- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MTF

-

Voltage:

-

220V

-

Weight:

-

500 kg

-

Product name:

-

Automatic Cutting Machine

-

Application:

-

Manufacturing Plant

-

Function:

-

Cutting Material

-

Usage:

-

most kinds of material

-

Certification:

-

CE

Quick Details

-

Type:

-

Paper Cutting Machine

-

Production Capacity:

-

70 m/min

-

Max. workable width:

-

1800

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MTF

-

Voltage:

-

220V

-

Weight:

-

500 kg

-

Product name:

-

Automatic Cutting Machine

-

Application:

-

Manufacturing Plant

-

Function:

-

Cutting Material

-

Usage:

-

most kinds of material

-

Certification:

-

CE

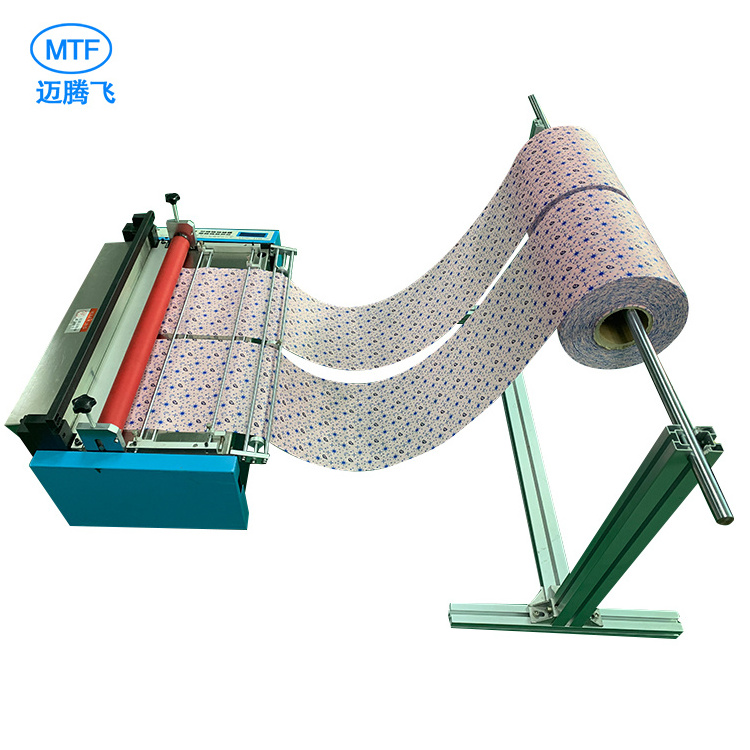

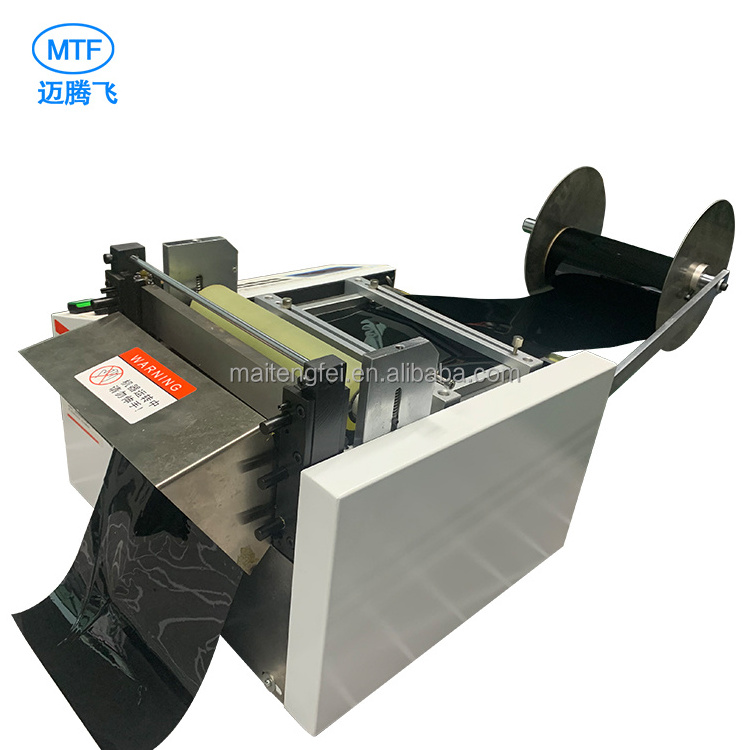

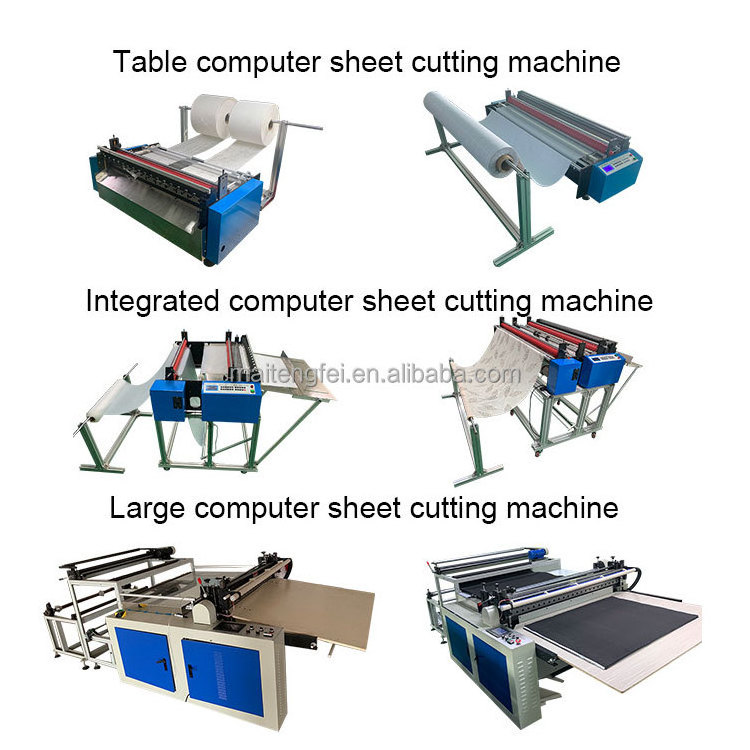

THREE TYPES OF MACHINES

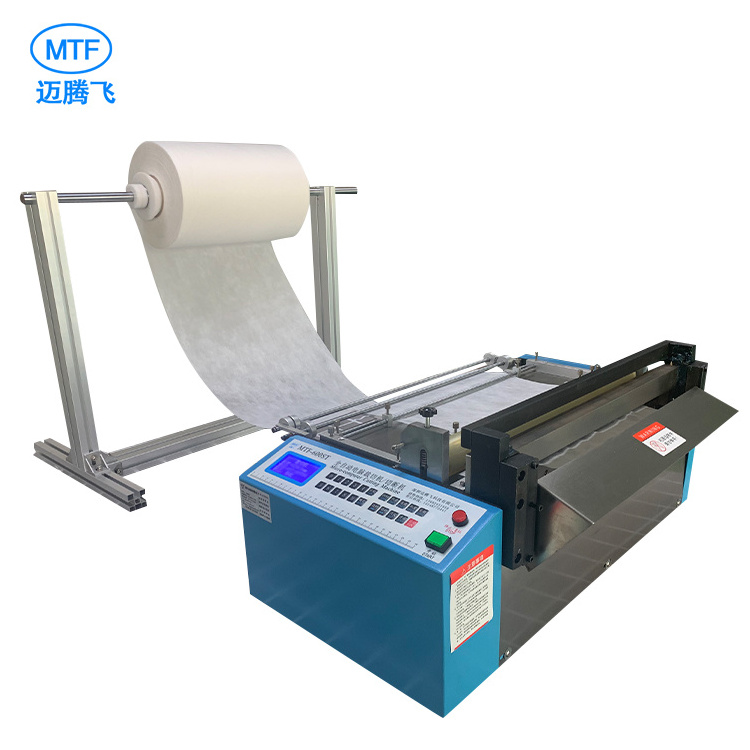

COMPUTER ROLL TO SHEET CUTTING MACHINE

--Plenty of Models in stock

--Short Production Time,Stable ETD

Working Video of Various Computer Sheet Cutting Machine

Support customization,all kinds of material can be cut

PRODUCT PARAMETER

Table Computer Sheet Cutting Mach

ine

--all models in stock

|

MODEL

|

POWER

|

EFFECTIVE WORKABLE WIDTH

|

CUTTING SPEED

/ACCURACY

|

SIZE

|

CUTTING LENGTH

|

N.W.

