- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V/50HZ

-

Product Type:

-

Industrial Machinery

-

Laser Power:

-

1500W/3000W/6000W/12000W (Optional)

-

Working Area:

-

3*1.5M/4*1.5M/6*1.5M/6*2M (Optional)

-

Cutting Materials:

-

Stainless Steel Coil/Iron Coil/Galvanized Coil/Copper Coil

-

Cutting Thickness:

-

0.2MM-6MM (Optional, Also Support Thick Plate)

-

Maxi. Load Bearing Capacity:

-

5T-20T (Optional)

-

Maxi. Linkage Speed:

-

120M/MIN

-

Repositioning Accuracy:

-

±0.02MM

-

Maxi. Acceleration:

-

1.2G

-

Certification:

-

GB/T19001-2016/ISO9001:2015

-

After-sales Service:

-

One Year Free Warranty, Lifetime Paid Maintenance

Quick Details

-

Machinery Capacity:

-

100 Sets/1 Year

-

Brand Name:

-

Hcgmt

-

Year:

-

2024

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V/50HZ

-

Product Type:

-

Industrial Machinery

-

Laser Power:

-

1500W/3000W/6000W/12000W (Optional)

-

Working Area:

-

3*1.5M/4*1.5M/6*1.5M/6*2M (Optional)

-

Cutting Materials:

-

Stainless Steel Coil/Iron Coil/Galvanized Coil/Copper Coil

-

Cutting Thickness:

-

0.2MM-6MM (Optional, Also Support Thick Plate)

-

Maxi. Load Bearing Capacity:

-

5T-20T (Optional)

-

Maxi. Linkage Speed:

-

120M/MIN

-

Repositioning Accuracy:

-

±0.02MM

-

Maxi. Acceleration:

-

1.2G

-

Certification:

-

GB/T19001-2016/ISO9001:2015

-

After-sales Service:

-

One Year Free Warranty, Lifetime Paid Maintenance

Product Description

|

Configurations &

Parameters

|

|

|

|

Product Name

|

Leveling Geared Feeding Fiber Laser Cutting Collection Station Product Line

|

|

|

Working Area

|

3*1.5M/4*1.5M/6*1.5M/6*2M(Customizable)

|

|

|

Laser Power

|

1500W/3000W/6000W/12000W(Optional)

|

|

|

Cutting Thickness

|

1.5MM/2MM/3MM/4MM (Optional)

|

|

|

Maxi. Load Bearing Capacity

|

5T-20T (Optional)

|

|

|

Leveling Roller

|

13/15/17/19 (Optional)

|

|

|

Leveling Stick Diameter

|

100MM/120MM/150MM (Optional)

|

|

|

Positioning Accuracy

|

±0.05MM

|

|

|

Repositioning Accuracy

|

±0.02MM

|

|

|

Maxi. Linkage Speed

|

120M/MIN

|

|

|

Maxi.Traverse Speed

|

60M/MIN

|

|

|

Maxi. Acceleration

|

1.2G

|

|

|

Cooling Type

|

Water Cooling

|

|

|

Cooling Water

|

Purified Water/Deionized Water/Distilled Water(Optional)

|

|

|

Air Supply Pressure

|

Dried And Filtered Air: 1Mpa-1.3Mpa

|

|

|

|

Nitrogen: 0.8Mpa-1.2Mpa

|

|

|

|

Oxygen: 0.4Mpa-0.8Mpa

|

|

|

Graphic Format Supported

|

AI/DXF/DWG/EPS/PLT/SVG

|

|

|

Phases

|

Three-Phase Current

|

|

|

Working Voltage

|

380V/50HZ

|

|

|

Working Temperature

|

5℃-35℃

|

|

|

Power Protection Level

|

IP54

|

|

|

Laser Type

|

Fiber Laser

|

|

|

Laser Wavelength

|

1060nm-1080nm

|

|

|

Laser Beam Quality

|

<0.373Mrad

|

|

|

Laser Cutting Operating System

|

Cypcut 2000C/2000E/6000/8000C(China)(Optional)

|

|

|

Laser Generator

|

Max(China)

