- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shandong, China

-

Product name:

-

black film faced plywood

-

Certification:

-

FSC,ISO

-

Size:

-

1220x2440mm as Request

-

Thickness:

-

9mm/12mm/15mm/18mm/21mm/etc

-

Glue:

-

E1/E2

-

MOQ:

-

1*20GP

-

Delivery time:

-

15-20 Days

-

Reuse rate:

-

8-15 times

-

Keywords:

-

Comercial Plywood

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Office Building, Building Construction, Office Building, Building Construction

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shandong, China

-

Product name:

-

black film faced plywood

-

Certification:

-

FSC,ISO

-

Size:

-

1220x2440mm as Request

-

Thickness:

-

9mm/12mm/15mm/18mm/21mm/etc

-

Glue:

-

E1/E2

-

MOQ:

-

1*20GP

-

Delivery time:

-

15-20 Days

-

Reuse rate:

-

8-15 times

-

Keywords:

-

Comercial Plywood

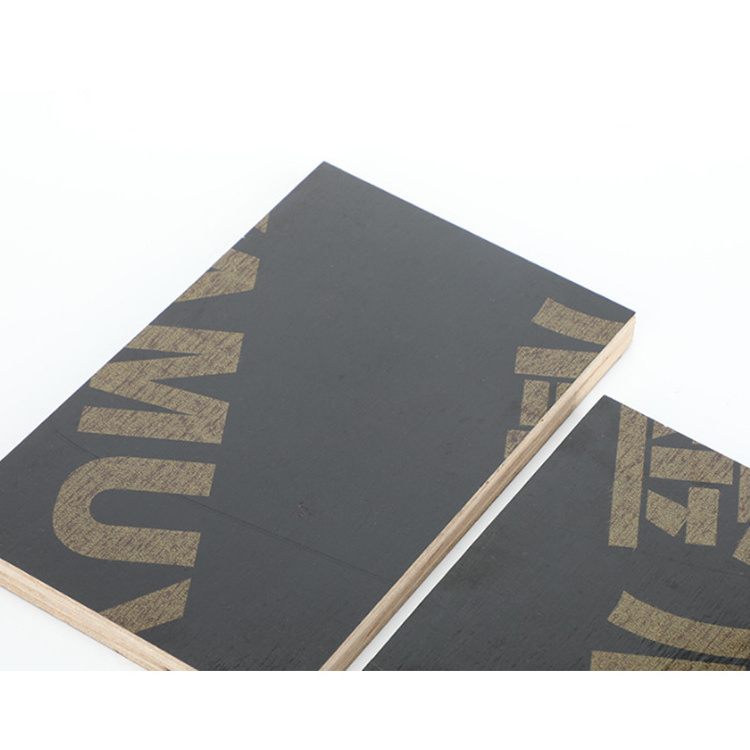

Specification

|

Product name

|

4x8 feet 12mm 15mm 18mm 21mm poplar core plywood board sheet black film faced marine plywood for concrete formwork

|

|

Application

|

Office Building, Concrete Construction

|

|

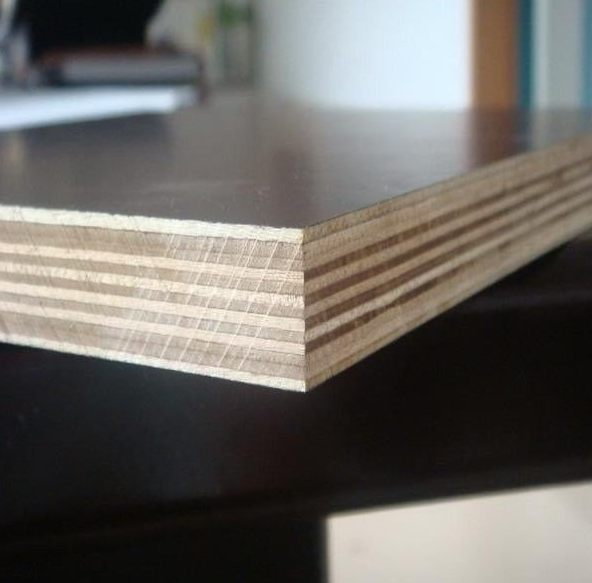

Face/back

|

Film Face/BLACK/BROWN/RED FILM

|

|

Size

|

1220x2440mm/1250x2550mm/as Request

|

|

Thickness

|

9mm/12mm/15mm/18mm/21mm/etc

|

|

Thickness Tolerance

|

± 0.5 mm

|

|

Glue

|

E1/E2

|

|

Core

|

Poplar, eucalyptus

|

|

Moisture Content

|

8%~15%

|

|

Certificate

|

FSC,ISO

|

|

MOQ

|

1*20GP

|

|

Delivery time

|

15-20 Days

|

Advantages:

