- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TAIXIANG

-

Product name:

-

gate valve

-

Model:

-

Z45T-16Q

-

Material:

-

cast iron

-

Nominal diameter:

-

DN15-DN1000

-

pressure:

-

6kg, 10kg, 16kg

Quick Details

-

Port Size:

-

DN15-DN1000

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Z45T-16Q

-

Brand Name:

-

TAIXIANG

-

Product name:

-

gate valve

-

Model:

-

Z45T-16Q

-

Material:

-

cast iron

-

Nominal diameter:

-

DN15-DN1000

-

pressure:

-

6kg, 10kg, 16kg

Product introduction

Cast iron gate valve is a kind of valve with the characteristics of small flow resistance, large height, long opening and closing time, etc. The disadvantage is that it is inconvenient to maintain. There are two types of cast iron gate valves: wedge gate valves and parallel gate gate valves.

1. Small flow resistance. The internal medium channel of the valve body is straight, the medium flows in a straight line, and the flow resistance is small.

2. It saves effort when opening and closing. It is compared with the stop valve, because whether it is open or closed, the movement direction of the gate is perpendicular to the direction of medium flow.

3. Large height, long opening and closing time. The opening and closing stroke of the gate is relatively large, and the lowering is carried out through the screw.

4. Water hammer is not easy to occur. The reason is the long shutdown time.

5. The medium can flow in any direction on both sides, making it easy to install. The gate valve passage is symmetrical on both sides.

6. The structural length (the distance between the two connecting end faces of the shell) is small.

7. The sealing surface is easy to wear and affects the service life. When opening and closing, the two sealing surfaces of the gate and the valve seat rub and slide against each other. Under the action of the medium pressure, scratches and wear are easy to occur, which affects the sealing performance and shortens the service life.

8. The price is more expensive. There are many contact sealing surfaces and the processing is complicated. Especially the sealing surface on the gate seat is difficult to process and has many parts.

9. Simple shape, short structural length, good manufacturing process, and wide application range.

10. The structure is compact, the valve has good rigidity, the channel is smooth, and the flow resistance is small. The sealing surface is made of stainless steel and carbide, which has a long service life. It uses PTFE filler, which ensures reliable sealing and light and flexible operation.

|

Valve body, valve cover, gate

|

Stem

|

Sealing surface

|

filler

|

|

chromium nickel titanium stainless steel

|

chromium nickel titanium stainless steel

|

Chrome nickel titanium stainless steel body material

|

PTFE

|

|

|

|

|

|

|

|

|

Hardfacing iron-based alloy

|

|

|

|

|

|

|

|

Chromium Nickel Molybdenum Titanium Stainless Steel

|

Chromium Nickel Molybdenum Titanium Stainless Steel

|

|

|

|

|

|

|

|

|

chromium nickel titanium stainless steel

|

chromium nickel titanium stainless steel

|

Body material

|

|

|

|

|

Overlay welding of cemented carbide

|

|

|

Chromium Nickel Molybdenum Titanium Stainless Steel

|

Chromium Nickel Molybdenum Titanium Stainless Steel

|

Body material

|

|

|

|

|

Overlay welding of cemented carbide

|

|

|

Chromium Nickel Molybdenum Titanium Stainless Steel

|

Chromium Nickel Molybdenum Titanium Stainless Steel

|

Overlay welding of cemented carbide

|

|

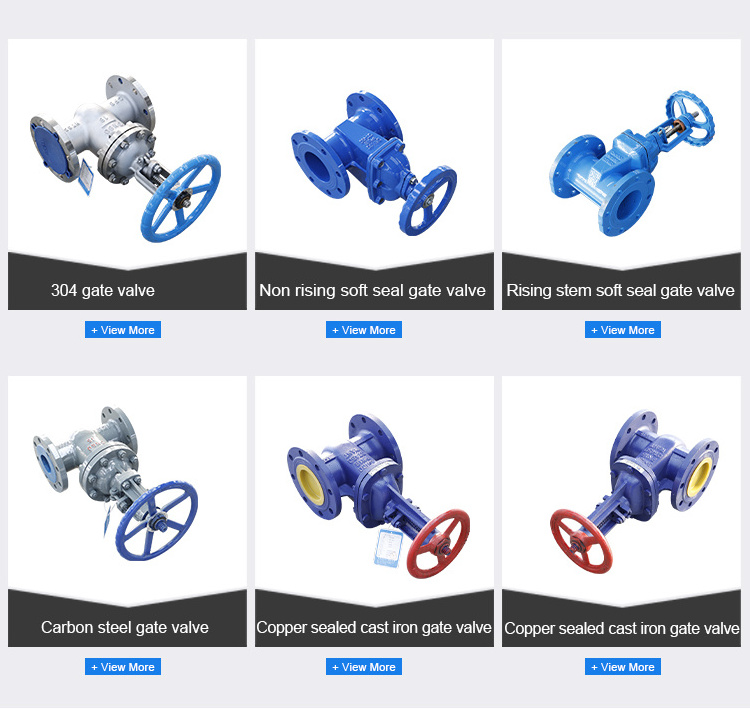

Product show

Product feature

Provide customized services and can customize valves according to customer work needs.

The internal parts are made of corrosion-resistant stainless steel and copper alloy materials, which can be used in sewage systems to adapt to harsh working environments.

Small size, light weight, easy to install maintain.

Has good corrosion resistance and friction resistance. The packing is made of flexible graphite, which has reliable sealing, flexible operation and small opening and closing torque.

Product application

Packing and delivery

Company information

Shandong Taixiang Valve Co., Ltd., we pride ourselves on delivering unparalleled quality and innovation in our valve products. As a professional valve supply chain manufacturer, we specialize in flow gate valves, globe valves, control valves, butterfly valves, ball valves, filters, flanges, pipes, and fittings. Our pressure ranges span from 0.5-10MPA, with diameters ranging from DN15-DN3000, catering to a diverse range of applications and industries.

We recognize the importance of quality and innovation in ensuring our customers’ satisfaction. Our commitment to excellence is reflected in our stringent quality control measures and our dedication to continuous product improvement. Our team of experts is constantly exploring new technologies and materials to enhance the performance and reliability of our valves.

To ensure the highest standards of quality and safety, we hold various certifications, “Valves Control the World, Quality Assures Success” is the core philosophy of our valve company, embodying our mission and commitment.,our Our products are sold to more than 30 countries worldwide, testament to our global reputation for excellence.

At Shandong Taixiang Valve Co., Ltd., we strive to exceed expectations and deliver the best solutions for your valve requirements. We not only provide our clients with high-performance valve products but also offer comprehensive solutions。Choosing our valves means choosing quality assurance and a solid foundation for success. Let’s work together to create a better future。

FAQ

Q: Can you visit your factory

A: Yes, sure. Welcome.

Q: Can you inspect the goods before delivery

A: Yes, sure. Welcome to our factory inspect the goods. Also accept third party inspection, such as SGS, TUV, BV etc.

Q: Can you shorten delivery time?

A: If very very urgent, please confirm with sales. We would like arrange extra-working time for you.

Q: Can you accept OEM?

A: Yes, we can

Q: Can you accept marking our LOGO?

A: Yes, we can

Q : Can I have a sample order for your product?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q: Do you have any MOQ limit for product order?

A: Low MOQ, 1pc for sample checking is available.

Q: How do you ship the goods and how long does it take to arrive?

A: Usually we ship by sea. It usually takes 30 days to arrive. Air shipping also optional.

Hot Searches