- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 2.5 mm

-

Heating Power (kW):

-

40 kW

-

Air Comsumption(L/min):

-

0.01 L/min

-

Water Comsumption(L/min):

-

0.01 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UNITY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

L7500*W2000*H2000 mm

-

Weight (T):

-

7 T

-

Production capacity:

-

200-400kg / h

-

Twin Screw Max Speed:

-

550r/min

-

Extrusion method:

-

ABCA

-

Production rate (mold/min):

-

40-50

-

Control:

-

PLC touch screen

-

Servo motor:

-

Double servo

-

Screw heat treatment:

-

Carburizing and grinding teeth

-

Gear box:

-

Helical gear

-

Drive:

-

Hydraulic transmission

-

Die design:

-

Six-sided hard chrome plating and polishing

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Max.Forming Height(mm):

-

80 mm

-

Forming Width (mm):

-

780 mm

-

Forming Length (mm):

-

300 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 2.5 mm

-

Heating Power (kW):

-

40 kW

-

Air Comsumption(L/min):

-

0.01 L/min

-

Water Comsumption(L/min):

-

0.01 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UNITY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

L7500*W2000*H2000 mm

-

Weight (T):

-

7 T

-

Production capacity:

-

200-400kg / h

-

Twin Screw Max Speed:

-

550r/min

-

Extrusion method:

-

ABCA

-

Production rate (mold/min):

-

40-50

-

Control:

-

PLC touch screen

-

Servo motor:

-

Double servo

-

Screw heat treatment:

-

Carburizing and grinding teeth

-

Gear box:

-

Helical gear

-

Drive:

-

Hydraulic transmission

-

Die design:

-

Six-sided hard chrome plating and polishing

-

Marketing Type:

-

Hot Product 2021

Product Overview

Disposable fast food container making machine PLA corn starch biodegradable tray thermoforming machine

Disposable biodegradable plastic corn starch PLA 3-touch tableware lunch box food container tray plates making machine production line

the whole line includes three sets of machine:

1.PLA, PP, Corn Starch, talcum powder mixing machine

2.Granule machine

3.One-step tableware forming machine

the whole line includes three sets of machine:

1.PLA, PP, Corn Starch, talcum powder mixing machine

2.Granule machine

3.One-step tableware forming machine

1.PLA, PP, Corn Starch, talcum powder mixing machine

The mixing machine is used to mix PLA, polypropylene release agent, pp, straw granule and talcum powder with certain proportion,

after these raw material mixed each other, they will be make granule through granulator.

The mixing machine is used to mix PLA, polypropylene release agent, pp, straw granule and talcum powder with certain proportion,

after these raw material mixed each other, they will be make granule through granulator.

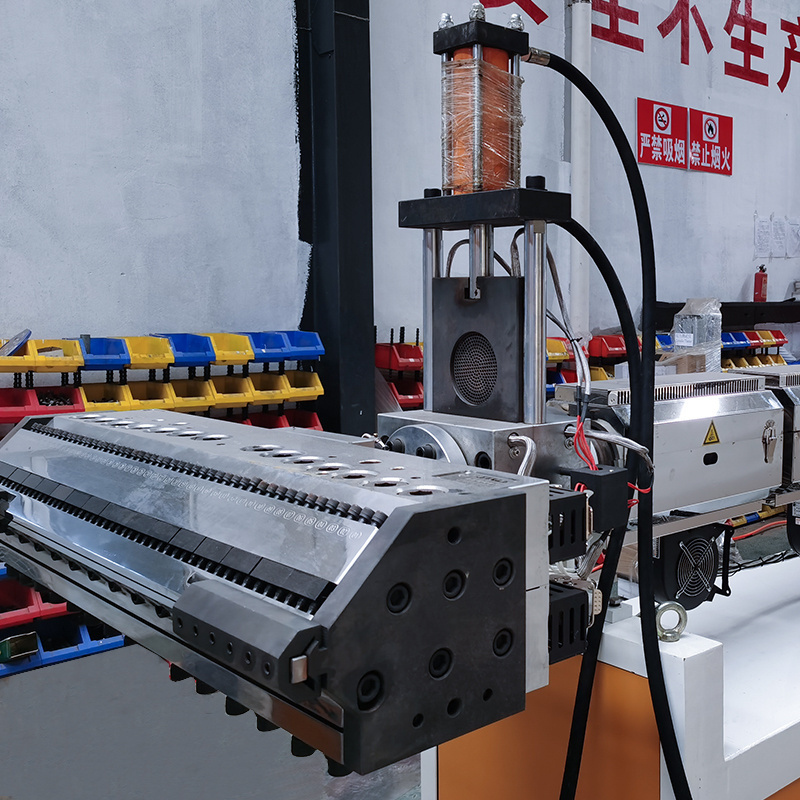

2. Granulator

It is mainly used to extrude the finished-mixing material which will be heated and melted in the barrel, and the melted material is cooled into strip with fan, the cutter will cut these strips into granules.

