- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TECHPRO EQUIPMENT LLC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1250*800*900

-

Weight (T):

-

1.2 T

-

Power (kW):

-

400-10000

-

After-sales Service Provided:

-

Overseas Installation & Training

-

Product Name:

-

500kg-15ton Industrial Electrical Induction Steel Iron Melting Furnace

-

Melting Material:

-

Scrap Steel Iron Copper Aluminum

-

Final product:

-

Rebar,wire Rod,steel Angel,steel Flat

-

Furnace Capacity:

-

50kg-30ton

-

Function:

-

Real-time Detection,leaking Alarm Device, Smelting Management System

-

MF Voltage:

-

750V,1200V,1700V

-

Melting speed:

-

<40min

-

Output DC current:

-

700A

-

Input Current:

-

560A

Quick Details

-

Place of Origin:

-

China

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

furnace body, electric cabinet

-

Brand Name:

-

TECHPRO EQUIPMENT LLC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1250*800*900

-

Weight (T):

-

1.2 T

-

Power (kW):

-

400-10000

-

After-sales Service Provided:

-

Overseas Installation & Training

-

Product Name:

-

500kg-15ton Industrial Electrical Induction Steel Iron Melting Furnace

-

Melting Material:

-

Scrap Steel Iron Copper Aluminum

-

Final product:

-

Rebar,wire Rod,steel Angel,steel Flat

-

Furnace Capacity:

-

50kg-30ton

-

Function:

-

Real-time Detection,leaking Alarm Device, Smelting Management System

-

MF Voltage:

-

750V,1200V,1700V

-

Melting speed:

-

<40min

-

Output DC current:

-

700A

-

Input Current:

-

560A

|

Welcome to TECHPRO EQUIPMENT LLC from USA. We are reputable supplier and Our customers are all over the world. |

We provide customers with overall plant design solutions for steel smelting, rolling, casting,insulation and anti-corrosion coating of steel pipes , heat treatment, and regeneration of waste metals such as steel, copper, aluminum, zinc and stainless steel. The main products include medium-frequency melting furnaces , medium-frequency induction heating furnaces , furnaces for recycling scrap steel, copper, and aluminum, zinc, stainless steel, etc. Also vacuum furnaces, steel refining, rolling equipment, open and closed cooling towers, medium and high-frequency surface quenching equipments, continuous casting machines , steel bar production lines and non-ferrous metal ingot production lines .

