- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Constant use

-

Voltage:

-

380v

-

Power:

-

36kw

-

Weight:

-

630 KG

-

Dimension(L*W*H):

-

700*1200

-

stainless steel:

-

304

Quick Details

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

3 Year

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Constant use

-

Voltage:

-

380v

-

Power:

-

36kw

-

Weight:

-

630 KG

-

Dimension(L*W*H):

-

700*1200

-

stainless steel:

-

304

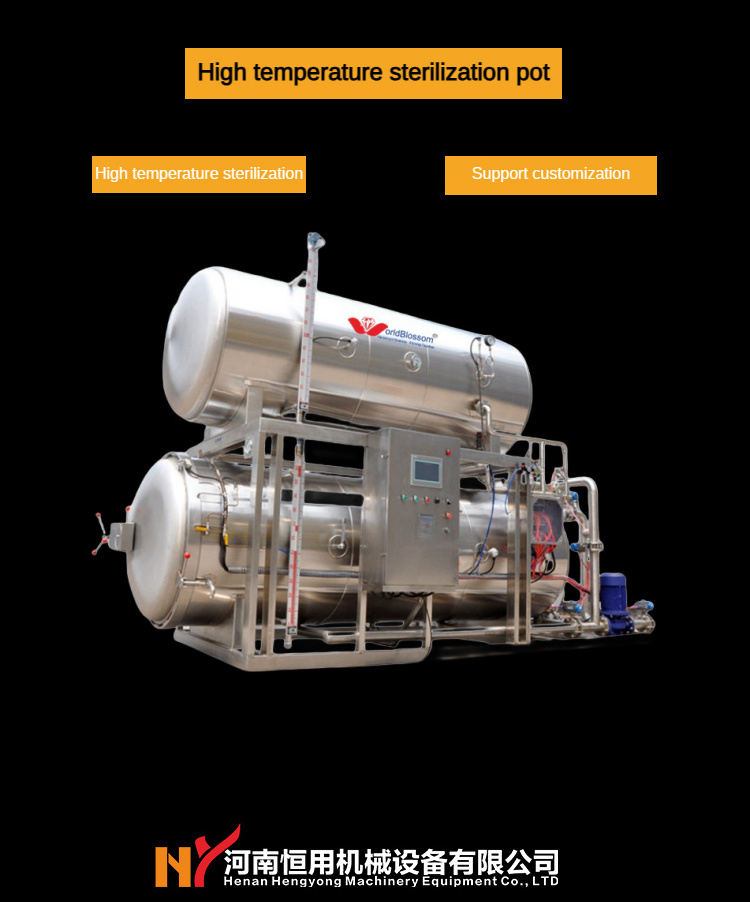

High temperature sterilization pot

1. High temperature short-term sterilization. The high temperature of the process water shortens the heating time and improves work efficiency.

2. Energy conservation. The process water used in the sterilization process can be recycled, saving energy, time, and manpower, and reducing production costs;

3. Stable temperature control. Adopting a newly designed liquid flow switching device, using process water_ The continuous switching circulation flow from top to bottom, left to right eliminates dead corners during the sterilization process, ensuring product quality;

4. The entire sterilization process adopts PLC fully automatic control, and the temperature distribution inside the kettle is controlled within plus or minus 0.5 degrees Celsius, which can be heated in multiple stages and save energy; Equipped with F value measurement function; Can store 100 sterilization formulas

5. For flexible packaging products, especially large bulk packaging, the heat penetration speed is fast and the sterilization effect is good,

6. The entire sterilization process is strictly completed automatically according to the pre-set process formula, which is equipped with multi-level passwords to eliminate the possibility of misoperation;

7. After the device is powered off and restored, the program can automatically return to the pre power off state;

8. The kettle body is insulated with aluminum silicate wool and polyurethane foam, which reduces heat loss and saves steam energy, meeting the requirements of low-carbon and low emissions;

9. There is a triple safety interlock device inside the kettle, which can effectively prevent workers from misoperating and prevent accidents from occurring;

10. Adopting dual safety valves and dual pressure sensing control to eliminate safety hazards

11. According to customer needs, customization can be made for water bath, spray, steam, spray steam,

Products

Equipment category: steam sterilization water bath sterilization spray sterilization

Equipment model: single-layer and double-layer

Equipment model size: Taking 700 as an example, 2800 * 1300 * 2700

Equipment board thickness: Taking 700 as an example, 4mm

Equipment pressure: The design pressure is 0.35. The actual pressure is determined based on the product.

Heating power: single-layer 36KW, double-layer 72KM, taking 700 as an example

Steam usage: Taking 700 as an example, 131KG

Plate size: Taking 700 as an example, 1200 * 450 * 150mm

Number of car trays: Taking 700 as an example, 3 disks, 1 bracket, 1 car

Sterilization output: Taking 700 as an example, approximately 100KG

Pool capacity: Taking 700 as an example, the required cooling pool volume is 1 meter ²

Product details display

Product diversification:

Applicable products:

Workshop and product packaging boxes:

Company personnel structure

Hot Searches