- Product Details

- {{item.text}}

Quick Details

-

Power:

-

10.5kw

-

Dimension(L*W*H):

-

1210X250X230

-

Weight:

-

4500

-

Product name:

-

wet wipes making machine

-

Wetting system:

-

Automatic Wetting Liquid

-

Type:

-

30~120 Pcs/pack

-

Function:

-

Folding-wetting-cutting-counting-output

-

Wet wipe machine:

-

High Speed Wet Tissue Machine

-

Wet wipes making machine:

-

High Speed Production Line

-

Suitable Raw Material:

-

Hot-rolling Non-woven Fabric

-

Application:

-

Wet Wipe Pouch Lid Application

-

Folding way:

-

4 Folding Horizontal

-

Keyword:

-

Alcohol Wipes Packing Machine

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

AD

-

Voltage:

-

220v 50/60Hz

-

Power:

-

10.5kw

-

Dimension(L*W*H):

-

1210X250X230

-

Weight:

-

4500

-

Product name:

-

wet wipes making machine

-

Wetting system:

-

Automatic Wetting Liquid

-

Type:

-

30~120 Pcs/pack

-

Function:

-

Folding-wetting-cutting-counting-output

-

Wet wipe machine:

-

High Speed Wet Tissue Machine

-

Wet wipes making machine:

-

High Speed Production Line

-

Suitable Raw Material:

-

Hot-rolling Non-woven Fabric

-

Application:

-

Wet Wipe Pouch Lid Application

-

Folding way:

-

4 Folding Horizontal

-

Keyword:

-

Alcohol Wipes Packing Machine

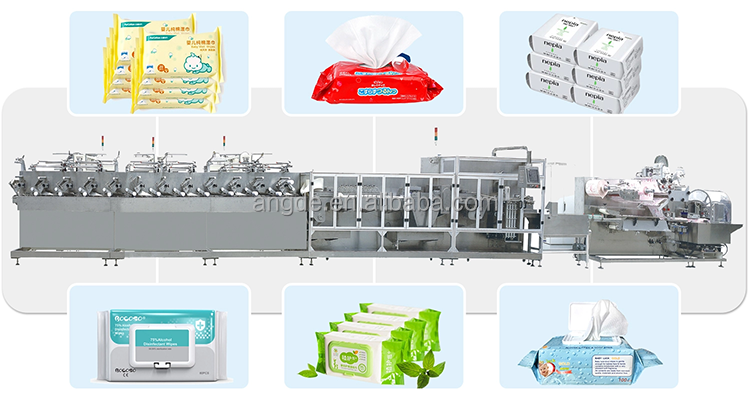

Fully Automatic Wet wipe machine /production line for baby wet wipe

Product Description

Equipment performance and characteristics:

1. Range of use: 30-80 pieces/bag. Baby wipes, industrial wipes, kitchen wipes, household wipes, etc.

2. Working principle: (1 roll material loading → online slitting → automatic folding → automatic liquid addition → automatic cutting → automatic stacking → automatic counting) → wet wipes waiting. Material conveying → (into the packaging machine → roll film placement Roll → print production date → punch → label → bag making → back seal → pin horizontal seal) → finished product output, the whole line is completed automatically.

3. The equipment is equipped with a set of 1250mm slitting machine, which can cut large rolls into the desired width of wet wipes, and can cut up to 6 wet wipes.

4. The equipment is equipped with 6 sets of folding devices, which can fold N, V, and C types; the equipment is equipped with servo fixed-length cutting and servo automatic stacking, which can be set freely on the touch screen.

5. Track: Realize the specific speed connection between the folding machine and the packaging machine.

6.450 type reciprocating packaging machine consists of: reciprocating packaging machine + coding machine + punch labeling machine;

7. Coding machine: It uses ink wheel to code, and the coding position is controlled by an independent servo motor, which can be selected on the touch screen.

8. Punching labeling machine: It is composed of a punching machine combined with a labeling machine, both of which are driven by an independent servo motor, which can be selected on the touch screen.

9. Reciprocating packaging machine: the width and height of the bag forming machine can be adjusted according to actual requirements; the horizontal sealing pin mechanism is composed of reciprocating pin holders; the back seal and horizontal seal are composed of independent PIDs, and the temperature can be freely adjusted according to actual production needs. Control on the touch screen.

10. The equipment adopts imported PLC program control system, computer touch screen display, frequency conversion, and joint control; the wiring specifications of the electrical parts are reasonable, beautiful, elegant, and easy to operate.

The steel frame of the whole machine is welded by high-quality 45# channel steel of the national standard, and the surface is treated with anti-rust spray paint. The electrical appliances are all made of China. The standard parts such as screws and nuts are all made of national standard consumables, which may easily affect the finished product. The screws are made of stainless steel, the whole machine has a compact structure, stable high-speed operation, stable performance, simple operation, beautiful

appearance, and stable operation. It is the best choice for the production of non-woven wet wipes!

appearance, and stable operation. It is the best choice for the production of non-woven wet wipes!

Specification

|

Production speed

|

6-15 bags/min

|

|

Voltage/frequency/total power

|

380V+220V/50Hz/10.5kw

|

|

Size of wet wipes

|

length≤200mm; width≤120mm; height:≤55mm

|

|

Packing bag size

|

length≤430mm; width≤120mm; height:≤60mm

|

|

Film roll material

|

OPP; PET+PE; composite film

|

|

Film roll widt

|

≤450mm;

|

|

Folding machine: overall dimensions

|

6800mm × 1000mm × 2200mm

|

|

Track: Overall dimensions

|

3000mm ×350mm ×1100mm

|

|

Packing machine: Dimensions

|

2300mm×1000mm× 2300mm

|

|

Equipment weight

|

4500kg

|

Packing & Delivery

1.Packed by standard import & export wooden cases or carton boxes.

2. Shipping:Courier service,Air transport,Sea Transport

2. Shipping:Courier service,Air transport,Sea Transport

Hot Searches