-plane pallets. These diverse product types are designed to meet the needs of various industries and scenarios, such as on the racking, roller conveyor, and palletizing into two or three layers.

We can provide automatic production solutions, including automatic metering and feeding, automatic mixing, discharging, feeding, pre-warning of material shortage, and other six automation technologies, saving labor and operation. It can effectively realize 24-hour operation.

Product Paramenters

|

Model

|

PM-1000

|

PM-1000D

|

|

|

Voltage

|

Customized

|

|

|

|

Capacity

|

324 pcs/day (24 hours)

|

432 pieces/day (24hours)

|

|

|

Power

|

18.5 kW

|

22 kW

|

|

|

Hydraulic cylinder diameter

|

350 mm

|

|

|

|

Hydraulic cylinder quantity

|

4 pieces

|

|

|

|

Pressure

|

0-1000 t (adjustable)

|

0-1200 tons (adjustable)

|

|

|

Shaping cycle

|

160 seconds

|

|

|

|

Weight

|

22 tons

|

37 tons

|

|

|

Dimension

|

2000*1400*3500 mm

|

4800*2100*5250 mm

|

|

Hot Searches