- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Year:

-

2021

-

Brand Name:

-

U Tech

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight (KG):

-

2500

-

Name:

-

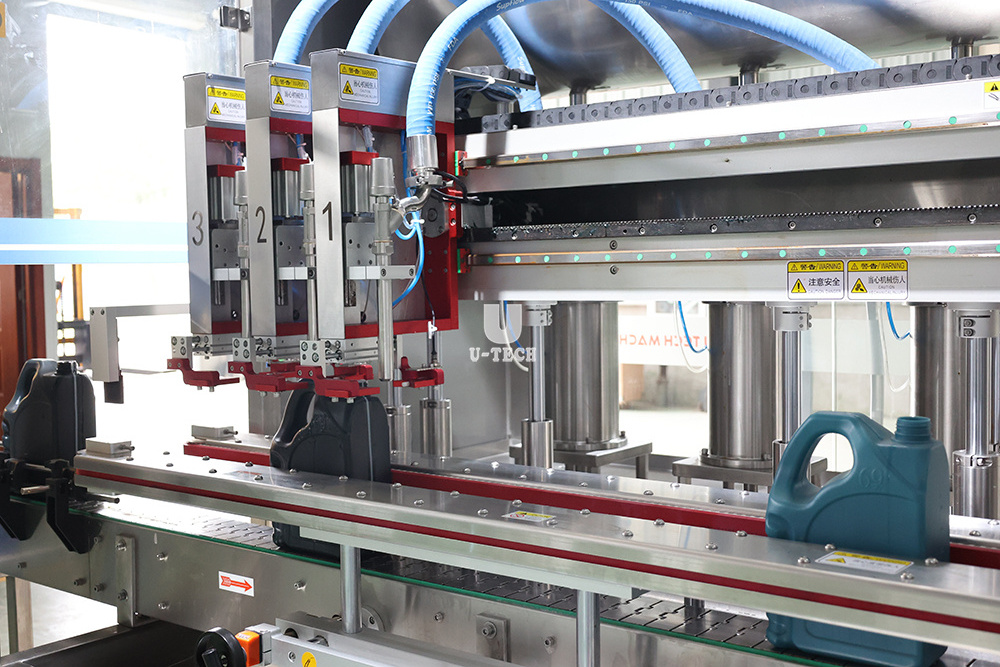

Lubricant Oil Filling Machine

-

Model:

-

UT-3

-

Capacity:

-

2000BPH

-

Filling range:

-

1-20L

-

Type:

-

Filling Machine

-

Application:

-

Commodity

-

Machinery Capacity:

-

2000BPH

-

Keywords:

-

Fillng Machine

-

Material:

-

SUS304/316

-

Advantage:

-

Efficiency

Quick Details

-

Production Capacity:

-

2000bph

-

Automatic Grade:

-

Automatic

-

Driven Type:

-

electric

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Year:

-

2021

-

Brand Name:

-

U Tech

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight (KG):

-

2500

-

Name:

-

Lubricant Oil Filling Machine

-

Model:

-

UT-3

-

Capacity:

-

2000BPH

-

Filling range:

-

1-20L

-

Type:

-

Filling Machine

-

Application:

-

Commodity

-

Machinery Capacity:

-

2000BPH

-

Keywords:

-

Fillng Machine

-

Material:

-

SUS304/316

-

Advantage:

-

Efficiency

Description and Flow

1L 4L 5L Automatic Lubriate Oil filling line

10L 20L Drum oil filling line

This type of automatic hand gel filling and capping machine can be used for fixed amount small package fling,straight line type flling, metical, electric,apparatus control of all sorts of viscous and no viscous erosive liquid,such as plant oil chemical,liquid,daily chemical industry.it is rather simple and rapid to change items,the design is quite distincthe property is Very advantageous,its appearance corresponds to international concept for mechanical equipment.

U TECH Machine is manufacturer and suppliers in China,and specialized in providing you with automatic hand gel filling and capping machine,hand washing fling machine and so on. hand gel filling and capping machine with stable performance, convenient operation, high cost performance.

Features

1. Contact part material : SS 316 , other machine parts : SS 304.

2. Suitable material: Oil, jams, daily chemicals, and something that very viscous.

3. This automatic hand gel filling and capping machine is a high-tech fling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

4. Accurate measurement: adopt servo control system, ensure the piston can always reaches constant position.

5. When close to target fling capacity can be applied to realize speed slow fling, prevent the liquid spill bottle mouth cause pollution.

2. Suitable material: Oil, jams, daily chemicals, and something that very viscous.

3. This automatic hand gel filling and capping machine is a high-tech fling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

4. Accurate measurement: adopt servo control system, ensure the piston can always reaches constant position.

5. When close to target fling capacity can be applied to realize speed slow fling, prevent the liquid spill bottle mouth cause pollution.

Technical Parameters

|

Model

|

UT-4

|

|

Forming and sealing speed

|

10ctns/min

|

|

Carton storage quantity

|

200pcs (1000mm)

|

|

Carton size

|

L200-450×W150-400×H100-400mm

|

|

Power supply

|

110/220V, 50/60Hz, 1 Phase

|

|

Power

|

200W

|

|

Applicable tape

|

48/60/75mm (Choose one type)

|

|

Machine size

|

L2000×W1900×H1450mm

|

|

Machine weight

|

450kg

|

Machine Details

Laser printer

Laser marking machines handle nearly every industrial marking and DPM (Direct Part Marking) task. Metals, plastics, ceramics, glass etc. are processed efficiently and contact-free. All desired contents are applied repeatedly accurate and reliably: 2D, DMC and alphanumeric codes, simple serial numbers, complex logos, graphics, structures. Depending on the material and application task, the process is laser marking, engraving or deep engraving.

Double face adhesive labeling machine

BST—100L Intellectual Labeling Machine is controlled by the PLC, HMI and servo drive labeling. The machine is easy to operate and has helping function and fault indication function. It is suitable for the self-adhesive labeling of round bottles.

Extrusion blow molding machine making 1-20L jerrycan

Injection molding machine making plastic caps

Recommend Products

About U TECH

Certificate

FAQ

Q1:Do you have any reference project?

>>

A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>>

A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>>

A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>>

A5:We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines.

Hot Searches