- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEYOND

-

Weight:

-

2000 KG

-

After-sales Service Provided:

-

Video technical support

-

Material:

-

SUS304

-

Operation status:

-

Stable

-

Quality:

-

Hight

-

Processing:

-

Oil

-

Certification:

-

CE ISO9001

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Oil

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEYOND

-

Weight:

-

2000 KG

-

After-sales Service Provided:

-

Video technical support

-

Material:

-

SUS304

-

Operation status:

-

Stable

-

Quality:

-

Hight

-

Processing:

-

Oil

-

Certification:

-

CE ISO9001

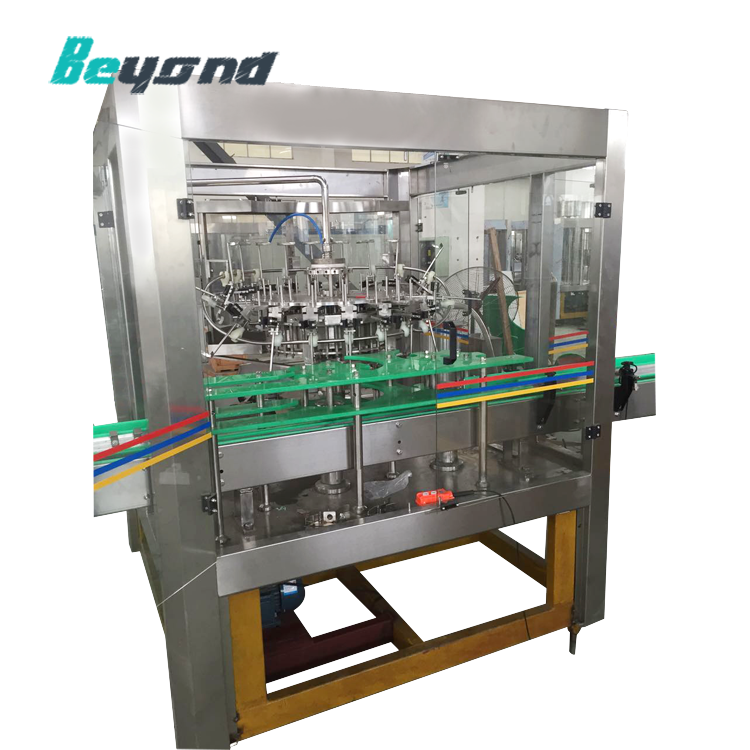

Cooking Oil Filling Packaging Machine

Product Description

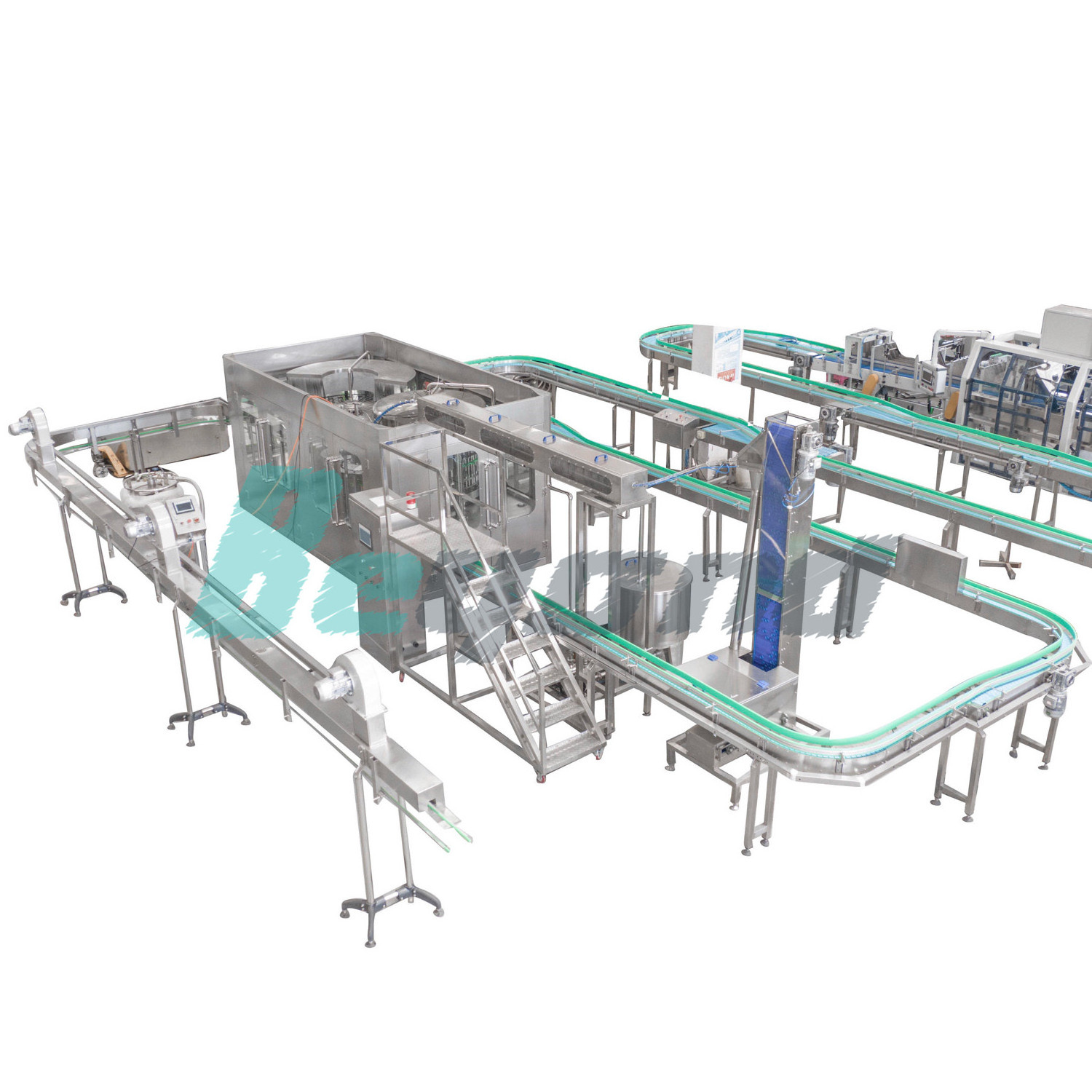

We supply complete solution for the water filling plant ,including Water treatment system / Washing filling capping machine/ Code sprayer / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system

Specification

|

TYPE

|

FILLING HEAD

|

CAPPING HEAD

|

BOTTLE

|

CAPACITY

|

POWER

|

|

CY4

|

4

|

0

|

3L-5L

|

200-300BPH

|

2

|

|

CY6

|

6

|

0

|

3L-5L

|

300-500BPH

|

3

|

|

CY18-6

|

18

|

6

|

200-2000ML

|

2000-3000BPH

|

5

|

|

CY24-8

|

24

|

8

|

200-2000ML

|

4000-5000BPH

|

6

|

|

CY32-10

|

32

|

10

|

200-2000ML

|

6000-7000BPH

|

7

|

|

BY40-40-10

|

40

|

40

|

10

|

18000

|

8.63

|

|

BY50-50-12

|

50

|

50

|

12

|

20000

|

11

|

Water treatment part

According to customer's water source analysis report and the final water standard required ,we will suggest customer to choose thesuitable water treatment plants.

1. This type of oil filling machine is mainly suitable for all sorts of viscous and nonviscous, erosive liquid, such as plant oil

chemical, liquid, daily chemical industry.

2. This machine integrates filling and capping in one machine.

3. This Liquid Filling Machine adopts low vacuum filling to ensure filling accurately without bubble of leakage.

4. Cap screwing device adopts assorted magnetic pieces-structure to avoid damaging the cap when screwing it on the bottle.

5. The machine will do filling and cap-screwing when there are bottles on the work position and it will not do filling and

cap-screwing when there is not any bottle.

6. It needs to change the bottle conducting board when another kind of bottle is used in production.

7. The machine is easy to operate and to change for different kinds products.

8. It is applicable to the production of glass bottle and plastic bottles.

9. Using microcomputer PLC programmable control system of MITSUBISHI, air course system using AIRTAC Taiwan production, SUS304

