The External layer is a standard seal layer of FRP that further protects the structural core from electrolyte splashes and spills. Optionally this external seal may be specified with multi-layered oriented fiber reinforcements to guarantee trouble-free operation in unusually extreme operating environments.

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Tank

-

Applicable Industries:

-

Metallurgical industry

-

Product name:

-

Polymer concrete electrolytic cells

-

Raw material:

-

Polymer concrete

-

Application:

-

Metallurgical industry

-

Dimension:

-

Customized

-

Weight:

-

Customized

-

Manufacture technology:

-

Moulding

-

Advantage:

-

Long service life

-

MOQ:

-

20 sets

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GAINS

-

Weight (KG):

-

1000

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Tank

-

Applicable Industries:

-

Metallurgical industry

-

Product name:

-

Polymer concrete electrolytic cells

-

Raw material:

-

Polymer concrete

-

Application:

-

Metallurgical industry

-

Dimension:

-

Customized

-

Weight:

-

Customized

-

Manufacture technology:

-

Moulding

-

Advantage:

-

Long service life

-

MOQ:

-

20 sets

Product Description

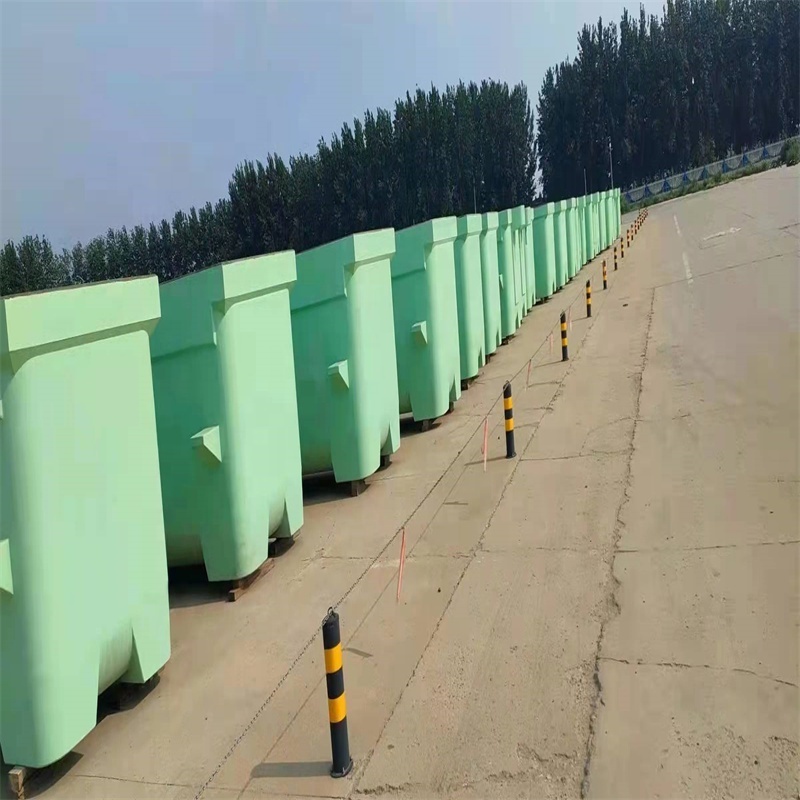

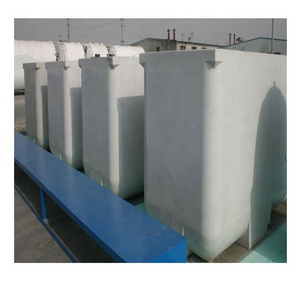

Vinyl ester resin monolithic casting electrolytic cells

Electrolytic cells are designed, built and installed to satisfy the most stringent requirements requested by tank house operators worldwide. In most cases their main request is to guarantee full operating availability throughout the plant's lifespan, maximizing production of high-purity metal (copper, zinc, nickel, cobalt, lead or other nonferrous metals) with absolute safety for people and the environment. Additionally, cells must accommodate changes for continuous improvement of the electrolytic process, integrating efficiently with upgrades of complementary equipment such as anodes, cathodes, cap, boards, overhead crane electrolyte agitation systems, acid mist control devices, thermal insulation among many others.

Structure

Wall Cross Section of Polymer Concrete Electrolytic Cells

Electrolytic cells are cast monolithically based on a patented, three-layer composite material system: The Internal layer is a monolithic tank made with multiple layers of fiber-reinforced vinyl ester resin (FRP) complying with chemical barrier international norms that assure long-term impermeability and corrosion resistance. The intermediate layer is the structural core made with polymer Concrete, with a patented formulation to achieve a low coefficient of thermal expansion, providing long-term structural integrity with low thermally-induced stresses.

Product Advantages

1. Long-term impermeability, free of corrosion, 20+ years warranty

Our monolithic internal tank manufactured with multiple layers of fiber-reinforced premium vinyl ester resin. It has continuous service without leakage, free of corrosion and structural flaws which operating under normal conditions as specified for each project.

2. Swift, accurate and less costly installation

Electrolytic cells include features that allow reduction of 25% or more in time needed for cell erection, alignment and leveling compared to time required with conventional polymer concrete cells. Dimension tolerances for electrolytic cells are consistently tight, simplifying installation in the most demanding applications ,including plants with automated crane systems.

3. Minimum cleaning time and water consumption

The rounded internal shape,optional sloped cell floors, and smooth, flat finish of the internal tank, facilitate water sweeping and drainage of heavy sludge, with reduced water usage and accelerating return to service after each cleaning.

4.

Maximum operational safety

The structural core of electrolytic cells is bolstered with sturdy external seismic reinforcement blocks confining its floor supports, and includes a robust, internal bidirectional, pultruded FRP bar mesh reinforcement which positively maintains integrity should the cell fail due to catastrophic events. Electrolytic cell installation protocols call for lateral wall collaboration between cells,thus reducing stress levels of cell around 40% under normal operating conditions.

The structural core of electrolytic cells is bolstered with sturdy external seismic reinforcement blocks confining its floor supports, and includes a robust, internal bidirectional, pultruded FRP bar mesh reinforcement which positively maintains integrity should the cell fail due to catastrophic events. Electrolytic cell installation protocols call for lateral wall collaboration between cells,thus reducing stress levels of cell around 40% under normal operating conditions.

5. Minimum maintenance cost

The robust, virtually impervious internal tank that is chemically bound to the polymer concrete structural core during molding is tolerant to operating abuse its smooth, non-stick surfaces minimize adhesion of contaminants.

Packing & Delivery

Hot Searches