|

NUMBER OF CUTS

|

|

MTF-100 ST

|

220 V 50/60HZ

|

80 MM

|

Adjustable Cutting Speed

0.1~35000 mm/min

Cutting Accuracy

+/-0.1 mm

|

420*350*390 mm

|

Can be set

from 0.1 mm to 9999.9 mm

|

29kg

|

Can be set

from 1 to 999999

|

|

MTF-200 ST

|

|

180 MM

|

|

350*430*420mm

|

|

43kg

|

|

|

MTF-300 ST

|

|

280 MM

|

|

350*520*430mm

|

|

52kg

|

|

|

MTF-400 ST

|

|

380 MM

|

|

350*600*490mm

|

|

55kg

|

|

|

MTF-500 S

|

|

480 MM

|

|

620*830*500mm

|

|

65kg

|

|

|

MTF-600 S

|

|

580 MM

|

|

380*830*490mm

|

|

85kg

|

|

|

MTF-700 S

|

|

680 MM

|

|

380*930*490mm

|

|

95kg

|

|

|

MTF-800 S

|

|

780 MM

|

|

620*1130*500mm

|

|

150kg

|

|

|

MTF-1000 S

|

|

980 MM

|

|

640*1330*540mm

|

|

250kg

|

|

|

MTF-1200 S

|

|

1180 MM

|

|

640*1530*550mm

|

|

290kg

|

|

|

MTF-1500 S

|

|

1480 MM

|

|

640*1830*540mm

|

|

400kg

|

|

|

MTF-1600 S

|

|

1580 MM

|

|

640*2030*540mm

|

|

450kg

|

|

English and Chinese are Supportable

1)

All digital keys, easy to operate;

2)

LCD--

Simple and straightforward

3)Cutting

Length, Cutting speed,

Batch, Total number of cuts can be set.

Vacuum Heat Treated Steel Knife

1) High-quality SKD-11 high-speed steel knife;

2) Sharp blade, wear-resistant and durable;

3) Keep the incision flat and free of burrs.

Material Rack with Bearing

1) "H"-shaped floor-standing design-stable and strong;

2) Fixed cone-suitable for raw materials roll with various inner diameters.

Youli Feeding Roller

1) Wear-resistant, pressure-resistant and high-temperature resistant;

2) Both ends are equipped with finger-tight pressure

regulating screws;

regulating screws;

3) Effectively prevent the material from slipping

4) Ensure uniform feeding.

High-power Cooling Fan

1)Multiple sets of fans exhaust air to dissipate heat;

2)Can work continuously for a long time;

3)Extend the service life of the machine.

