- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Da Tong

-

Year:

-

2018

-

Voltage:

-

220V / 380 V

-

Dimension(L*W*H):

-

2.6 * 1.6 * 1.8

-

Hollow part volume:

-

250

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

95 mm

-

Screw Heating Power(kW):

-

9 kW

-

Extruder Motor Power(kW):

-

3 kW

-

Mold Platen Size(Width)(mm):

-

150 mm

-

Mold Platen Size(Height)(mm):

-

150 mm

-

Air Pressure(MPa):

-

200 MPa

-

Air Comsumption(m³/min):

-

50 m³/min

-

Die Head Heating Power(kW):

-

5 kW

-

Accumulator Capacity(L):

-

50 L

-

Power (kW):

-

17

-

Weight (T):

-

2.3

-

Model Number:

-

KT-10

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Product name:

-

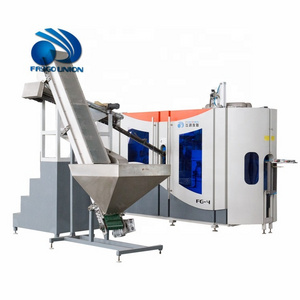

Automatic Blowing Molding Machine

-

Key words:

-

Blowing Molding Machine

-

Name:

-

Plastic Bottle Blow Moulding Machine

-

Material:

-

PP PE HDPE

-

Type:

-

Blow Machine

-

Color:

-

Green

-

Screw Diameter:

-

95 mm

-

Max Cavity:

-

10 L

-

Usage:

-

Big Water Storage Tank

Quick Details

-

Clamping Force (kN):

-

700

-

Output (kg/h):

-

50 kg/h

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Da Tong

-

Year:

-

2018

-

Voltage:

-

220V / 380 V

-

Dimension(L*W*H):

-

2.6 * 1.6 * 1.8

-

Hollow part volume:

-

250

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

95 mm

-

Screw Heating Power(kW):

-

9 kW

-

Extruder Motor Power(kW):

-

3 kW

-

Mold Platen Size(Width)(mm):

-

150 mm

-

Mold Platen Size(Height)(mm):

-

150 mm

-

Air Pressure(MPa):

-

200 MPa

-

Air Comsumption(m³/min):

-

50 m³/min

-

Die Head Heating Power(kW):

-

5 kW

-

Accumulator Capacity(L):

-

50 L

-

Power (kW):

-

17

-

Weight (T):

-

2.3

-

Model Number:

-

KT-10

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Product name:

-

Automatic Blowing Molding Machine

-

Key words:

-

Blowing Molding Machine

-

Name:

-

Plastic Bottle Blow Moulding Machine

-

Material:

-

PP PE HDPE

-

Type:

-

Blow Machine

-

Color:

-

Green

-

Screw Diameter:

-

95 mm

-

Max Cavity:

-

10 L

-

Usage:

-

Big Water Storage Tank

Overview

Products Details

Condition: New

Plastic Processed: PE, HDP

Brand Name: XINHENGDA

Dimension(L*W*H): customized

Warranty: 1 Years

Blow Moulding Type: Extrusion Blow Moulding, . . . . Extrusion Blow Moulding

After-sales Service Provided: Free spare parts, Online support, Field installation, commissioning and training, Video technical support, Engineers available to

service machinery overseas

Weight: Customized

Certification: CE ISO

Layers: 1-5

Capacity: 9-10 L

Color: Customized

Working mode: Automatic

Weight: Customized

Certification: CE ISO

Layers: 1-5

Capacity: 9-10 L

Color: Customized

Working mode: Automatic

Place of Origin: Zhejiang, China

Voltage: 380 v-415 v

Key Selling Points: Energy saving

Applicable Industries: Hotels, Building Material Shops, Food . & Beverage Factory, Farms, Home . .. Use, Construction works

Automatic: Yes

Power: 210 KW

Clamping Force: 200-5000 KN

Product name: Hdpe plastic pallet blow molding . .. . machine/plastic machinery

Material: HDPE

PLC: SIEMENS

Working type: Accumulator

Supply Ability

Su pply Ability: 30 Set/Sets per Month

Packaging & delivery

Port: Shenzhen

|

Quantity(sets)

|

30

|

>30

|

|

Lead time (days)

|

25

|

To be negotiated

|

Details Images

Product Advantage

Blow Machine

Extrusion blow molding machine is used to produce all kinds of the hollow plastic containers for foods, toys, beverages,medicines, chemical products, pesticides &detergents, water bottles, milk bottles, medical bottles, oil bottles, plastic balls,cosmetic bottles, lubricant bottles, plastic containers. The machines are low investment, high efficiency, quick and safe operation, easy for trouble shooting, maintenance and other benefit.

1. CONTROL SYSTEM

Famous brand, true color man-machine controlinterface. Simple and user-friendly page. Easy to operate.

2. EXTRUSION HEAD

Our continous extrusion machine can adopt 1/2/3/4/6 head for wider product application range to fit bottles of different volume,also match with related extrusion system it adopt view stripe head and multi-layer co-extrusion head to fit different f unctional products.

3. CLAMPING UNIT

Its main function is to execute mould carriage up action, mould closing clamping parison action. mould carriaoe down action supply clamping force to offset air blowing pressure. mould open for product de-molding.

4. EXTRUSION SYSTEM

Reasonable head runner design for color change quickly. Die & core individualized according to your product width. Each cylinder at each side for head lifting smoothly.

Specifications

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Packing

Packing Detail:

2.Cartons packed then with wooden pallet.

3.As per customized specifications.

Recommend Products

Why Choose Us

More than 20 years of industry experience

Our company has more than 20 years of industry experience, and many experienced engineers can find industrial chiller suitable for your needs in a short time.

Large inventory

We have industrial chiller of various tonnage and their supporting products. We have built and cooperated with more than 10 warehouses. The number of industrial chillers in the warehouse is large, and we can find the chillers that meet your needs.

Highly professional

We mainly operate injection molding machines ,industrial chillers ,blow machine and so on. We have worked hard for many years to find machines with low price and good quality. We believe that we can succeed only if we are professional.

Custom service

We have a number of professional engineers, which could customize the machine you need according to your needs, and save you money to produce the products you want.

FAQ

FAQ

1. Q: What are your Price Terms and depart port?

A : Trade term: EXW, FOB, or CIF, etc. Shipping port: Shenzhen normally.

2. Q: Why should i choose your company and your products?

A: We have been in this field for more than 20 years,and our quality is good.Due to our good quality ,some of the famous companies are also using our products ,such as ,Mobil,Shell, Castrol,etc.

3. Q:Do you accept customization service?

A:Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Q:What is the order process?

A: Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance payment -packing - delivery - customer receiving - after sale service.

5.Q: I want make a plastic product, but I don't know how to choose a suitable machine model, what should I do?

A: Please feel free to tell us about the product detail information, such as size weight, how many output you prefer per hour. We will help make good proposal with nice price for you.

A : Trade term: EXW, FOB, or CIF, etc. Shipping port: Shenzhen normally.

2. Q: Why should i choose your company and your products?

A: We have been in this field for more than 20 years,and our quality is good.Due to our good quality ,some of the famous companies are also using our products ,such as ,Mobil,Shell, Castrol,etc.

3. Q:Do you accept customization service?

A:Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Q:What is the order process?

A: Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance payment -packing - delivery - customer receiving - after sale service.

5.Q: I want make a plastic product, but I don't know how to choose a suitable machine model, what should I do?

A: Please feel free to tell us about the product detail information, such as size weight, how many output you prefer per hour. We will help make good proposal with nice price for you.

Hot Searches