- Product Details

- {{item.text}}

Quick Details

-

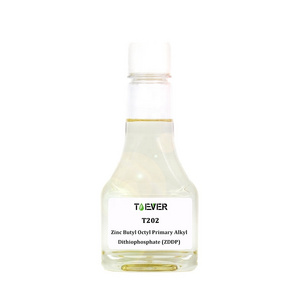

Brand Name:

-

Minglan

-

Model Number:

-

T202

-

Color:

-

yellow

-

Form:

-

Liquid

-

performance 1:

-

anti-oxidation

-

performance 2:

-

anti-corrosion

-

performance 3:

-

antiwear

-

performance 4:

-

extreme pressure

-

Dosage:

-

0.5%-3.0%

Quick Details

-

Application:

-

lubricant oil additive package

-

Type:

-

Antioxidant and anticorrosion additive

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Minglan

-

Model Number:

-

T202

-

Color:

-

yellow

-

Form:

-

Liquid

-

performance 1:

-

anti-oxidation

-

performance 2:

-

anti-corrosion

-

performance 3:

-

antiwear

-

performance 4:

-

extreme pressure

-

Dosage:

-

0.5%-3.0%

|

For specific parameters and content, please communicate with the business. Everything is based on communication between the business and you.

|

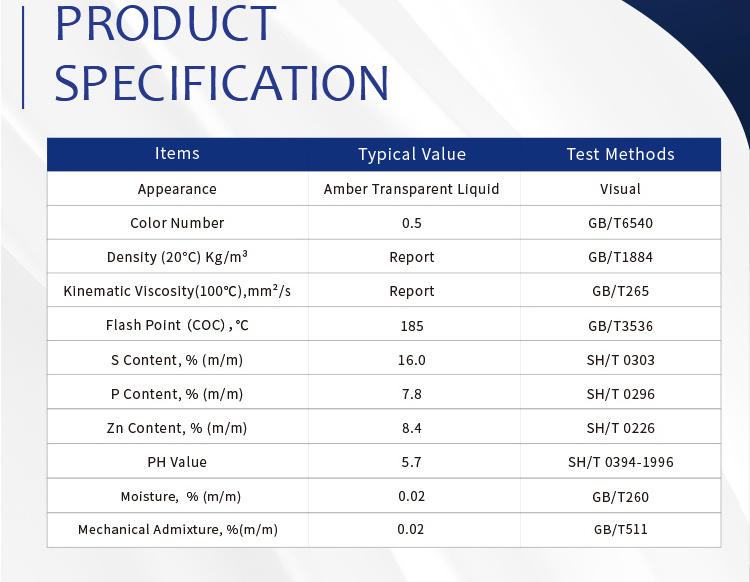

Zinc dialkyl dithiophosphate (ZDDP) is a common type of lubricant additive used to enhance the anti-wear and antioxidant properties of engine oils. It contains zinc and phosphorus components and is known for its ability to form a protective film on metal surfaces, particularly in high-stress areas like engine camshafts and valve trains.

Key functions of ZDDP lubricant additives include:

1. **Anti-Wear Protection:** ZDDP forms a protective layer on metal surfaces, reducing wear and extending the life of engine components.

2. **Oxidation Resistance:** It helps prevent oxidation and degradation of the oil, maintaining its stability over time.

3. **Corrosion Inhibition:** ZDDP provides protection against corrosion, especially in areas where metal surfaces are exposed to harsh conditions.

While ZDDP is effective in enhancing lubricant performance, there has been ongoing consideration of its environmental impact, particularly related to emissions control systems in modern vehicles. In response to emission regulations, some formulations of engine oils have reduced ZDDP levels. It's essential to consider the specific requirements of your engine and follow the recommendations provided by the engine manufacturer and oil supplier.

If you have more specific questions about ZDDP or lubricant additives, feel free to ask for further details.

ZDDP is a very common and effective anti-wear and extreme pressure (EP) additive used in many lubricants, including motor oils,greases, and industrial oils. Here's a breakdown of its key aspects:

Function:

* ZDDP forms a sacrificial film on metal surfaces under high pressure and friction, preventing direct contact and reducing wear.

* It also acts as an antioxidant, scavenging free radicals that can damage the lubricant and engine components.

Benefits:

* Reduced wear and tear: ZDDP significantly extends the life of engine parts like cams, lifters, and valve trains.

* Improved engine performance: By minimizing friction, ZDDP can boost efficiency and power output.

* Protects against extreme pressure: ZDDP is ideal for applications with high loads and contact pressures, like gears and bearings.

Drawbacks:

* Environmental concerns: ZDDP can harm catalytic converters in emissions-controlled vehicles, contributing to air pollution.

* Increased ash content: ZDDP contributes to engine oil's ash content, which can lead to deposit buildup over time.

* Decreased oil life: In high concentrations, ZDDP can shorten the lifespan of the lubricant itself.

