Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Kedah, Malaysia

-

Brand Name:

-

KIJ Excellence Titanium

-

Model Number:

-

TiN

-

Product Name:

-

PVD Hard Coating

-

Color:

-

gold

-

Type:

-

Titanium Nitride

-

Application:

-

Precision Equipment

-

Certificate:

-

ISO9001 ISO14001

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

TiN

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Kedah, Malaysia

-

Brand Name:

-

KIJ Excellence Titanium

-

Model Number:

-

TiN

-

Product Name:

-

PVD Hard Coating

-

Color:

-

gold

-

Type:

-

Titanium Nitride

-

Application:

-

Precision Equipment

-

Certificate:

-

ISO9001 ISO14001

|

Product Name

|

PVD Hard Coating / Titanium Nitride / TiN

|

|

Model

|

TiN

|

|

Introduction

|

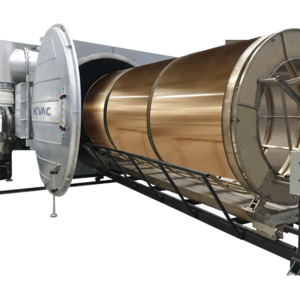

PVD hard coating is one of the best methods for optimising the hardness to residual compressive stress ratio. It uses a similar vacuum deposition coating method as the standard PVD coating that coats the product with a film of hard refractory material 2-7 microns thick.

|

|

Application

|

Hard Tool, Cutting Tools, Moulds, Drills, Endmills, Precision Components, Tools Refurbishment

|

|

Features

|

Appearance - excellent layer uniformity, Protection of polished and structured tool surface, Improvement in quality, Economical, Environmentally Friendly, Safety

|

About us

KIJ Excellence Titanium Sdn. Bhd., formerly known as Kristal Juta Sdn. Bhd. was founded in 1998 and was the first Physical Vapor Deposition (PVD) coating company in Malaysia.

Our company are specializes in:

* PVD Hard Coating

* Nano Coating Anti Finger Print (AFP) – Matte, Clear, Antique

* Surface Finishing – Glassbite (GB), Hairline (HL), 4B Hairline (4B), Checked Pattern (CP), Non Direction (ND), Mirror (M)

* Art of Stainless Steel

* Cosmetic Refurbishment of used parts

* Ultrasonic Cleaning

* Chrome Plating, Gold Plating, Copper Plating

* Selling PVD Equipment

* PVD Machine leak test and providing technical support service

Our PVD coating uses the vacuum deposition method which can be used to coat a range of materials, such as stainless steel, aluminium, iron, porcelain, tool steel, carbine and certain types of PVC. We use both multi arc and magnetron sputtering technology in our PVD coating process. Our facilities are able to fit products of up to 5ft in width and 20ft in height.

We are passionate and proactive in researching and developing more PVD coating colours in order to let our clients have more options to choose from. We are currently able to offer a wide range of PVD coating colours including Gold, Champagne, Nickel silver, Bronze, Copper, Brass, Black, Rose Gold, Dark Bronze (Coffee), Red Wine, Rainbow, Blue, Green, and Purple.

For the PVD Hard Coating, we are able to offer TiN, TiC TiCN, AlTiN or TiAlN, CrN, AlCrN and CrAlTiN coatings.

We currently have a team of 30 people, all of whom are highly trained and experienced. We have been appointed on many occasions to provide PVD coating services to many world famous brands and projects. Our client base is truly international and derives from a wide range of industrial sectors such as automotive manufacturers, construction companies, interior designers, shipping companies, electronic & electrical fabricators, medical companies and tools makers.

We aim to provide innovative and creative solutions for our clients, alongside an excellent quality of services. We are proud to be your helping hands in adding value to your products.

What We Do

Our PVD coating includes titanium coating, titanium aluminium coating and chromium coating. Our PVD coating uses the vacuum deposition method which can be used to coat a range of materials, such as stainless steel, aluminium, iron, porcelain, tool steel, carbide and certain types of PVC. We use both multi arc and magnetron sputtering technologies in our PVD coating processes.

Our facilities are able to fit products of up to 5ft in width and 20ft in height. We are passionate and proactive in researching and developing more PVD coating colours in order to let our clients have more options to choose from. We are currently able to offer a wide range of PVD coating colours including Gold, Champagne, Nickel Silver, Bronze, Copper, Brass, Black, Rose Gold, Dark Bronze(Coffee), Red wine, Rainbow, Blue, Green and Purple.

For the PVD Hard Coating, we are able to offer TiN, TiC, TiCN, AlTiN or TiAIN, CrN, AlCrN and CrAlTiN.

Accessories

Cosmetic Refurbishment

Logo and Signs

Featured Project