material for filling valve Material of the filling valve can also be customized according to customer requirements to ensure

quality of the filling machine.

10. It has applied German technique on photoelectric sensors.

11. There is a switch for step progressive type supply and continuous supply. It can be set optionally.

12. It can be installed with the CIP cleaning system according to customer requirement.

9. Using microcomputer PLC programmable control system of MITSUBISHI, air course system using AIRTAC Taiwan production, SUS304

material for filling valve Material of the filling valve can also be customized according to customer requirements to ensure

quality of the filling machine.

10. It has applied German technique on photoelectric sensors.

11. There is a switch for step progressive type supply and continuous supply. It can be set optionally.

12. It can be installed with the CIP cleaning system according to customer requirement.

|

Configuration list

|

supply

|

Brand

|

|

No. Name

|

Manufacturer

|

Remark

|

|

1 Main motor

|

Wannan

|

stand

|

|

2 Rinsing pump

|

Nanfang pump

|

stand

|

|

3 Liquid input pump

|

Nanfang pump

|

stand

|

|

4 transducer

|

Mitsubishi

|

Electric cabinet

|

|

5 PLC

|

Mitsubishi

|

Electric cabinet

|

|

6 Cable

|

China

|

Connection cable

|

|

7 AC contactor

|

siemens

|

Electric cabinet

|

|

8 thermo relay

|

Schneider

|

Electric cabinet

|

|

9 buzzer

|

Taiwan

|

Electric panel

|

|

10 Proximity switch

|

China

|

Cap-feeder and cap tester

|

|

11 Photoelectric switch

|

China

|

Cap testing system

|

|

12 Photoelectric switch

|

China

|

Cap unscrambling system

|

|

13 Photoelectric switch

|

China

|

Bottle stopping system

|

|

14 Liquid level switch

|

Taiwan

|

Hydraulic cylinder

|

|

15 Magnetic valve

|

Airtac

|

Filling valve

|

Labeling packing part

We provide the better solution for the final product package ,a

s customer request and market demand

We have various kinds of options .Labeling machine have the PVC sleeve label ,BOPP hot glue label,Adhesive stick label ,Wet glue label ,and packing machine have the film shrink machine and carton box package.

Conveyor system part

We design the layout of the factory according to the scale of the customer's factory. The whole design adopts famous brand motor and automatic lubrication system, which consumes less electricity and saves space.

Bottle blowing part

This machine is fully automatic, intelligent, stable and reliable pulp blowing machine, simple structure, low energy consumption. It is very popular and widely used in food, beverage, cosmetics, pharmaceutical and other industries.

Hot Searches