- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customerized

-

Dimension(L*W*H):

-

according to capacity

-

Weight:

-

10000 KG

-

Marketing Type:

-

Hot Product 2022

-

Machine name:

-

palm oil processing machine price

-

Raw material:

-

palm fruit and palm kernel

-

Function:

-

press palm fruit and palm kernel into oil

-

Machine Material:

-

SS and carbon steel

-

heating method:

-

steam heating

-

installation:

-

our engineer will come for field installation

-

Main Market:

-

South Asian, African countries

-

Advantage:

-

High Oil Output

-

payment terms:

-

TT or LC

Quick Details

-

Production Capacity:

-

1-1000TPD

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GASHILI

-

Voltage:

-

380V or customerized

-

Dimension(L*W*H):

-

according to capacity

-

Weight:

-

10000 KG

-

Marketing Type:

-

Hot Product 2022

-

Machine name:

-

palm oil processing machine price

-

Raw material:

-

palm fruit and palm kernel

-

Function:

-

press palm fruit and palm kernel into oil

-

Machine Material:

-

SS and carbon steel

-

heating method:

-

steam heating

-

installation:

-

our engineer will come for field installation

-

Main Market:

-

South Asian, African countries

-

Advantage:

-

High Oil Output

-

payment terms:

-

TT or LC

Competitive price palm oil extraction machine

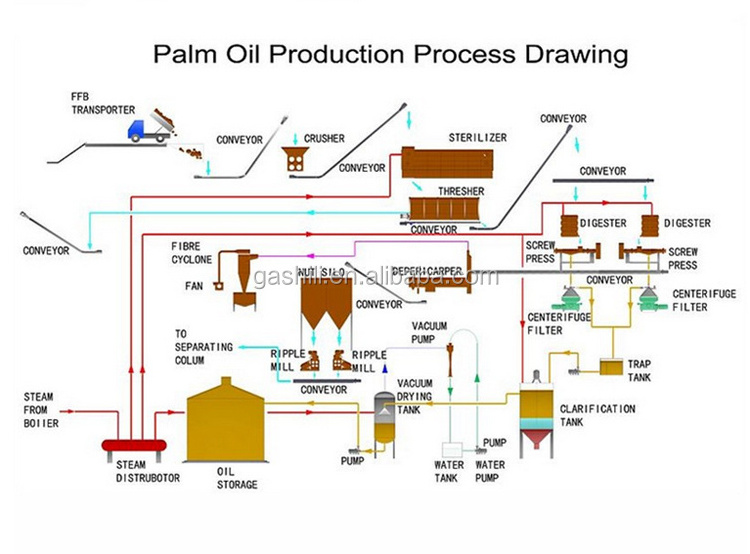

Craft flow:

1.palm fruit/bunch → sterilization → threshing → digesting → clarification → purification→drying → CPO → refining → decolorizing → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

2.palm kernel → crushing → pressing → CPKO → refining → RBDPK oil , RBDPK olein & RBDPK stearin

|

|

Main section |

Main machine |

|

1 |

Fresh palm fruit bunch reception section |

Loading ramp |

|

2 |

Sterilization section |

Sterilization tank |

|

3 |

Threshing section |

Threshing Machine c/w Platform |

|

4 |

Pressing section |

Screw presser |

|

5 |

Oil clarification section |

Clarification Tank |

|

6 |

Fiber separation section |

Depericarper Column |

|

7 |

Palm kernel recovery section |

Nut sheller |

|

8 |

Engine room |

Diesel generator |

|

9 |

Boiler house |

Boiler |

FFB

FFB means fresh palm fruit bunch.palm fruit can be harvested all the year round. After cutting from palm trees, fresh palm fruit bunch must be processed within 2days. Or the acid value will be high and affect the final palm oil processing machine for sale quality.

1- The first steps is sterilization: becasue the palm fruit bunches are very easy to rancidity, and then enfluence the quality of final crude palm oil, it must be processed with 24 hours.

Sterilization has two important effects: 1) Prevent palm fruits rancidity. 2) Making it is easy to seperate the fruits from bunches.

2- The second step is threshing: using our threshing machine to separate the palm fruits from bunches.

3- The third step is digesting: stripping the fruit and separate the pulp with the fruit, for easier pressing.

4- The fourth step is pressing oil: separate fruit from kernel, get crude palm oil and kernel (send it to kernel recovery section). The kernel will not be broken.

5- The fifth step is vibrating screen machine:

This is to clean the small fibers in the oil, so that can get the cleaning oil. Not separating the kernel from fibers.

6- The sixth steps is Clarification tank:

To using the free settling to let the sands and sludge go down the bottom of the tank. The oil will go out from upside of clarification tank, but there still some small impurities in the oil. Because during the harvest, there are plenty of soil and sands together with the FFB.

If without this step, you can't clean them from palm oil.

7- The seventh steps is plate filter:

Because there are still some small impurities in the CPO, it will use plate filter to remove the smallest impurities.

8- The eighth steps is final oil drying system:

To dry the water in the oil. Under the vacuum condition, the water will become steam with the temperature of 80-100 ℃, then will be taken out by vacuum pump. Because it is vacuum, the oil will not oxidation under the temperature of 100℃ or more temperature.

1. We can manufacture according to your sample, design and technical indexes;

2. We'll provide you the whole programme solution according to ur local customs, oil crops,

local market demand;

3. After sale, we'll send our professionals to install and debug the machineries till you

have learned all by yourself.

Term and condition

1.Payment: T/T 30%-payment, 70% balance before shipment.

2.Delivery time: within 7 days after receiving payment.

3.Shipping tem: FOB,CFR,CIF or according to your request.

Quality Guarantee Terms

Quality guarantee term is for one year. Malfunctions which are caused by machine-self and

quality will be responsible for our manufacturer. Other malfunctions which are caused by

operation mistakes, man-made problems, etc will be responsible for clients-self.

After-sale service

1.Assistance to build factory.

2.Repairing and maintenance if any problem occur in the warranty.

3.Installation and clerks training.

4.Spare and wearing parts for free or with big discount.

Any feedback of machines can be told us,and we will try our best to support.

1. How can we choose the right model number oil press?

You can choose the right model number according to the raw material you use and the output capacity you need.

2. Will you offer training?

Yes, free training will be offered after the installation.

3. Where is your factory?

Our factory is located in Zhengzhou city which is the capital of Henan province, China.

4.Can you install the machine in local place?

We will send our engineers to local place to help installing the machine and provide technical guidance.

5.What our machine can produce?

We have pressing machine, solvent extraction machine, and refinery machine, our press/expeller can get cold pressed oil or hot pressed oil from peanut, sunflower seeds, corn germ, cotton seeds, soy bean, rapeseeds and other oil crops; our solvent extraction line can extracte oil from various cakes by solvent(leaching),like soy cake, peanut cake, sunflower cake and others; Our refining machine can help you get refined oil(decoloring oil, degumming oil, deacid oil), 1st to 4st grade cooking oil as your requirements.

6.What's our factory's ability, what kind of our machine can do?

We can produce all kinds of cooking oil machinery, which includes palm oil production machine, peanut oil production line, soybean oil, cotton oil, sunflwoer oil, corn oil, rice bran oil and other kinds of edible oil production line.

The whole production line includes oil press machine, oil extraction(solvent) machine, oil refining equipment, palm oil fractionation equipment, sunflower oil dewaxing plant, decoloring process machine, deodorization process machine and other machine.