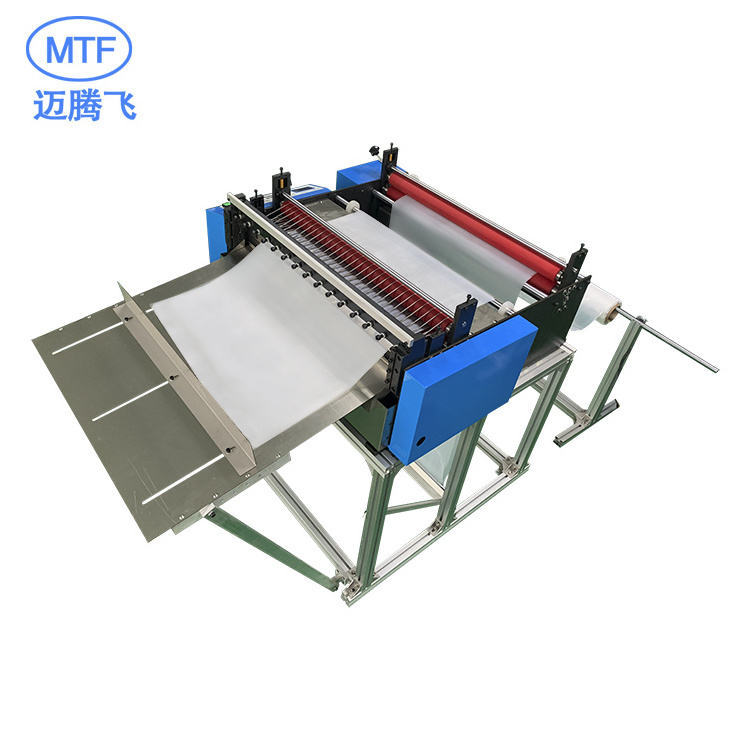

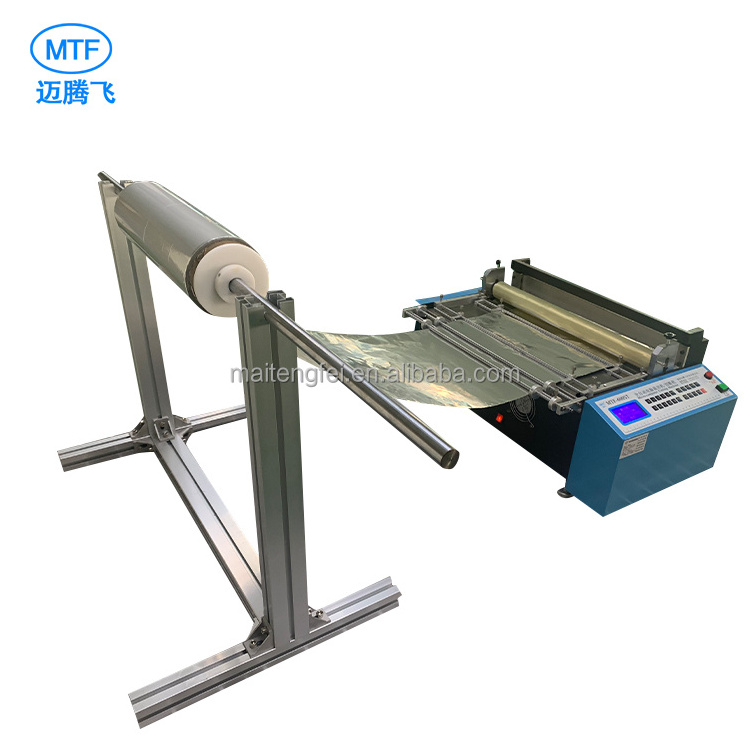

INTEGRATED COMPUTER SHEET CUTTING MACHINE

--most models in sto

ck

.

|

MODEL

|

POWER

|

EFFECTIVE WORKABLE WIDTH

|

CUTTING SPEED

/ACCURACY

|

SIZE

|

CUTTING LENGTH

|

N.W

|

NUMBER OF CUTS

|

|

MTF-400ST

|

220 V 50/60HZ

|

380 MM

|

Adjustable Cutting Speed

0.1~35000 mm/min

Cutting Accuracy

+/-0.1 mm

|

1480*730*1220mm

|

Can be set

from 0.1 mm to 9999.9 mm

|

155kg

|

Can be set

from 1 to 999999

|

|

MTF-500ST

|

|

480 MM

|

|

1480*830*1220mm

|

|

170kg

|

|

|

MTF-600ST

|

|

580 MM

|

|

1480*930*1220mm

|

|

185kg

|

|

|

MTF-700ST

|

|

680 MM

|

|

1480*1030*1220mm

|

|

215kg

|

|

|

MTF-800ST

|

|

780 MM

|

|

1480*1130*1220 mm

|

|

230kg

|

|

|

MTF-1000ST

|

|

980 MM

|

|

1500*1330*1220mm

|

|

340kg

|

|

|

MTF-1200ST

|

|

1180 MM

|

|

1500*1530*1220mm

|

|

380kg

|

|

|

MTF-1500ST

|

|

1480 MM

|

|

1500*1830*1220mm

|

|

470kg

|

|

|

MTF-1800ST

|

|

1780 MM

|

|

1500*2130*1220mm

|

|

560kg

|

|

Integrated Computer Sheet Cutting Machine Compare to Table Ones,There Are More Devices To Ensure Accurate Cutting Results.

Photoelectric Sensor Imported From Germany-Automatic Feeding

Double Feeding Rollers

1) Double feeding rollers are more effective to prevent material from slipping and ensure even feeding

2) The rollers are of good quality, wear-resistant, pressure-resistant and high-temperature resistant

3) Both ends of the two rollers are equipped with hand-tightened pressure regulating screws, which is convenient to adjust

.

Double Correction Device

Dual rectification device, fixed rectification of material rod holder and pull rod guide,

Ensure that the material does not skew during the feeding process

Receiving Device of Cutting Machine

1)

Receiving tray-stack materials neatly , ensure the materials are clean

2)It

can be moved up and down according to the length of the material, and the height of the receiving tray can also be adjusted.