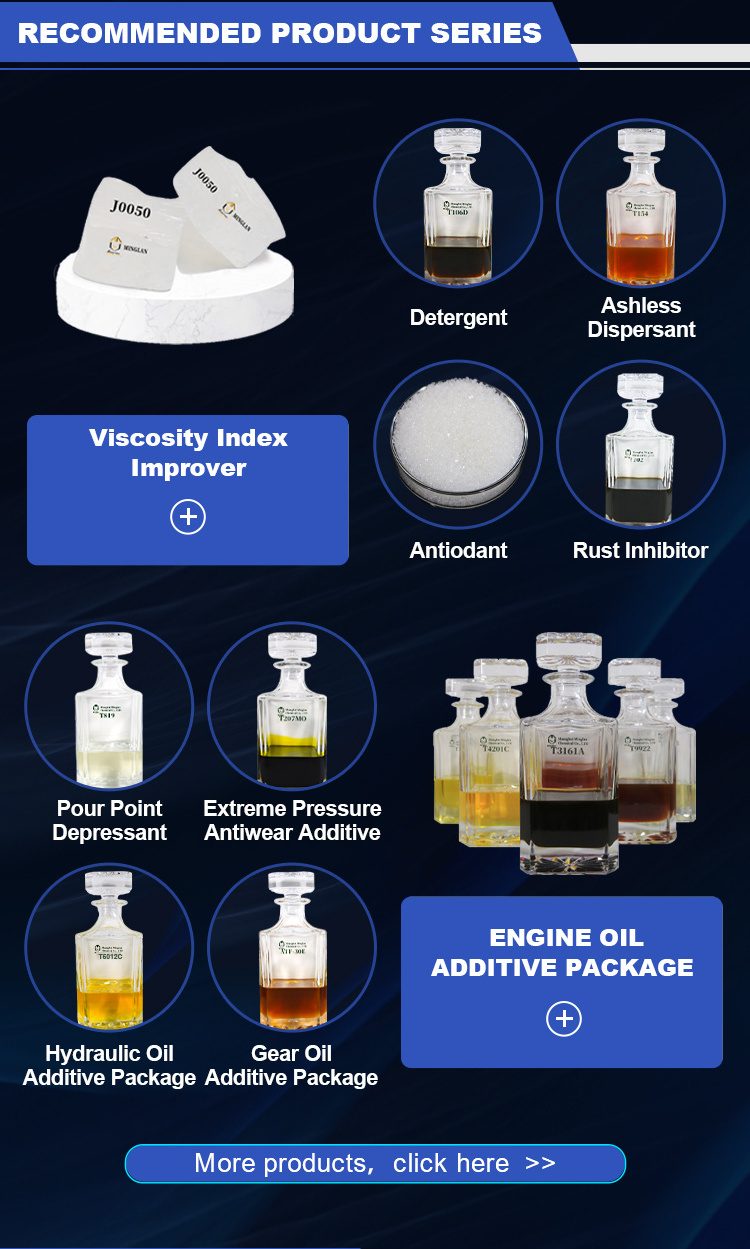

Applications:

* Motor oils: While ZDDP levels have been reduced in modern motor oils due to environmental regulations, it's still present in some formulations, especially for high-performance engines and older vehicles.

* Greases: ZDDP is commonly used in greases for heavy-duty applications like gears, bearings, and chassis components.

* Industrial oils: ZDDP can be found in industrial oils used in gearboxes, compressors, and other machinery operating under demanding conditions.

Overall:

ZDDP remains a valuable lubricant additive despite its drawbacks. The key is to understand its benefits and limitations and use it appropriately based on the specific application and environmental considerations.

Here are some additional points to consider:

* ZDDP concentration: The amount of ZDDP in a lubricant varies depending on its intended use. Higher concentrations offer greater wear protection but may also pose environmental concerns.

* Alternatives: Zinc-free and low-ZDDP lubricants are available for applications where environmental impact is a priority.However, they may not offer the same level of wear protection as ZDDP-containing lubricants.

* Consult your lubricant supplier or manufacturer: They can recommend the best lubricant for your specific needs and equipment, considering factors like operating conditions, engine type, and environmental regulations.

I hope this information provides a comprehensive overview of ZDDP lubricant additives. Feel free to ask if you have any further questions!

Zinc Dialkyl Dithiophosphate (ZDDP) Lubricant Additives:

ZDDP is a very common and effective anti-wear and extreme pressure (EP) additive used in many lubricants, including motor oils,greases, and industrial oils. Here's a breakdown of its key aspects:

Function:

* ZDDP forms a sacrificial film on metal surfaces under high pressure and friction, preventing direct contact and reducing wear.

* It also acts as an antioxidant, scavenging free radicals that can damage the lubricant and engine components.

Benefits:

* Reduced wear and tear: ZDDP significantly extends the life of engine parts like cams, lifters, and valve trains.

* Improved engine performance: By minimizing friction, ZDDP can boost efficiency and power output.

* Protects against extreme pressure: ZDDP is ideal for applications with high loads and contact pressures, like gears and bearings.

Drawbacks:

* Environmental concerns: ZDDP can harm catalytic converters in emissions-controlled vehicles, contributing to air pollution.

* Increased ash content: ZDDP contributes to engine oil's ash content, which can lead to deposit buildup over time.

* Decreased oil life: In high concentrations, ZDDP can shorten the lifespan of the lubricant itself.

Applications:

* Motor oils: While ZDDP levels have been reduced in modern motor oils due to environmental regulations, it's still present in some formulations, especially for high-performance engines and older vehicles.

* Greases: ZDDP is commonly used in greases for heavy-duty applications like gears, bearings, and chassis components.

* Industrial oils: ZDDP can be found in industrial oils used in gearboxes, compressors, and other machinery operating under demanding conditions.

Overall:

ZDDP remains a valuable lubricant additive despite its drawbacks. The key is to understand its benefits and limitations and use it appropriately based on the specific application and environmental considerations.

Here are some additional points to consider:

* ZDDP concentration: The amount of ZDDP in a lubricant varies depending on its intended use. Higher concentrations offer greater wear protection but may also pose environmental concerns.

* Alternatives: Zinc-free and low-ZDDP lubricants are available for applications where environmental impact is a priority.However, they may not offer the same level of wear protection as ZDDP-containing lubricants.

* Consult your lubricant supplier or manufacturer: They can recommend the best lubricant for your specific needs and equipment, considering factors like operating conditions, engine type, and environmental regulations.

I hope this information provides a comprehensive overview of ZDDP lubricant additives. Feel free to ask if you have any further questions!

Hot Searches