- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on the model

-

Weight:

-

KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Mineral processing Continuous Ball Mill machine

-

color:

-

As required

-

quality:

-

China standard

-

installation:

-

offer foundation drawing and full technical help

-

motor:

-

Chinese famous brand or as request

-

Application:

-

beneficiation, mineral processing, ore upgrading, cement making, etc.

-

Keyword:

-

continuous ball mill

-

Test:

-

under engineer's guidance

-

Feeding size:

-

21-38(r/min)

Quick Details

-

Capacity(t/h):

-

1 to 80 Tons per hour

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jinma

-

Dimension(L*W*H):

-

Depend on the model

-

Weight:

-

KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

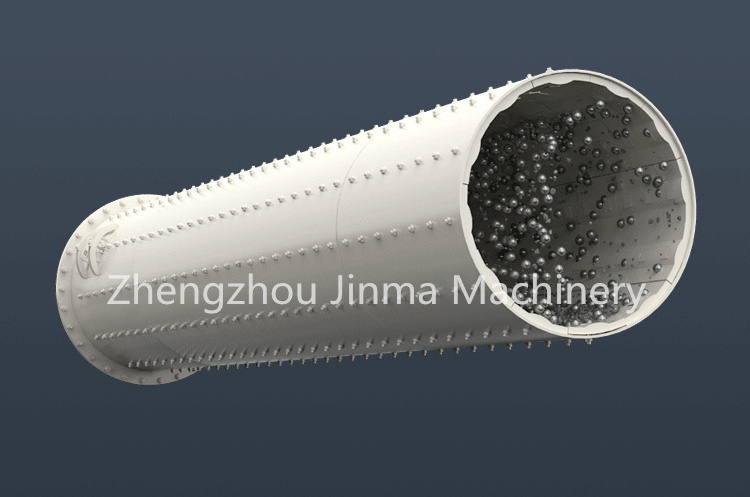

Mineral processing Continuous Ball Mill machine

-

color:

-

As required

-

quality:

-

China standard

-

installation:

-

offer foundation drawing and full technical help

-

motor:

-

Chinese famous brand or as request

-

Application:

-

beneficiation, mineral processing, ore upgrading, cement making, etc.

-

Keyword:

-

continuous ball mill

-

Test:

-

under engineer's guidance

-

Feeding size:

-

21-38(r/min)

Save 20% Electricity Super Energy Saving Ball Grinding Mill

1.MQGZ super energy-saving grinding mill introduction:

The MQGZ super energy-saving ball mill main feature is it changes the edge drive to the drum middle drive; Namely, the normal ball mills’ bull gear is at one side, but the MQGZ ball mills’ bull gears are assembled in the middle of drum, it changes the torque of the drive, greatly reduce the power of 20% to 30%.

2.Super energy saving grinding mill technical parameters

|

Model |

rotation speed(r/min) |

Grinding media (t) |

Feed size(mm) |

Discharge size(mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

|

Φ900×1800 |

38 |

1.5 |

≤20 |

0.075-0.89 |

0.65-2 |

11 |

4.6 |

|

Φ900×3000 |

36 |

2.51 |

≤20 |

0.075-0.89 |

0.8-3.5 |

15 |

5.6 |

|

Φ1200×2400 |

32 |

3 |

≤25 |

0.075-0.6 |

0.9-4.8 |

22 |

12 |

|

Φ1200×3000 |

32 |

3.5 |

≤25 |

0.074-0.4 |

1.2-5.6 |

22 |

12.8 |

|

Φ1200×4500 |

30 |

5 |

≤25 |

0.074-0.4 |

1.5-6 |

30 |

13.8 |

|

Φ1500×3000 |

27 |

7.5 |

≤25 |

0.074-0.4 |

2.5-6.5 |

45 |

15.6 |

|

Φ1500×4500 |

27 |

11 |

≤25 |

0.074-0.4 |

4-10 |

55 |

21 |

|

Φ1500×5700 |

27 |

12 |

≤25 |

0.074-0.4 |

4-13 |

75 |

24.7 |

|

Φ1830×3000 |

24 |

11 |

≤25 |

0.074-0.4 |

5-15 |

90 |

28 |

|

Φ1830×4500 |

24 |

15 |

≤25 |

0.074-0.4 |

5-18 |

90 |

32 |

|

Φ1830×6400 |

24 |

21 |

≤25 |

0.074-0.4 |

6.5-15 |

110 |

34 |

|

Φ1830×7000 |

24 |

23 |

≤25 |

0.074-0.4 |

6-20 |

130 |

36 |

|

Φ2100×3000 |

24 |

18 |

≤25 |

0.074-0.4 |

7-26 |

130 |

34 |

|

Φ2100×4500 |

24 |

24 |

≤25 |

0.074-0.4 |

8-42 |

150 |

42 |

|

Φ2100×7000 |

24 |

26 |

≤25 |

0.074-0.4 |

8-48 |

185 |

50 |

|

Φ2200×4500 |

21 |

27 |

≤25 |

0.074-0.4 |

9-45 |

185 |

48.5 |

|

Φ2200×6500 |

21 |

35 |

≤25 |

0.074-0.4 |

14-26 |

210 |

52.8 |

|

Φ2200×7000 |

21 |

35 |

≤25 |

0.074-0.4 |

15-28 |

245 |

54 |

|

Φ2200×7500 |

21 |

35 |

≤25 |

0.074-0.4 |

15-30 |

245 |

56 |

|

Φ2400×3000 |

21 |

23 |

≤25 |

0.074-0.4 |

8-60 |

185 |

54 |

|

Φ2400×4500 |

21 |

30 |

≤25 |

0.074-0.4 |

8.5-60 |

185 |

65 |

|

Φ2700×4000 |

20.7 |

40 |

≤25 |

0.074-0.4 |

12-80 |

285 |

94 |

3.Super energy saving grinding mill produced