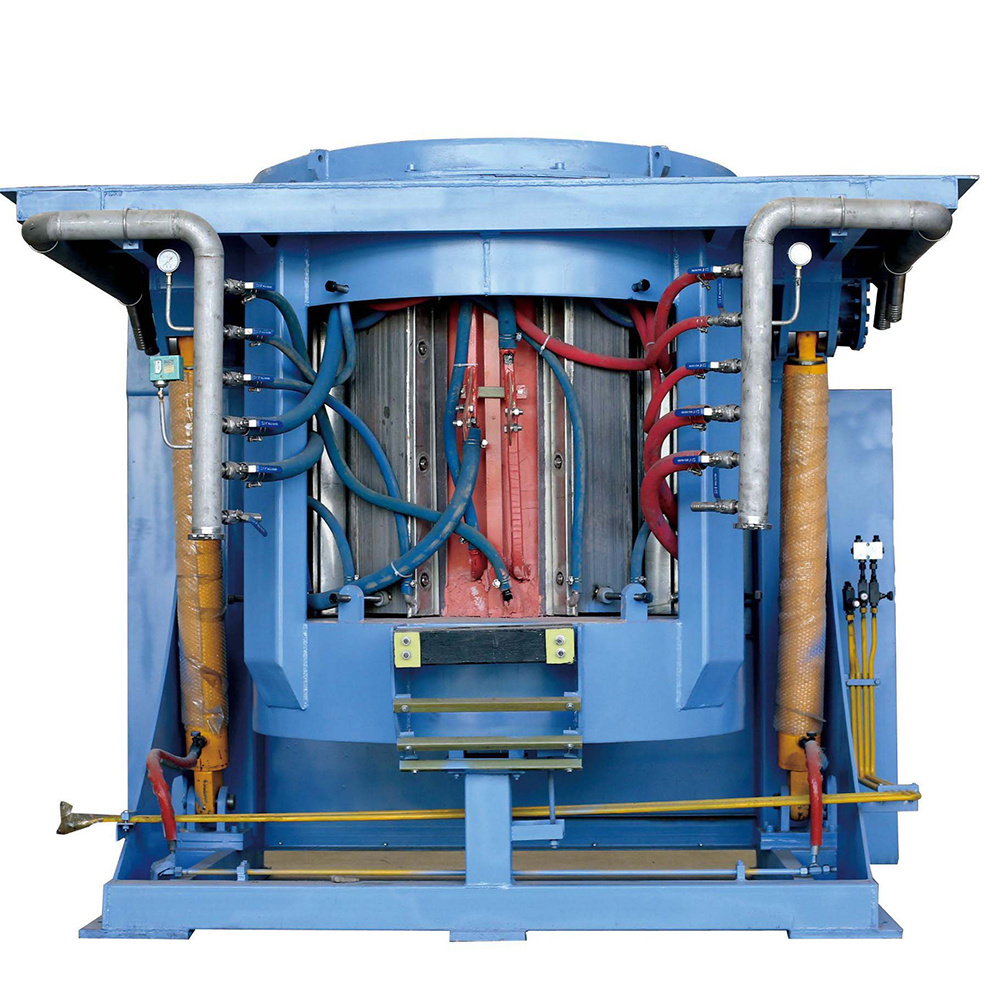

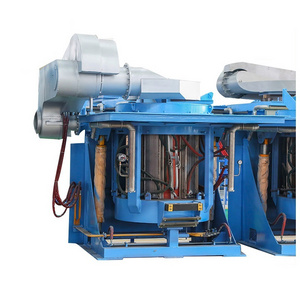

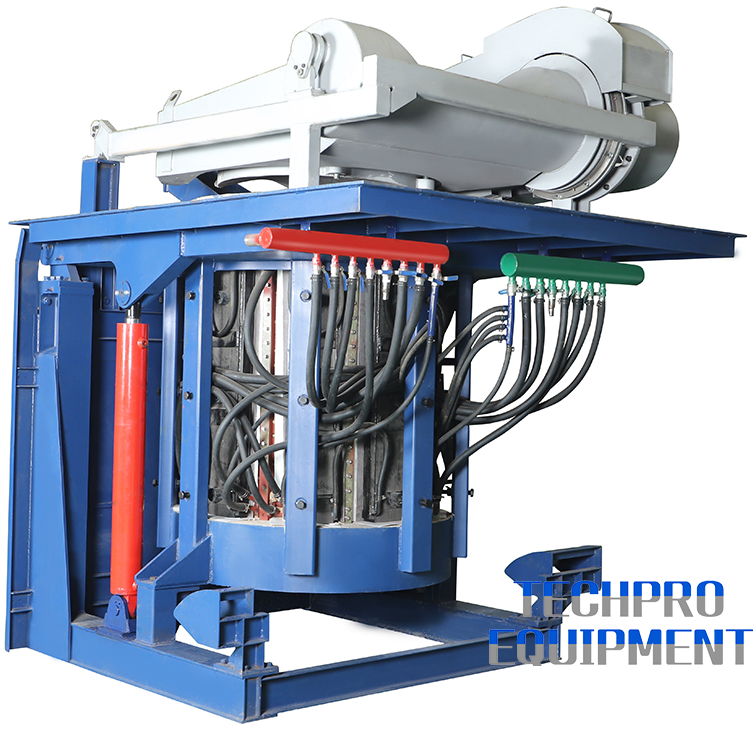

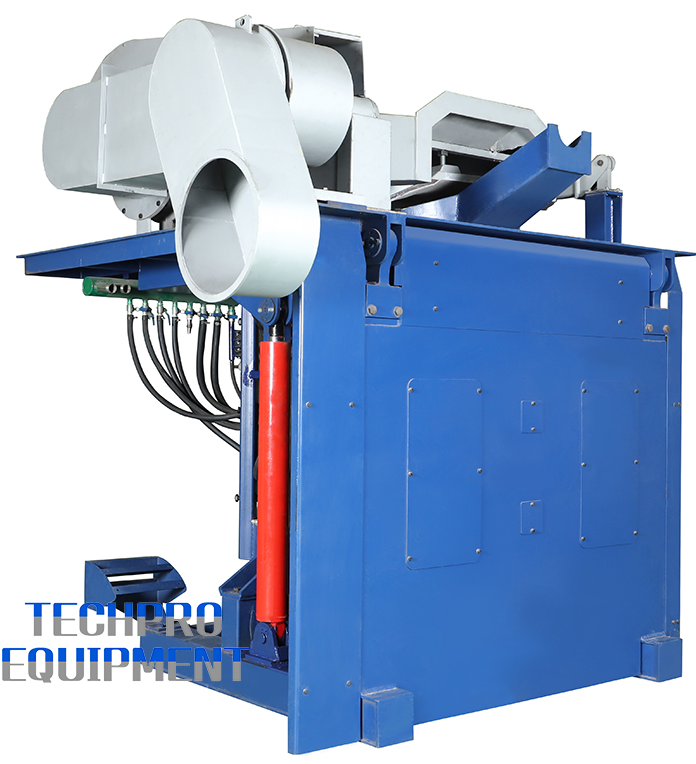

| Steel iron melting furnace steel shell |

|

|

Steel shell furnaces are suitable for big foundry,automatic foundry and precision casting foundry. Steel shell furnaces are more safe when required to more than 2 tons capaicty per hour. They have hydraulic station to control pouring angle and pouring speed.

This steel iron melting furnace is widely used in steel mill,foundry plant and other industries. It has the advantages of fast melting speed, high production efficiency, strong adaptability, flexible use, good electromagnetic stirring effect and convenient starting operation.

This type of induction melting furnace can melt scrap steel, iron, stainless steel, copper, aluminum and other metals scrap.

The furnace is mainly composed of power control cabinet and melting furnace body. The auxiliary equipments include transformer and closed cooling tower.

| Raw material | Melting | Final product |

| Safety Protection | TECHPRO EQUIPMENT LLC |

• Main circuit short circuit protection

• Main circuit phase loss protection

• Main circuit phase fault protection

• SCR over-current protection

• SCR overvoltage protection

• Cooling water temperature protection

• Low water pressure protection

• Furnace leakage protection

• Intermediate frequency power failure protection

• Intermediate frequency electric furnace fault protection rate and increase the life obviously

| Melting Furnace Features | TECHPRO EQUIPMENT LLC |

- Saving Features

Fast heating temperature, very little oxidation, oxidation frequency heating forging burning only 0.5%, gas furnace heating oxidation loss of 2%, 3% of coal-fired furnace, intermediate frequency heating technology and materials, each ton forgings and burning stove saves at least compared to 20-50 kg of steel materials. Its material utilization up to 95%.

Since the uniform heating, the temperature difference between the minimum core table, so in terms of forging also greatly increases the life of forging dies, forging surface roughness is less than 50um saving technology, frequency heating oil heating proportion of 31.5% ~ 54.3% energy saving, gas heating energy than 5% to 40%. Good heating quality, reduce scrap 1.5%, increase productivity by 10% to 30%, extend tool life by 10% to 15%.

- Environmental Features

Working environment is superior, to improve the working environment of workers and the corporate image, no pollution, low energy Induction furnace, workers will no longer be compared to the hot sun baked and smoked coal stove, but can reach the targets of environmental protection departments, while the external image of the company and establish a future as well as the forging industry trends.