1. Uniform thickness, smooth surface, high temperature and water-resistance, high strength bonded layer

2. Choosing grade A full piece veneers, making first-class multilayer plywood

3. Wear-resistance, anti-cracking, repeat using 10~15 times for a class board

4. Customized according to personality requirements, special engineering projects

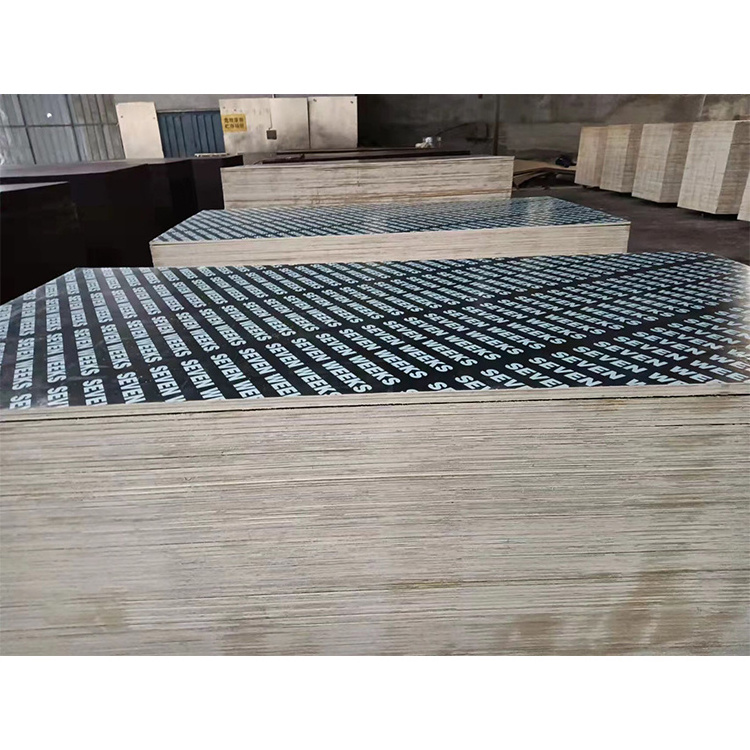

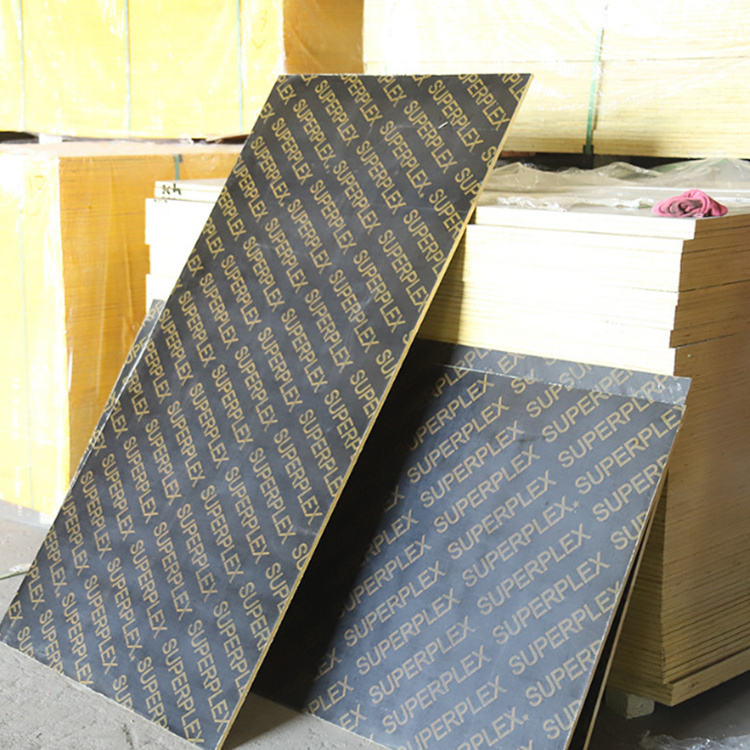

Product Description

Film faced plywood

Film faced plywood is well-known as formwork plywood, especially engineered for the concrete formwork. This plywood is based on Exterior WBP (Water Boiled Proof) glue plywood. Using very special lamination line and presses phenolic film is glued on both sides of plywood. Film Faced plywood is extremely durable in severe conditions such as concrete forming, flooring, trucks parts,etc.

Film Faced Plywood as One of the most popular building material for concrete construction .it is a reusable panel with waterproof film on both sides ,can dimension of the wall , because of different wood species&quality inside the plywood ,the reusable time from 10-60 times , but the weight around 30kg which is much less than the iron and steel which in same dimension .

Low carbon environmental protection, bending, compression, wear resistance, falling, moisture resistance and wear resistance,Easy to use: the surface of the pouring object is smooth and beautiful, minus the secondary plastering process of the wall, which can directly decorate the surface and shorten the construction period.

Process display

Application products

Hot Searches