|

|

|

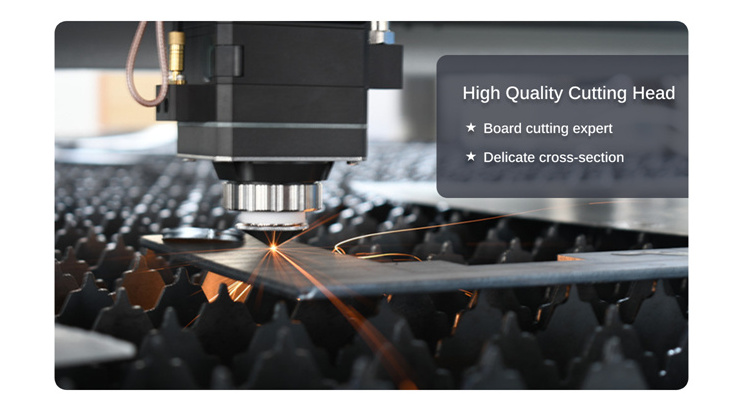

Laser Head

|

WSX(China)

|

|

|

Laser Optical Lens

|

WSX(China)

|

|

|

Servo Motor

|

Delta(Taiwan, China)

|

|

|

Industrial Chiller

|

Han Li(China)

|

|

|

Reducer

|

Beitto(Japan)/Shimpo(Japan)(Optional)

|

|

|

Proportional Valve

|

SMC(Japan)

|

|

|

X Y Axis Linear Guide Rails

|

HSAC(Taiwan, China)

|

|

|

Electrical Cabinet

|

Schneider(France)

|

|

|

Axis

|

Horizontal X Axis

|

|

|

|

Vertical Y Axis

|

|

|

|

Up-And-Down Z Axis

|

|

|

Machine Tool Bed

|

Carbon Steel Machine Tool Bed

|

|

|

|

Aeronautical Aluminum Crossbeam

|

|

|

|

Sheet Metal Welded Box Frame

|

|

|

|

Double Tempering

|

|

|

Cutting Materials

|

Iron Coil

|

|

|

|

Stainless Steel Coil

|

|

|

|

Galvanized Steel Coil

|

|

|

|

Aluminum Alloy Coil

|

|

|

|

Copper Coil

|

|

|

Certifications

|

(EU) 2023/1230

|

|

|

|

FCC PART 18

|

|

|

|

ISO9001:2015

|

|

|

After-sales Service

|

One Year Free Warranty, Lifetime Paid Maintenance

|

|

|

Air Compressor

|

Optional Configuration

|

|

|

Voltage Stabilizer

|

Optional Configuration

|

|

|

Dust Collector

|

Optional Configuration

|

|

|

Automatic Loading And Unloading

|

Optional Configuration

|

|

|

Notice: All Parameters And Accessories Are Dynamic and For Reference Only. For More Information, Please Contact Online Customer Service.

|

|

|

Product Display

Finished Cut

Cutting Parameters

|

Stainless Steel Plate (SUS 304)

Cutting Speed (M/MIN)