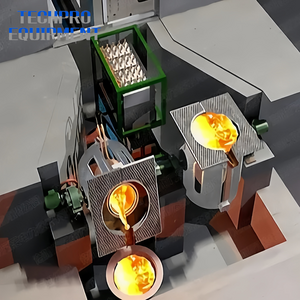

| Overseas Use Cases | TECHPRO EQUIPMENT LLC |

Most of our customers are new in metal casting industry. They make Ingots, steel rebar, iron powder, auto parts, bronze statues, iron pots or manhole covers, etc.

Most of our customers are from Africa and Asia, as well as some countries in Europe and south Afica. Such as Egypt, Algeria, Tanzania,South Africa, Zimbabwe, Saudi Arabia, Georgia,Uzbekistan, Kazakhstan, Malaysia, Indonesia, Vietuam, Bangladesh, Russia, Mecigo, Colombiaetc, Venezuela, etc.

Installation, debugging and final acceptance

1. After the equipments arrive at the site, our engineer will guide the installation according to the time notified by the customer. After the installation, the melting furnace and electric cabinet will be debugged.

2. Our engineer will provide on-site training to the customer's equipment operation and maintenance personnel on the operation and maintenance of the equipment.

3. The final acceptance of the equipment should be at the customer's site.

The acceptance items include:

(1) All factory inspection items and comprehensive safety inspections;

(2) Measurement of sensor power and heating productivity;

(3) Measurement of cooling medium temperature rise;

(4) Measurement of sensor component temperature;

(5) Measurement of workpiece temperature;

(6) Check the deviation between the workpiece temperature and the set temperature;

(7) Check the reliability and sensitivity of the alarm system;

(8) Verification according to the provisions mentioned in the technical requirements;

(9) Verification of equipment trial operation stability.

After all project inspections and tests are completed, a final acceptance report will be written and will take effect after both parties agree and sign.

| Parameter | TECHPRO EQUIPMENT LLC |

| Models list | |||||

| Model(furnace capacity) | Input power(50/60HZ) | Output power | |||

| Rated power | Input voltage | DC voltage | IF voltage | IF frequency (KHZ) | |

| (KW) | (V) | (V) | (V) | ||

| GW--0.5T | 350 | 380 | 500 | 750 | 0.5-1 |

| GW--0.75T | 500 | 380 | 500 | 750 | 0.5-1 |

| GW--1T | 750 | 380 | 500 | 750 | 0.5-1 |

| GW--1.5T | 1000 | 380 | 500 | 750 | 0.5-1 |

| GW--2T | 1400 | 750 | 990 | 1500 | 0.5-1 |

| 380 | 500 | 750 | |||

| GW--3T | 2000 | 750 | 990 | 1500 | 0.5-1 |

| GW--5T | 3000 | 950 | 1254 | 1900 | 0.5-1 |

| GW--10T | 5000 | 1000 | 1320 | 1900 | 0.3-0.5 |

| GW--15T | 10000 | 1000 | 1320 | 1900 | 0.3-0.5 |

| GW--20T | 12000 | 1000 | 1320 | 1900 | 0.3-0.5 |

| GW--30T | 15000 | 1000 | 1320 | 1900 | 0.3-0.5 |

| Why Choose Us | TECHPRO EQUIPMENT LLC |

-

Equipped with built-in circulating water cooling system, equipment can be long-term work, no cleaning;electrical power components will not be damaged ; long life time;

Other manufacturers require users to directly tap water or groundwater cooling machine power; regularly with detergents water pipe cleaning equipment; and often because of poor water quality, so that equipment, furring channels, resulting in poor heat electrical components being blocked or damaged;

-

Configure automatic circuit breaker, with a reliable protection

Equipment power supply short circuit, open circuit, lack phase, power outages, discharge, and other circuit abnormalities are able to quickly and automatically cut off the power supply; in a timely manner to the equipment and network protection. To ensure the safety of the production operator.

Other manufacturers in general only with simple switch or without. They asked users to protect themselves with a fully functional power distribution equipment. Otherwise, there is short circuit, lack phase, or other circumstances occur. Will be because there is no protection, prone to accidents.

However, our equipments carry good protective function even without switch board prepared by the users.

| Packing & Delivery | TECHPRO EQUIPMENT LLC |