- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

dingchang

-

Surface Treatment:

-

Smooth, spray painted, anti slip

-

Product name:

-

Frp Reinforcing Bar Gfrp Fiberglass Bar Glass Fiber Rebar

-

Material:

-

FRP pultrusion products

-

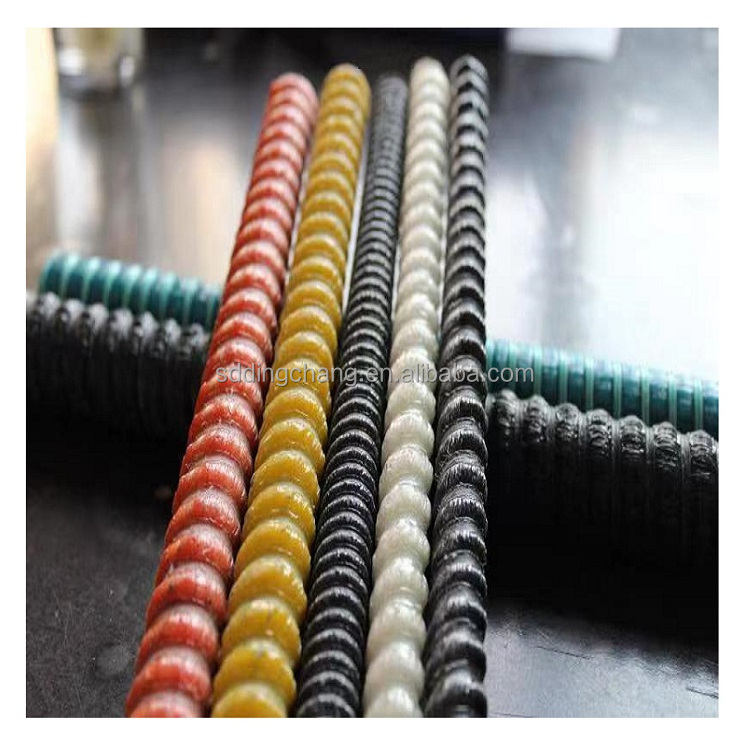

Color:

-

Customization

-

Keywords:

-

Frp Reinforcing Bar Gfrp Fiberglass Bar Glass Fiber Rebar

-

Feature:

-

Flexible,Uv Resistant

-

Type:

-

Fiberglass Fishing Rod, frp Tent Pole

-

Size:

-

Customized

-

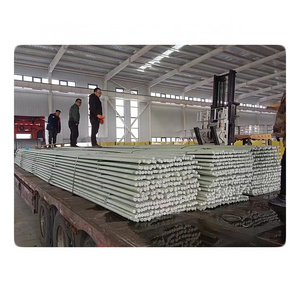

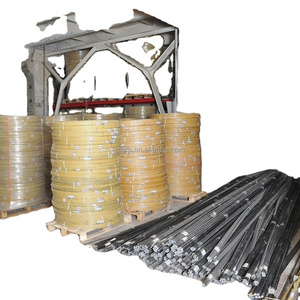

Packing:

-

Pallet

-

Advantage:

-

Lightweight, high strength.

-

MOQ:

-

5000m

Quick Details

-

Application:

-

industry

-

Technique:

-

pultrusion

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

dingchang

-

Surface Treatment:

-

Smooth, spray painted, anti slip

-

Product name:

-

Frp Reinforcing Bar Gfrp Fiberglass Bar Glass Fiber Rebar

-

Material:

-

FRP pultrusion products

-

Color:

-

Customization

-

Keywords:

-

Frp Reinforcing Bar Gfrp Fiberglass Bar Glass Fiber Rebar

-

Feature:

-

Flexible,Uv Resistant

-

Type:

-

Fiberglass Fishing Rod, frp Tent Pole

-

Size:

-

Customized

-

Packing:

-

Pallet

-

Advantage:

-

Lightweight, high strength.

-

MOQ:

-

5000m

FRP REBAR FRP (Fiberglass Reinforced Polymer) Rebar is a spiral wrapped structural reinforcing rod made from a combination of fiberglass roving and resin. FRP Rebar has been developed as a non-corrosive alternative to steel in concrete reinforcement and is suitable for any structural or architectural application where a material that is corrosion resistant, lightweight or non-conductive is required.