Speed Controller

1)

Knob speed control, speed adjustment at any time, simple and convenient

2)

AC speed regulating motor, stable performance

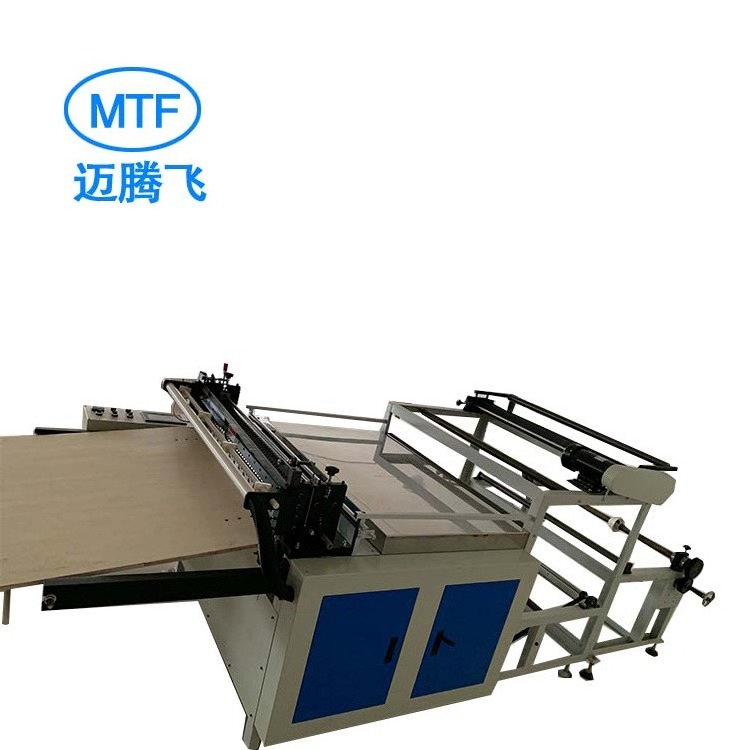

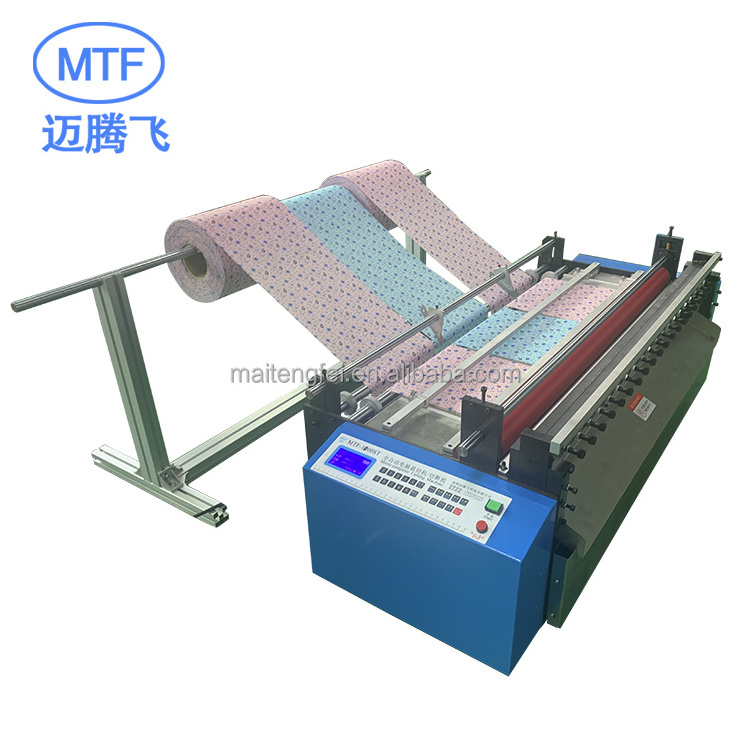

LARGE COMPUTER SHEET CUTTING MACHINE

--UNIQUE DESIGN,SUPPORT CUSTOMIZATION

|

MODEL

|

POWER

|

EFFECTIVE WORKABLE WIDTH

|

CUTTING SPEED

/ACCURACY

|

SIZE

|

CUTTING LENGTH

|

N.W

|

|

MTF-1000 CT

|

|

980 MM

|

Cutting Speed:0.1~70000 mm/min

Cutting Accuracy:+/-0.1 mm

|

3300*1700*1180 mm

|

Can be Set Freely from 0.1 to 9999.9 mm

|

1050kg

|

|

MTF-1200 CT

|

|

1180 MM

|

|

4600*1940*1200mm

|

|

1500kg

|

|

MTF-1400 CT

|

|

1380 MM

|

|

4600*2140*1200mm

|

|

1950kg

|

|

MTF-1600 CT

|

|

1580 MM

|

|

4600*2340*1200mm

|

|

2300kg

|

|

MTF-1800 CT

|

|

1780 MM

|

|

4600*2540*1200mm

|

|

2750kg

|

Simple Operation Panel-Support Chinese and English

1) All digital buttons, easy to operate

2) LCD screen, intuitive and convenient

3) Freely set length, speed, batch, total

Vacuum Heat Treated Steel Knife

1) High-quality SKD-11 high-speed steel knife, sharp blade, wear-resistant and durable

