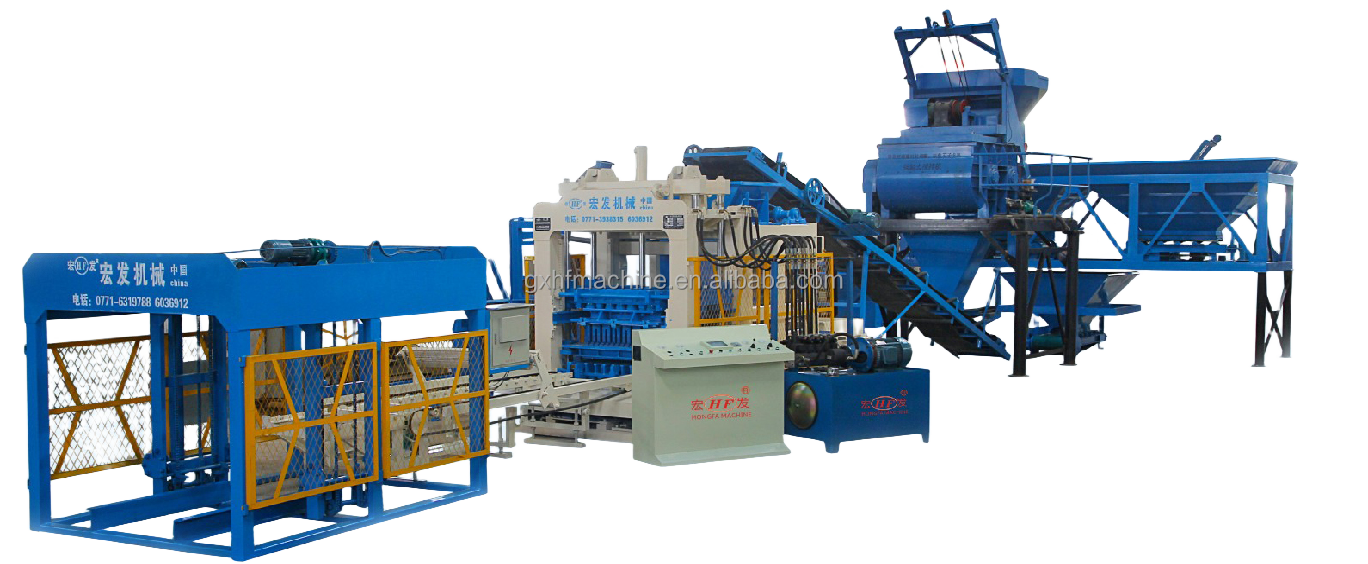

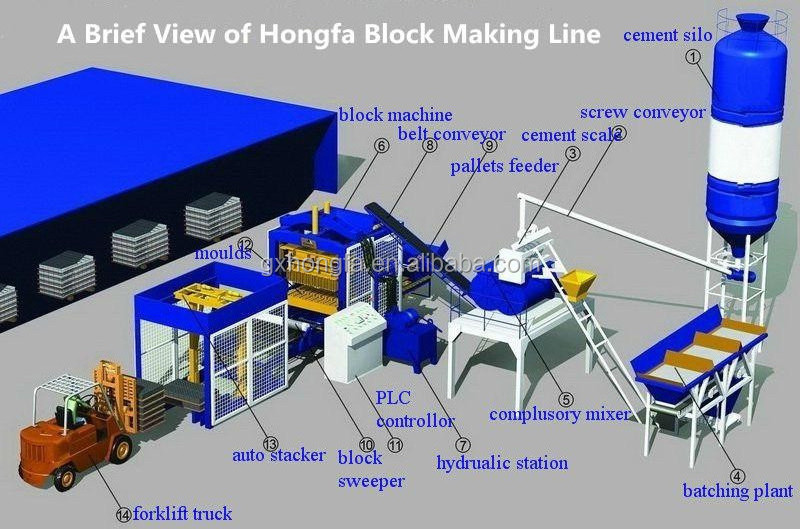

It adopts PLC intelligent control system, which make machine easy to operate, and high-efficiency, t

he bricks produced are better quality - higher density and strength.

We are

Real Factory

, can offer you

Best Price

and

Technical support

on machine