BENEFITS FRP Rebar Offers Many Benefits Over Standard Steel Rebar:

BENEFITS FRP Rebar Offers Many Benefits Over Standard Steel Rebar:

• Lightweight (1/4 the Weight vs. Steel Rebar)

• Non-Corrosive & Unsusceptible to Chemical Attack

• Radar Transparent

• Electrically & Thermally Non-Conductive

APPLICATIONS

• Concrete Susceptible to Corrosion

• Tunneling & Mining

• Building & Historic Preservation

• Exposure of Concrete to De-Icing Chlorides

•Masonry Strengthening

• Exposure of Concrete to Marine Chlorides

• Exposure of Concrete to High Voltages & Electromagnetic Fields

|

diameter (mm)

|

Weight per meter(kg)

|

Meters per ton

|

tensile strength Mpa

|

|

8

|

0.1

|

10000

|

≥750

|

|

10

|

0.15

|

6666

|

≥750

|

|

12

|

0.2

|

4762

|

≥750

|

|

14

|

0.28

|

3572

|

≥750

|

|

16

|

0.32

|

3125

|

≥600

|

|

18

|

0.43

|

2326

|

≥600

|

|

20

|

0.55

|

1819

|

≥600

|

|

22

|

0.61

|

1640

|

≥600

|

|

25

|

0.95

|

1053

|

≥600

|

|

28

|

1.15

|

870

|

≥600

|

|

30

|

1.36

|

735

|

≥600

|

|

32

|

1.51

|

663

|

≥600

|

|

34

|

1.71

|

584

|

≥600

|

|

36

|

1.91

|

524

|

≥600

|

Appearance:uniform texture,no bubbles,cracks and other defects affecting strength

Length deviation:±10mm , Diameter deviation:±1,mm

Strainghtening of rod body:≤3mm/m , Ultimate strain:≥1.2 , elastic modulus:≥40Gpa

The FRP rebar produced by aoliande is the full-threaded fiberglass rod made of high-performance glass fiber material, resin matrix and curing agent, etc with a certain proportion.

The FRP rebar produced by aoliande is the full-threaded fiberglass rod made of high-performance glass fiber material, resin matrix and curing agent, etc with a certain proportion.

Due to the similar performance, it has been regarded as the replacement of steel

bars.The All-Thread GFRP bolt was developed for strata support in mining and tunneling as well as for slope and face stabilization.

bars.The All-Thread GFRP bolt was developed for strata support in mining and tunneling as well as for slope and face stabilization.

(1)All-Thread FRP Bolt:The rod is threaded over the whole length, i.e. "All-Thread";

(2)High Corrosion Resistance:The base materials used by the bolt are durable materials, and they are molded through the composite process. The life span is up to 100 years. They can be used as permanent support materials;

(3)High Tensile Strength:The load is approximately double that of a steel bar with the same diameter;

(4)Low Weight:The weight is only 1/4 that of a steel bar with the same diameter. Therefore, the labor intensity is greatly reduced, and the transportation cost is reduced at the same time;

(5)Anti-static:It has no electrical conductivity, and no sparks will be produced when being cut. It is particularly suitable for high gas zones;

(6)Non-flammable: It is non-flammable and has high thermal isolation;

(7)Cuttability: It avoids damages to cutter heads, and does not delay excavation;

As the replacement of steel bars, it has better performance and suitable for so many of fields.

Tensile strength ≥750-1000Mpa, shear strength ≥ 90-110Mpa, elastic modulus ≥ 40-60Gpa, ultimate strain ≥ 1.2

Glass fiber reinforcement has been widely used in many fields which is decided by the characteristics of glass fiber reinforcement. Widely used in subway tunnels (shield), subway continuous walls, retaining piles, coastal engineering, tunnel new construction, pavement deck pavement, airport, dock, station, foundation pit construction, cement products and other fields.

1.The application of glass fiber reinforcement in bridge and road engineering is to solve the problem of corrosion of reinforcement 2.The application of glass fiber reinforcement in concrete structure in offshore area can avoid chloride ion corrosion and reduce the damage of revetment pile, bearing pile and sheet pile.

(3)High Tensile Strength:The load is approximately double that of a steel bar with the same diameter;

(4)Low Weight:The weight is only 1/4 that of a steel bar with the same diameter. Therefore, the labor intensity is greatly reduced, and the transportation cost is reduced at the same time;

(5)Anti-static:It has no electrical conductivity, and no sparks will be produced when being cut. It is particularly suitable for high gas zones;

(6)Non-flammable: It is non-flammable and has high thermal isolation;

(7)Cuttability: It avoids damages to cutter heads, and does not delay excavation;

As the replacement of steel bars, it has better performance and suitable for so many of fields.

Tensile strength ≥750-1000Mpa, shear strength ≥ 90-110Mpa, elastic modulus ≥ 40-60Gpa, ultimate strain ≥ 1.2

Glass fiber reinforcement has been widely used in many fields which is decided by the characteristics of glass fiber reinforcement. Widely used in subway tunnels (shield), subway continuous walls, retaining piles, coastal engineering, tunnel new construction, pavement deck pavement, airport, dock, station, foundation pit construction, cement products and other fields.

1.The application of glass fiber reinforcement in bridge and road engineering is to solve the problem of corrosion of reinforcement 2.The application of glass fiber reinforcement in concrete structure in offshore area can avoid chloride ion corrosion and reduce the damage of revetment pile, bearing pile and sheet pile.

Cooperative brand(International)

Cooperative brand(Domestic)

Quality Satisfied Japan Standard

Hot Searches