- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1580 KG

-

Type:

-

EXTRACTOR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Video technical support, Online support

-

Product name:

-

Pressure Vacuum Concentrate Herb Extractor Machine

-

Material:

-

Stainless Steel 304L 316L

-

Working Pressure:

-

Atm., vacuum, positive pressure

-

Solvent:

-

Water, ethanol, hexane or others

-

Capacity:

-

50L-500L

-

Voltage:

-

220V/380V

-

Composition:

-

Extractor, concentrator, chilling tank, storage tank

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TANLET

-

Model Number:

-

TNQ

-

Weight (KG):

-

1580 KG

-

Type:

-

EXTRACTOR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Video technical support, Online support

-

Product name:

-

Pressure Vacuum Concentrate Herb Extractor Machine

-

Material:

-

Stainless Steel 304L 316L

-

Working Pressure:

-

Atm., vacuum, positive pressure

-

Solvent:

-

Water, ethanol, hexane or others

-

Capacity:

-

50L-500L

-

Voltage:

-

220V/380V

-

Composition:

-

Extractor, concentrator, chilling tank, storage tank

Pressure Vacuum Concentrate Herb Extractor Machine

Main Feature

1. The Pressure Vacuum Concentrate Herb Extractor Machine consists of extractor, tubular heater, evaporator, condenser, oil-liquid separator, oil collector, medicine liquid pump, weighing vent, liquid storage tank, filter, vacuum pump, and electric cabinet. Defoamers are fixed in the steam outlet of the extractor and evaporator. The units without steam heating can be fixed with oil heating system.

2. It can be operate to hot recyling distill and condense, normal extraction, concentration, precipitation and percolation.

3. It can work in the condition of negative pressure, atm. and positive pressure. It can apply to distill water, ethanol and solvent, up to GMP standard.

4. The group has great advantages in multi-function, high efficiency, energy saving, and wide operation arrange. It pioneers in comprehensive capacity in nationwide; it is the pilot equipment in distilling natural herbal medicine, especially fit for research institution, universities and collages, and factory pilot experiment, or distilling valued medicine, or low temperature fresh herbal. It has been widely used in factories.

Application

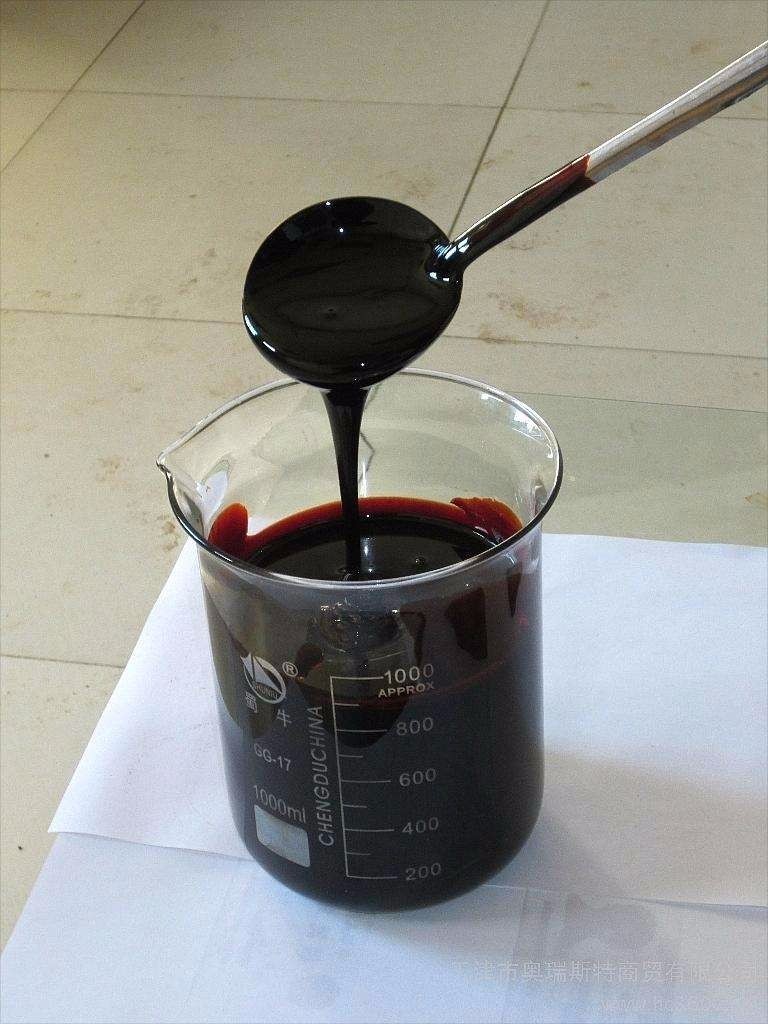

Extract Liquid

Main Parameters

Concentrate Cream

Extract Powder

|

Model and Specification

|

|

TNH-50

|

TNH-100

|

TNH-200

|

TNH-300

|

TNH-500

|

||||

|

Extraction Tank

|

Volume (L)

|

65

|

125

|

250

|

375

|

550

|

||||

|

|

Jacket Op. Pre. (MPa)

|

0.15

|

|

|

|

|

||||

|

|

Vessel Op. Pre. (MPa)

|

0.09

|

|

|

|

|

||||

|

Concentration Tank

|

Volume (L)

|

65

|

125

|

250

|

375

|

550

|

||||

|

|

Vessel Vacuum (MPa)

|

-0.08

|

|

|

|

|

||||

|

|

Heat Reflux (L/H)

|

20

|

40

|

80

|

120

|

180

|

||||

|

|

Motor (kw)

|

1.5

|

1.5

|

2.2

|

3

|

3

|

||||

Advantages

It has successfully enter into the international market because of multi-function, good performance, compact structure, and superior manufacture. It is widely used for pilot experiment in scientific research institution, university, college, factory; or extracting concentration of costly medicine.

Cutting

Plasma Welding

Mechanical Polishing

Assembly

Final Product

User Demand Analysis

Once the project is confirmed, the product level, processing technology and consulting group are analyzed according to the actual demands of customers so as to provide suitable engineering plans, form a complete production line and calculate the budget.

Engineering Design

We carry out planning and designs on details of engineering plans through introducing internationally advances design conception to provide valuable project technological plans and ensure effective implementation of all steps.

Product Manufacturing

The approved production drawing is the basis for production and manufacturing. All equipment that is not manufactured on the site shall be indentified by our quality responsible person so as to meet the strict stipulations.

Automatic Control Integration

The installation of the system and the whole automatic project meets the GMP standard. According to our years of experience, the installation and process rules will help simplify the starting and commissioning of equipment.

Trial Running and Training

During the equipment commissioning, our engineers will provide guidance on the site and carry out various tests with respect to all performances of the equipment with customers. Approval will be received from users.

Verification Services

To ensure normal production, we can set up maintenance and servicing plans for a single machine, the whole production line or the whole factory and provide equipment maintenance services and offer fittings according to customer requirements.

Delivery & Transportation

All delivery terms are available: EXW, FOB, CIF, CFR, DAF, DDP, CIP, etc.

Shipped in 45 days after the deposit confirmed.

Packing

The equipment and all accessories all packed in the wooden cases, to ensure safe shipping.

Payment Terms

T/T, L/C, Western Union, Paypal, Apple Pay, Online Payment, etc.

Here is a brief on us:

Since 1998

,

with 20+ years of experience

3 factories

totally covered 40,000+sq.m

.

Annually sales

$31.5 million

,

still keeps growing.

30+ R&D,

200+ employees professional service.

Leader

of this industry in nationwide

Click here to see more products Click here to contact us

Click here

to learn more about us

Click here

to see more Project Case