|

|

|

|

|

|

|

|

|||||||

|

Thickness

|

Gas

|

1500W

|

3000W

|

6000W

|

12000W

|

15000W

|

20000W

|

|||||||

|

1MM

|

Nitrogen/Oxygen

|

27-30

|

50-53

|

59-65

|

/

|

/

|

/

|

|||||||

|

2MM

|

Nitrogen/Oxygen

|

8.0-9.0

|

23-25

|

32-38

|

/

|

/

|

/

|

|||||||

|

3MM

|

Nitrogen/Oxygen

|

4.2-4.5

|

10-12

|

20-24

|

32-38

|

34-39

|

35-40

|

|||||||

|

4MM

|

Nitrogen/Oxygen

|

2.0-2.2

|

6.0-8.0

|

12-15

|

22-26

|

25-29

|

28-32

|

|||||||

|

5MM

|

Nitrogen/Oxygen

|

1.5-1.7

|

/

|

9.0-11

|

17-20

|

18-22

|

25-28

|

|||||||

|

6MM

|

Air

|

/

|

2.9-3.1

|

6.0-7.5

|

14-16

|

17-20

|

/

|

|||||||

|

|

Nitrogen

|

/

|

2.9-3.1

|

6.0-7.5

|

13-15

|

16-19

|

20-24

|

|||||||

|

8MM

|

Air

|

/

|

1.2-1.3

|

4.0-4.5

|

10-12

|

12-14

|

/

|

|||||||

|

|

Nitrogen

|

/

|

1.2-1.3

|

4.0-4.5

|

9.0-11

|

11-13

|

14-16

|

|||||||

|

10MM

|

Air

|

/

|

0.75-0.8

|

2.2-2.4

|

8.0-9.0

|

8.0-10

|

/

|

|||||||

|

|

Nitrogen

|

/

|

0.75-0.8

|

2.2-2.4

|

7.5-8.0

|

7.0-9.0

|

11-13

|

|||||||

|

12MM

|

Air

|

/

|

0.5

|

1.3-1.5

|

6.0-6.5

|

7.0-7.5

|

/

|

|||||||

|

|

Nitrogen

|

/

|

0.5

|

1.3-1.5

|

5.2-6.0

|

6.0-6.5

|

8.0-10

|

|||||||

|

14MM

|

Air

|

/

|

/

|

0.9-1.0

|

3.7-4.0

|

4.8-5.0

|

/

|

|||||||

|

|

Nitrogen

|

/

|

/

|

0.9-1.0

|

3.2-3.5

|

4.3-4.5

|

6.5-7.0

|

|||||||

|

16MM

|

Air

|

/

|

/

|

/

|

2.7-3.0

|

3.4-3.8

|

/

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

2.3-2.5

|

3.0-3.5

|

4.5-5.5

|

|||||||

|

18MM

|

Air

|

/

|

/

|

/

|

2.2-2.5

|

3.0-3.3

|

/

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

1.8-2.0

|

2.6-2.8

|

3.5-4.5

|

|||||||

|

20MM

|

Air

|

/

|

/

|

/

|

1.6-1.8

|

2.0-2.2

|

/

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

1.3-1.5

|

1.6-1.8

|

2.3-2.6

|

|||||||

|

25MM

|

Air

|

/

|

/

|

/

|

0.8-1.0

|

1.2-1.5

|

/

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

0.7-0.8

|

1.1-1.3

|

1.8-2.2

|

|||||||

|

30MM

|

Air

|

/

|

/

|

/

|

/

|

0.6-0.7

|

/

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

/

|

0.33-0.35

|

0.8-1.3

|

|||||||

|

35MM

|

Nitrogen

|

/

|

/

|

/

|

/

|

/

|

0.3-0.6

|

|||||||

|

Notice: All Parameters Are Dynamic And For Reference Only. For More Information, Please Contact Customer Service.

|

|

|

|

|

|

|

|

|||||||

|

Carbon Steel Plate (Q235B) Cutting Speed (M/MIN)