2) Ensure that the incision is smooth and free of burrs

Speed Controller

1) Knob speed control, adjustable at any time, simple and convenient

2) AC speed regulating motor, stable performance

Air Shaft with Magnetic Brake

Prevent the inertial stretching of raw material roll from causing waste material

Multiple Correction Device

Multiple material rod/roller structure to achieve automatic correction effect, prevent material deviation, and ensure the squareness of the cut product without deviation

Static Electricity Removal device

Material friction will generate static electricity, add static rods to remove static electricity, keep the feeding process smooth, prevent material blocking, and ensure accurate cutting

OTHER CUSTOMIZED DEVICES

The machine is equipped with

an electronic eye tracking device

to effectively identify materials and accurately cut

.

The machine is equipped with

a

Utility knife

slitting device

to realize vertical slitting

The machine is equipped with

a Round knife slitting device

to realize vertical slitting

RECEIVING PLATE

The desktop cutting machine can be equipped with a receiving tray, and its length and width can be customized, ensure the neat feeling of the material

CONVEYOR BELT

The integrated cutting machine and large cutting machine can choose to install a conveyor belt, you can set the number of cutting times, and the conveyor belt forwards once

SUITABLE CUTTING MATERIAL

Bubble film, PVC plastic film, pet film, pe heat shrink film, reflective film, EVA, pearl film, sole film, bubble cushion, non-woven fabric, non-woven fabric, conductive cloth, acetate cloth, insulating paper, release paper, barley paper , Self-adhesive paper, bronzing paper, copper and aluminum foil and other materials

PRODUCT PHOTOS WITH PLANT BACKGROUND

SHIPPING WAY

1. Is it easy to operate?

Is it easy to learn. All digital keys, easy to operate,we have teaching video for customer.

2. Is the incision smooth, will loose edge, black edge?

Ultrasonic cutting without loose edge, rough edge and black edge, the cutting effect is good, especially suitable for cutting some high-end products.

4. Can I cut many shapes? (dovetail, fillet, bevel)

Yes, you can cut various shapes and customize the mold. The production cycle is about 7 working days.

5. Can the length be adjusted?

The length can be set freely, and the touch screen operation is very convenient.

6. How many discs can be cut at the same time?

According to the width of the material, generally 2.5cm wide material can be cut three rolls at the same time.

7. What is the error range?

No elastic material, no error, two thousandth of the theoretical error range.

8. How long can it last?

Can continue to work for 24 hours, pay attention to ventilation and reduce heat.

9. Is there a counting function?

You can set the total number and batch number at will.

10. How many meters can you cut in an hour?

High speed ultrasonic belt pulling machine can cut about 30-150 meters per minute.

11. Does the price include tax?

Online prices do not include tax, large equipment is not inclusive of freight.

12. How long is the warranty? Is the machine out of order?

One year warranty, lifelong after-sales service (except for mold, roller and other wearing parts).

2. Is the incision smooth, will loose edge, black edge?

Ultrasonic cutting without loose edge, rough edge and black edge, the cutting effect is good, especially suitable for cutting some high-end products.

3. Can ultrasound affect the human body?

It won't have any effect and can be used safely.

It won't have any effect and can be used safely.

4. Can I cut many shapes? (dovetail, fillet, bevel)

Yes, you can cut various shapes and customize the mold. The production cycle is about 7 working days.

5. Can the length be adjusted?

The length can be set freely, and the touch screen operation is very convenient.

6. How many discs can be cut at the same time?

According to the width of the material, generally 2.5cm wide material can be cut three rolls at the same time.

7. What is the error range?

No elastic material, no error, two thousandth of the theoretical error range.

8. How long can it last?

Can continue to work for 24 hours, pay attention to ventilation and reduce heat.

9. Is there a counting function?

You can set the total number and batch number at will.

10. How many meters can you cut in an hour?

High speed ultrasonic belt pulling machine can cut about 30-150 meters per minute.

11. Does the price include tax?

Online prices do not include tax, large equipment is not inclusive of freight.

12. How long is the warranty? Is the machine out of order?

One year warranty, lifelong after-sales service (except for mold, roller and other wearing parts).

Hot Searches