It is mainly used to extrude the finished-mixing material which will be heated and melted in the barrel, and the melted material is cooled into strip with fan, the cutter will cut these strips into granules.

|

Item

|

Value

|

|

Group capacity

|

200-400kg / h

|

|

Twin-screw Nominal Diameter

|

62.4mm

|

|

Twin-screw host driving power

|

55Kw

|

|

Twin Screw Max Speed

|

550r/min

|

3. One-step tableware forming machine

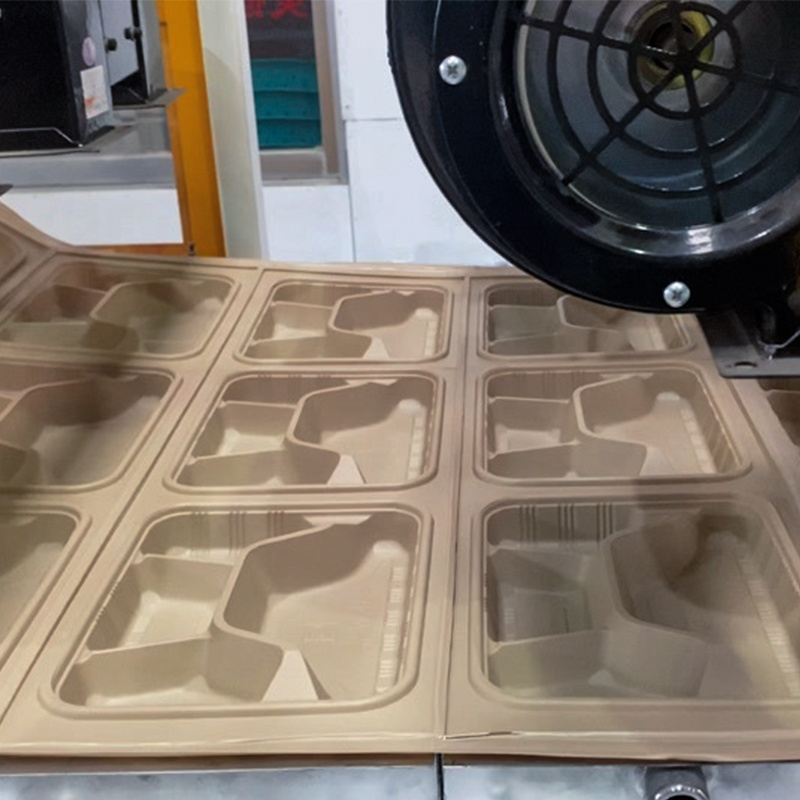

One-step tableware forming machine will make the finished granules form tableware through heating, This machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

One-step tableware forming machine will make the finished granules form tableware through heating, This machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

Precessing Raw Material Available

Biodegradable PBAT

Talcum Master Batch

Grain Filber

Color Master

Calcium Carbonate

Wheat Straw

Bombo Filber

PLA

Bagasse

The following is DY-90-80-65 specification

|

Item

|

Unit

|

Value

|

|

Screw 1

|

mm

|

90

|

|

Screw 2

|

mm

|

80

|

|

Screw 3

|

mm

|

65

|

|

Extrusion capacity

|

kg/h

|

270-320

|

|

Mold size

|

mm

|

250-780

|

|

Equipment size

|

mm

|

7500*2000*2000

|

|

Machine weight

|

ton

|

7

|

Products Show

Our Advantages

1. Low cost for starting: Each production line is equipped with the necessary equipment for the production of products: plate extruder, molding machine, automatic hydraulic punch, blender, grinder, custom mold and a punch knife.

2. Low energy consumption:

The plate extruder can directly complete the forming and punching of products. The product does not need secondary heating.

The plate extruder can directly complete the forming and punching of products. The product does not need secondary heating.

3. Can process various materials: PP and calcium, rice shell, bamboo, talcum, starch, rice straw, bamboo and other plant fibers and so on

4. Adapt Plastic Free Material: PLA, PBAT etc.

4. Adapt Plastic Free Material: PLA, PBAT etc.

5. Various production specifications: By changing the mold, we can produce lunch boxes, food containers, flip boxes, market trays, food trays, bowls, plates, etc. All our molds can be customized according to

customer needs.

6. Highly automated and Easy to operate: Two workers are able to operate the full line each shift. One worker is

for packing and the other is for side material re-usage.

7. All materials can be recycled: Side materials can be crushed and

reused. And there is no gas pollution and no water pollution in the production process.

reused. And there is no gas pollution and no water pollution in the production process.

8. Durable and stable operation: The machine can run all day without any problems. Only basic maintenance is required.

FAQ

Q:Why I choose your company?

A:a) We are the Leading PLA and foam lunch box machine Manufacturer in China.

b) We have made PLA and foam lunch box machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

b) We have made PLA and foam lunch box machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

Hot Searches