|

|

|

|

|

|

|

|

|||||||

|

Thickness

|

Gas

|

1500W

|

3000W

|

6000W

|

12000W

|

15000W

|

20000W

|

|||||||

|

1MM

|

Nitrogen/Air

|

26-29

|

47-50

|

58-62

|

/

|

/

|

/

|

|||||||

|

2MM

|

Nitrogen/Air

|

7.0-8.0

|

21-23

|

31-36

|

/

|

/

|

/

|

|||||||

|

3MM

|

Nitrogen/Air

|

/

|

6.0-12

|

18-22

|

32-38

|

34-39

|

35-40

|

|||||||

|

|

Oxygen

|

2.9-3.2

|

3.9-4.1

|

/

|

/

|

/

|

/

|

|||||||

|

4MM

|

Nitrogen/Air

|

/

|

/

|

11-13

|

22-26

|

25-29

|

26-30

|

|||||||

|

|

Oxygen

|

2.4-2.6

|

3.4-3.6

|

3.7-4.0

|

/

|

/

|

/

|

|||||||

|

5MM

|

Nitrogen/Air

|

/

|

/

|

8.0-10

|

17-20

|

18-22

|

25-28

|

|||||||

|

|

Oxygen

|

1.8-2.0

|

/

|

3.2-3.3

|

/

|

/

|

/

|

|||||||

|

6MM

|

Air

|

/

|

/

|

5.5-6.5

|

12-14

|

16-18

|

22-24

|

|||||||

|

|

Nitrogen

|

/

|

/

|

5.5-6.5

|

11-13

|

15-17

|

/

|

|||||||

|

|

Oxygen

|

1.6-1.8

|

2.7-2.8

|

2.6-2.8

|

2.6-2.8

|

2.6-2.8

|

2.5-3.0

|

|||||||

|

8MM

|

Air

|

/

|

/

|

/

|

8.0-10

|

10-11

|

13-15

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

7.0-9.0

|

9.0-10

|

/

|

|||||||

|

|

Oxygen

|

1.1-1.3

|

2.1-2.3

|

2.5-2.6

|

2.5-2.6

|

2.5-2.6

|

2.3-2.8

|

|||||||

|

10MM

|

Air

|

/

|

/

|

/

|

5.0-6.0

|

7.0-8.0

|

10-12

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

4.5-5.5

|

6.5-7.0

|

/

|

|||||||

|

|

Oxygen

|

0.9-1.0

|

1.4-1.6

|

2.2-2.3

|

2.2-2.3

|

2.2-2.3

|

2.2-2.6

|

|||||||

|

12MM

|

Air

|

/

|

/

|

/

|

4.2-5.0

|

5.5-6.5

|

8.0-9.0

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

4.0-4.8

|

5.0-6.0

|

/

|

|||||||

|

|

Oxygen

|

0.8-0.9

|

1.0-1.1

|

1.8-2.0

|

1.9-2.0

|

1.9-2.0

|

2.0-2.2

|

|||||||

|

14MM

|

Air

|

/

|

/

|

/

|

3.5-4.2

|

5.0-5.55

|

5.5-6.5

|

|||||||

|

|

Nitrogen

|

/

|

/

|

/

|

3.2-3.5

|

4.8~5.0

|

/

|

|||||||

|

|

Oxygen

|

/

|

0.9-0.95

|

1.4-1.7

|

1.5-1.6

|

1.5-1.6

|

1.8-2.0

|

|||||||

|

16MM

|

Air

|

/

|

/

|

/

|

/

|

/

|

3.0-4.0

|

|||||||

|

|

Oxygen

|

/

|

0.8-0.95

|

1.2-1.3

|

1.4-1.6

|

1.4-1.6

|

1.6-1.8

|

|||||||

|

18MM

|

Air

|

/

|

/

|

/

|

/

|

/

|

3.0-3.5

|

|||||||

|

|

Oxygen

|

/

|

0.7-0.72

|

0.7-0.8

|

1.4-1.5

|

1.4-1.5

|

1.5-1.7

|

|||||||

|

20MM

|

Air

|

/

|

/

|

/

|

/

|

/

|

2.0-3.0

|

|||||||

|

|

Oxygen

|

/

|

/

|

0.6-0.65

|

1.4-1.5

|

1.4-1.5

|

1.4-1.6

|

|||||||

|

22MM

|

Oxygen

|

/

|

/

|

0.55-0.6

|

1.2

|

1.2-1.3

|

1.3-1.5

|

|||||||

|

25MM

|

Oxygen

|

/

|

/

|

/

|

1.0

|

1.2-1.3

|

1.2-1.4

|

|||||||

|

30MM

|

Oxygen

|

/

|

/

|

/

|

0.4

|

0.8~0.9

|

1.0-1.3

|

|||||||

|

35MM

|

Oxygen

|

/

|

/

|

/

|

0.35

|

0.4

|

0.9-1.2

|

|||||||

|

40MM

|

Oxygen

|

/

|

/

|

/

|

/

|

0.35

|

0.5-0.8

|

|||||||

|

45MM

|

Oxygen

|

|

|

/

|

/

|

/

|

/

|

|||||||

|

50MM

|

Oxygen

|

/

|

/

|

/

|

/

|

/

|

0.3-0.5

|

|||||||

|

Notice: All Parameters Are Dynamic And For Reference Only. For More Information, Please Contact Customer Service.

|

|

|

|

|

|

|

|

|||||||

|

Aluminum Plate

Cutting Speed (M/MIN)

