- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

ball material:

-

carbon steel, S.S. bearing steel,nylon,plastic,stainless steel

-

shell material:

-

carbon/stainless steel,nylon,plastic,bearing steel,304/316/440 steel

-

Customized Products:

-

Available as per drawing or sample or catalogue,Custom sizes, stamping

-

feature:

-

universal ball can turn,gyrate flatten single goo easily

-

apply:

-

Air cargo handling the transfer unit,Heater assembly,Punch,Retooling

-

application:

-

conveyor system feedstock systems machining packing accessory

-

name:

-

Ball transfer unit,ball transfer units,converyor roller,caster wheels

-

use:

-

Air Cargo Facility,Ball frame for glass handing

-

used:

-

glass handling,custom designed ball table,tool charge

-

using:

-

die lifters fitted to bed of 600 ton press,material handling system

Quick Details

-

Warranty:

-

Unavailable

-

Weight (KG):

-

0.2

-

Place of Origin:

-

China

-

Brand Name:

-

OEM

-

ball material:

-

carbon steel, S.S. bearing steel,nylon,plastic,stainless steel

-

shell material:

-

carbon/stainless steel,nylon,plastic,bearing steel,304/316/440 steel

-

Customized Products:

-

Available as per drawing or sample or catalogue,Custom sizes, stamping

-

feature:

-

universal ball can turn,gyrate flatten single goo easily

-

apply:

-

Air cargo handling the transfer unit,Heater assembly,Punch,Retooling

-

application:

-

conveyor system feedstock systems machining packing accessory

-

name:

-

Ball transfer unit,ball transfer units,converyor roller,caster wheels

-

use:

-

Air Cargo Facility,Ball frame for glass handing

-

used:

-

glass handling,custom designed ball table,tool charge

-

using:

-

die lifters fitted to bed of 600 ton press,material handling system

Professional Manufacture for All Various Universal Ball Transfer Unit

Supply Ball Transfer Units for more than 20years. Also we pursue high quality and continuously develop new products. We have automated production equipment production lines, Adequate inventory. Large Stock, Delivery Fast.

Different material and different types, meet different customers inquires.

Material can do carbon steel,stainless steel,plastic,nylon,abs,brass,peek etc.

Types can do pressed,light duty,heavy duty,spring inside,spring outside,thread,hex bolt etc.

Ball Transfer Unit

1)are omni-directional load-bearing spherical balls mounted inside a restraining fixture. They are identical in principle to a ball computer mouse upside-down, or a trackball, except there is an array of them side-by-side.

2)Typically the design involves a single large ball supported by smaller ball bearings.They are commonly used in an inverted ball up position where objects are quickly moved across an array of units, known as a ball transfer table, a type of conveyor system. This permits manual transfer to and from machines and between different sections of another conveyor system.

3)They are used in airports for luggage delivery, or in industry as part of manufacturing systems. Prior to the invention of the ball transfer unit, first patented by Autoset Production Ltd in 1958, these applications were solved by the use of inverted casters.However, casters recognize a trail, meaning that the wheels had to align before directional change could be achieved.Ball transfer units can also be used non-inverted ball down position as a type of caster, however this use is restricted by load-bearing limitations and the type of floor.

4)Manufacturers have addressed this problem with ball transfer units incorporating re-circulating ball principles, however the inverted position is still the most common application and the least problematic.

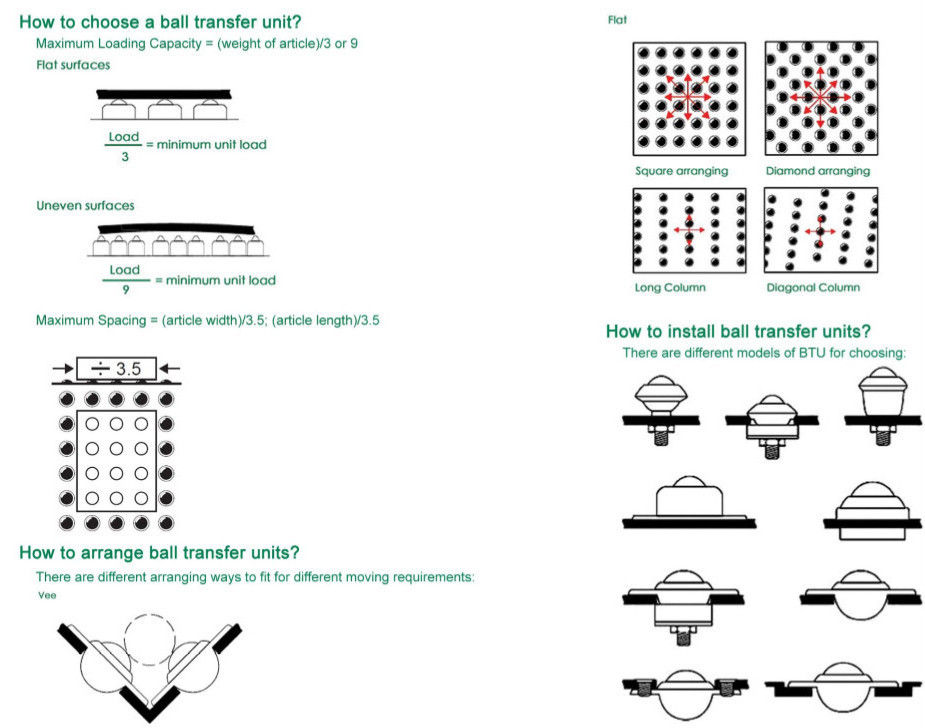

How to choose a ball transfer unit?

Maximum Loading Capacity = (weight of article)/3 or 9

Maximum Spacing = (article width)/3.5; (article length)/3.5

How to arranging and installing ball transfer units?

There are different arranging ways to fit for different moving requirements,different models of BTU fo choosing

Ball Transfer Unit Catalogue:

Skate Wheel:

Applications:

- Typical application in production lines:

- Typical application in goods handling:

Ball transfer units table in Dubai International Airport

Contact: