- Product Details

- {{item.text}}

Quick Details

-

Forming Time:

-

0.5-3m/min

-

Welding Mode:

-

seam welding

-

Welding Diameter:

-

100-1000

-

Dimensions:

-

1800*610*1930

-

Usage:

-

seam welding, Construction Pipe

-

Voltage:

-

380V

-

Weight (KG):

-

350 KG

-

Power (kW):

-

5.5kw

-

Product name:

-

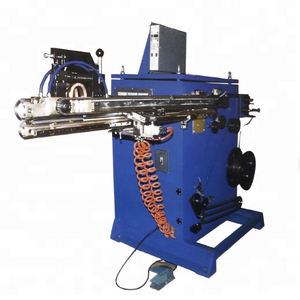

Circular Duct Pipe Air Straight Pneumatic Welding Machine

-

Thickness:

-

0.4-1mm

-

Color:

-

Customer's Requirement

-

Pipe shape:

-

round

-

Weight:

-

890KG

-

Power:

-

3000W

-

Application:

-

Metal Sheet

-

Material:

-

Stainess Steel

-

MOQ:

-

1 Set

-

Features:

-

High Efficiency

Quick Details

-

Marketing Type:

-

New Product

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WDL

-

Forming Time:

-

0.5-3m/min

-

Welding Mode:

-

seam welding

-

Welding Diameter:

-

100-1000

-

Dimensions:

-

1800*610*1930

-

Usage:

-

seam welding, Construction Pipe

-

Voltage:

-

380V

-

Weight (KG):

-

350 KG

-

Power (kW):

-

5.5kw

-

Product name:

-

Circular Duct Pipe Air Straight Pneumatic Welding Machine

-

Thickness:

-

0.4-1mm

-

Color:

-

Customer's Requirement

-

Pipe shape:

-

round

-

Weight:

-

890KG

-

Power:

-

3000W

-

Application:

-

Metal Sheet

-

Material:

-

Stainess Steel

-

MOQ:

-

1 Set

-

Features:

-

High Efficiency

Product Description

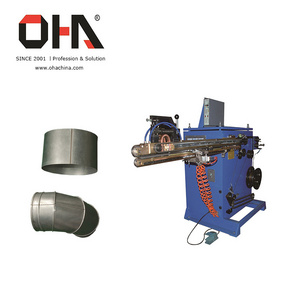

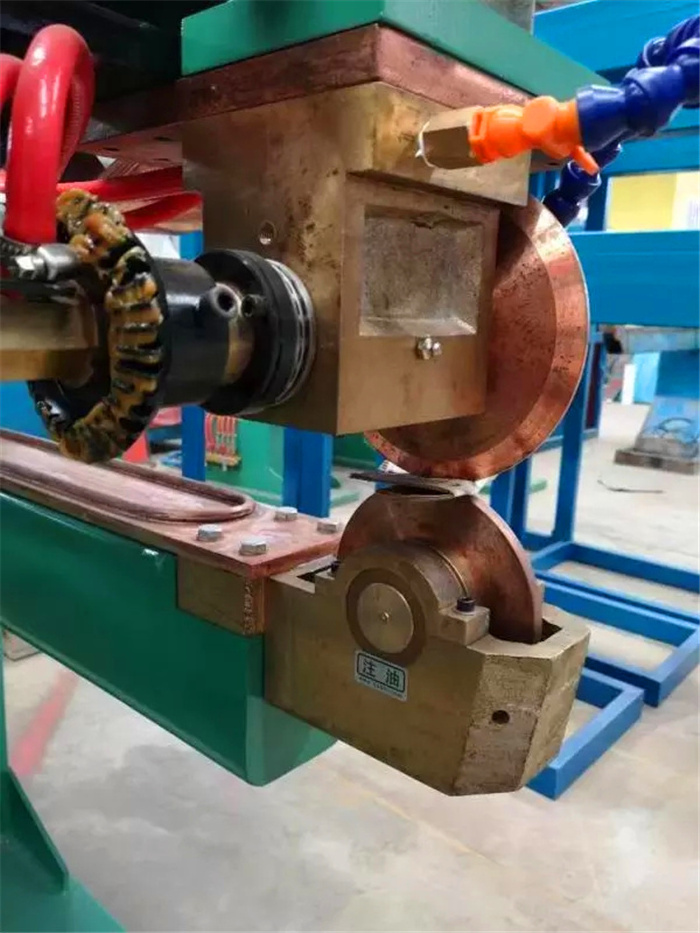

Stainless Steel Circular Duct Pipe Air Straight Pneumatic Seam Welding Machine

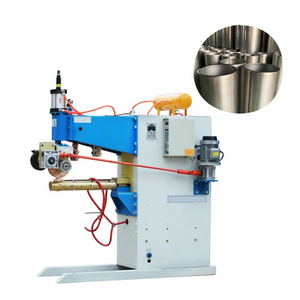

Seam welding machine refers to a Electric resistance welding machine where the weldment is assembled into a lap or butt joint and placed between two roller electrodes. The roller electrode pressurizes the weldment and rotates. Continuous or intermittent pulse power is transmitted to form a continuous weld. It can also be said that seam welding machines are an evolution of spot welding. Seam welding is widely used in the manufacturing of joints that require sealing, and sometimes it is also used to weld ordinary non sealing sheet metal parts. The thickness of the welded metal material is usually 0.1-2.5mm.

Detailed Images

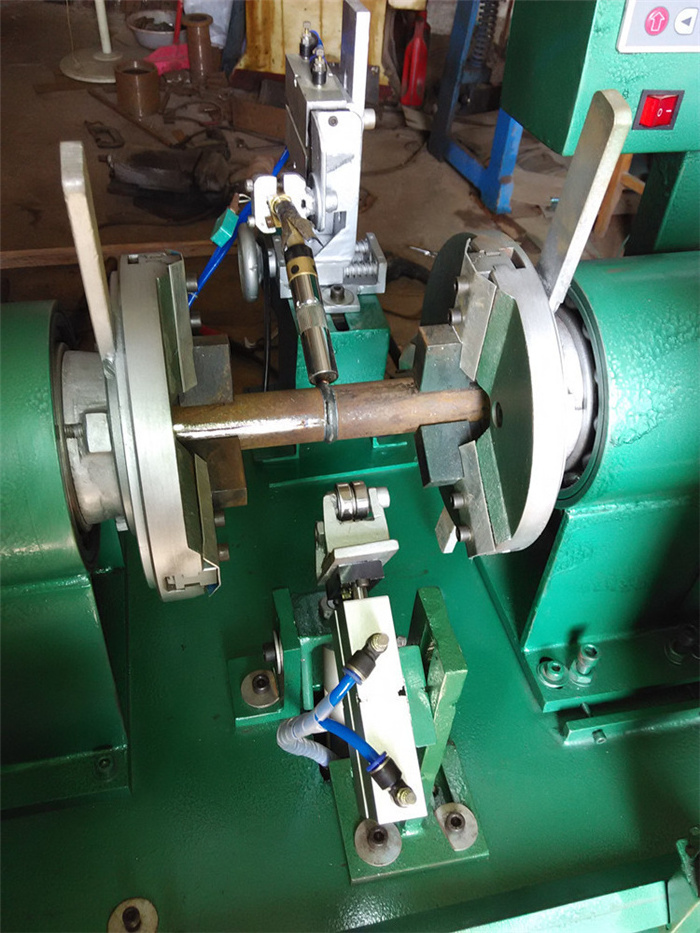

operational principle

During the formation process of seam welding joints (intermittent), each welding point also undergoes three stages: pre pressing, electric heating, and cooling crystallization. However, due to the rapid change in the relative position between the roller electrode and the weldment during seam welding, these three stages are not as distinct as those distinguished during spot welding. It can be considered that:

1) Under the direct compression of the roller electrode, the metal being heated by electricity is in the "electrified heating stage".

2) The adjacent metal that is about to enter the bottom of the roller electrode is subjected to a certain amount of preheating and partial pressure on the roller electrode, and is in the "pre pressing stage".

3) The adjacent metal that has just emerged from under the roller electrode begins to cool while still being subjected to pressure from the roller electrode, and is in the "cooling crystallization stage".

Therefore, the welding area under the roller electrode and the adjacent metal materials on both sides will be in different stages at the same time. For any solder joint on the weld seam, the process of passing through the roller is also a three-stage process of "pre pressing, electrification heating, and cooling crystallization". Due to the dynamic nature of the process, the pressure effect during the pre pressing and cooling crystallization stages is not sufficient, resulting in poor quality of seam welded joints compared to spot welding, which is prone to defects such as cracks and shrinkage cavities.

1. The FN long-arm seam welding machine is used to pressurize the electrode wheel butt welding while energizing, and the Joule heat generated by the contact resistance between the electrodes instantaneously melts the metal to achieve the seam welding under the action of the pulse. No need to add any solder, high efficiency and low cost. Easy to automate welding and other features.

2. Long arm design for welding deep barrels and special long sheets.

3. Advanced solder mask microcomputer controller, pulse welding principle: pulse frequency, pulse width, pulse base value, pulse amplitude are adjustable, to meet the requirements of high quality seam welding.

4. The main transformer adopts high-quality high-conductivity silicon steel sheet, and the forced water-cooling circulation system has large output power, low loss and high heat-insulating insulation grade.

5. The welding speed is not changed by the wear of the welding wheel. The welding machine works automatically, with a high degree of automation and productivity.

6. It is the most ideal equipment in the field of seam welding production of solar water heaters, water tanks, fuel tanks, pipelines, gas storage tanks, instrument casings, etc.

2. Long arm design for welding deep barrels and special long sheets.

3. Advanced solder mask microcomputer controller, pulse welding principle: pulse frequency, pulse width, pulse base value, pulse amplitude are adjustable, to meet the requirements of high quality seam welding.

4. The main transformer adopts high-quality high-conductivity silicon steel sheet, and the forced water-cooling circulation system has large output power, low loss and high heat-insulating insulation grade.

5. The welding speed is not changed by the wear of the welding wheel. The welding machine works automatically, with a high degree of automation and productivity.

6. It is the most ideal equipment in the field of seam welding production of solar water heaters, water tanks, fuel tanks, pipelines, gas storage tanks, instrument casings, etc.

Product Parameters

|

Model No.

|

Welding length(mm)

|

Min. diameter(mm)

|

Max diameter(mm)

|

|

FN-1000

|

1000

|

φ100

|

φ1000

|

|

FN-1500

|

1500

|

φ120

|

φ1000

|

|

FN-2000

|

2000

|

φ160

|

φ1000

|

|

FN-3000

|

3000

|

φ160

|

φ1000

|

Hot Searches