|

|

|

|

|

|

|

|

|||||||

|

Thickness

|

Gas

|

1500W

|

3000W

|

6000W

|

12000W

|

15000W

|

20000W

|

|||||||

|

1MM

|

Nitrogen/Air

|

21-23

|

40-43

|

43-46

|

/

|

/

|

/

|

|||||||

|

2MM

|

Nitrogen/Air

|

5.0-7.0

|

16-18

|

26-28

|

/

|

/

|

/

|

|||||||

|

3MM

|

Nitrogen/Air

|

3.2-3.5

|

8.0-10

|

14-17

|

27-30

|

28-32

|

29-34

|

|||||||

|

4MM

|

Nitrogen/Air

|

1.5-1.7

|

5.0-6.0

|

10-11

|

19-21

|

20-22

|

21-26

|

|||||||

|

5MM

|

Nitrogen/Air

|

0.5-0.7

|

/

|

6.0-6.5

|

14-16

|

16-18

|

16-20

|

|||||||

|

6MM

|

Nitrogen/Air

|

/

|

1.5-2.0

|

4.5-5.0

|

10-12

|

12-14

|

13-17

|

|||||||

|

8MM

|

Nitrogen/Air

|

/

|

0.6-0.7

|

2.8-2.9

|

7.0-8.0

|

8.0-9.0

|

10-13

|

|||||||

|

10MM

|

Nitrogen/Air

|

/

|

/

|

1.7-1.8

|

4.0-4.5

|

5.5-6.0

|

6.0-8.0

|

|||||||

|

12MM

|

Nitrogen/Air

|

/

|

/

|

1.0-1.2

|

2.5-3.0

|

3.5-4.0

|

4.0-6.0

|

|||||||

|

14MM

|

Nitrogen/Air

|

/

|

/

|

0.7-0.9

|

2.3-2.5

|

2.5-3.0

|

3.0-4.0

|

|||||||

|

16MM

|

Nitrogen/Air

|

/

|

/

|

0.5-0.6

|

1.6-1.8

|

1.8-2.0

|

2.0-3.0

|

|||||||

|

18MM

|

Nitrogen/Air

|

/

|

/

|

/

|

1.0-1.2

|

1.4-1.6

|

1.5-2.0

|

|||||||

|

20MM

|

Nitrogen/Air

|

/

|

/

|

/

|

0.8

|

0.9-1.0

|

1.0-1.5

|

|||||||

|

22MM

|

Nitrogen/Air

|

/

|

/

|

/

|

0.5

|

0.8

|

/

|

|||||||

|

25MM

|

Nitrogen/Air

|

/

|

/

|

/

|

/

|

0.5

|

0.8-1.0

|

|||||||

|

30MM

|

Nitrogen/Air

|

/

|

/

|

/

|

/

|

/

|

0.5-0.8

|

|||||||

|

40MM

|

Nitrogen/Air

|

/

|

/

|

/

|

/

|

/

|

0.3-0.5

|

|||||||

|

50MM

|

Nitrogen/Air

|

/

|

/

|

/

|

/

|

/

|

0.2-0.3

|

|||||||

|

Notice: All Parameters Are Dynamic And For Reference Only. For More Information, Please Contact Customer Service.

|

|

|

|

|

|

|

|

|||||||

|

Copper Plate

Cutting Speed (M/MIN)

|

|

|

|

|

|

|

|

|||||||

|

Thickness

|

Gas

|

1500W

|

3000W

|

6000W

|

12000W

|

15000W

|

20000W

|

|||||||

|

1MM

|

Nitrogen/Air

|

18-20

|

37-40

|

41-43

|

/

|

/

|

/

|

|||||||

|

2MM

|

Nitrogen/Air

|

4.0-5.0

|

14-16

|

24-26

|

/

|

/

|

/

|

|||||||

|

3MM

|

Nitrogen/Air

|

2.3-2.5

|

7.0-9.0

|

13-14

|

25-28

|

25-29

|

28-30

|

|||||||

|

4MM

|

Nitrogen/Air

|

1.2-1.4

|

3.0-4.0

|

9.0-10

|

16-18

|

18-20

|

21-26

|

|||||||

|

5MM

|

Nitrogen/Air

|

/

|

/

|

5.0-6.0

|

12-14

|

13-16

|

14-18

|

|||||||

|

6MM

|

Nitrogen/Air

|

/

|

1.2-1.5

|

4.0-4.5

|

9.0-11

|

11-13

|

11-15

|

|||||||

|

8MM

|

Nitrogen/Air

|

/

|

0.5-0.6

|

2.3-2.5

|

6.0-7.0

|

7.0-8.0

|

8.0-10

|

|||||||

|

10MM

|

Nitrogen/Air

|

/

|

|

1.5-1.6

|

3.5-4.5

|

5.0-5.5

|

5.0-7.0

|

|||||||

|

12MM

|

Nitrogen/Air

|

/

|

|

1.0-1.2

|

2.2-2.8

|

3.2-3.5

|

4.0-6.0

|

|||||||

|

14MM

|

Nitrogen/Air

|

/

|

|

0.7-0.9

|

1.8-2.0

|

2.3-2.8

|

2.0-3.0

|

|||||||

|

16MM

|

Nitrogen/Air

|

/

|

|

0.5-0.6

|

1.4-1.6

|

1.5-1.8

|

1.8-2.5

|

|||||||

|

18MM

|

Nitrogen/Air

|

/

|

|

/

|

0.8-1.0

|

1.1-1.3

|

1.5-2.0

|

|||||||

|

20MM

|

Nitrogen/Air

|

/

|

|

/

|

0.7

|

0.7-0.9

|

/

|

|||||||

|

22MM

|

Nitrogen/Air

|

/

|

|

/

|

0.4

|

0.7

|

/

|

|||||||

|

25MM

|

Nitrogen/Air

|

/

|

|

/

|

/

|

0.4

|

/

|

|||||||

|

Notice: All Parameters Are Dynamic And For Reference Only. For More Information, Please Contact Customer Service.

|

|

|

|

|

|

|

|

|||||||

Hot Searches