- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Customerized

-

Air Volume(Nm3/h):

-

10556-12370

-

Power Consumption(KW):

-

320

-

Heating Supplied(MW):

-

1.4

-

Hot Air Outlet Temperature:

-

200-300

-

Keyword:

-

Complete in Specifications Industrial Coal Wood Fired Hot Air Furnace

-

Color:

-

Customerized

-

Certification:

-

Customerized

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

YuTong

-

Dimension(L*W*H):

-

Customerized

-

Weight:

-

Customerized

-

Air Volume(Nm3/h):

-

10556-12370

-

Power Consumption(KW):

-

320

-

Heating Supplied(MW):

-

1.4

-

Hot Air Outlet Temperature:

-

200-300

-

Keyword:

-

Complete in Specifications Industrial Coal Wood Fired Hot Air Furnace

-

Color:

-

Customerized

-

Certification:

-

Customerized

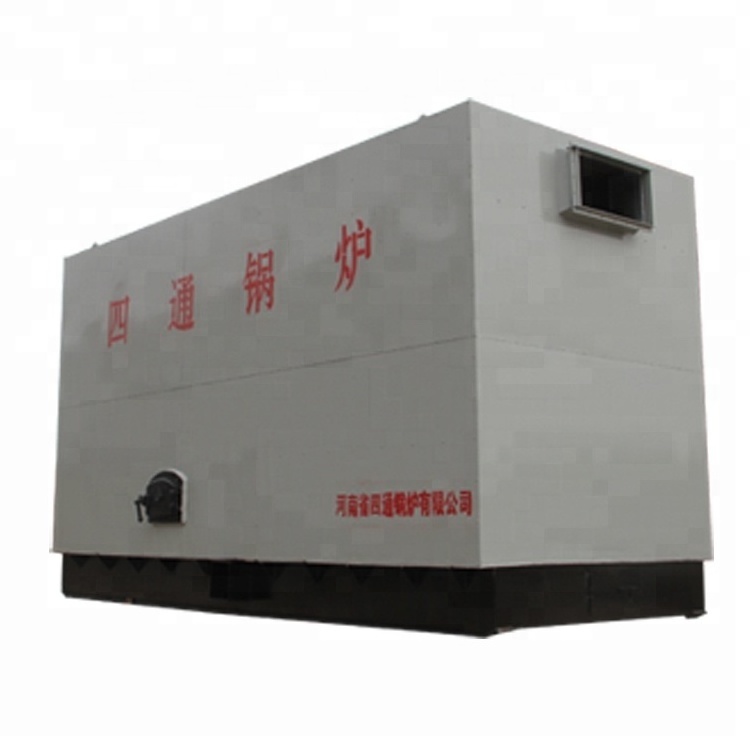

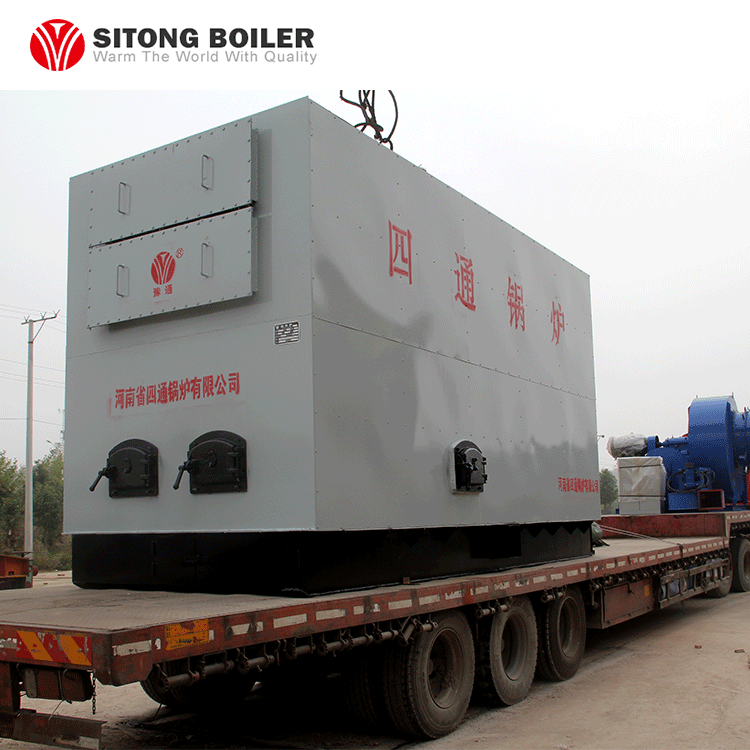

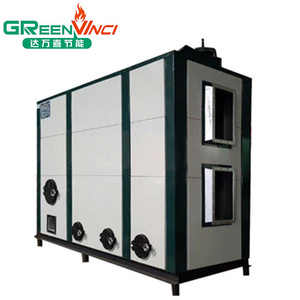

2000kg Biomass Wood Pellet Coal Indirect Hot Air Generator Stove for Rotary Dryer Drying System

Dear Customer:

We have a Trade Assurance Amount US $168,000 granted by Alibaba.com. It means you will receive 100% refund of the Trade Assurance Amount for orders not meeting agreed delivery or quality terms.

Features:

1.LRF series hot air stove is for heating; with spiral With clean air as media;

2.Offering direct heat resource for different industries.

3.Heat temperature: low temperature 80~150°C; middle temperature 200~300C; high temperature 400~550°C;

4.This hot air furnace is widely used in chemical industries drying, food drying, medicine drying, tobacco drying, ceramics drying, painting drying, dewatering drying ; heating of plate, warm house,poultry warehouse;

5.Underground mine, underground moisture removing, warming process;

Working Principle:

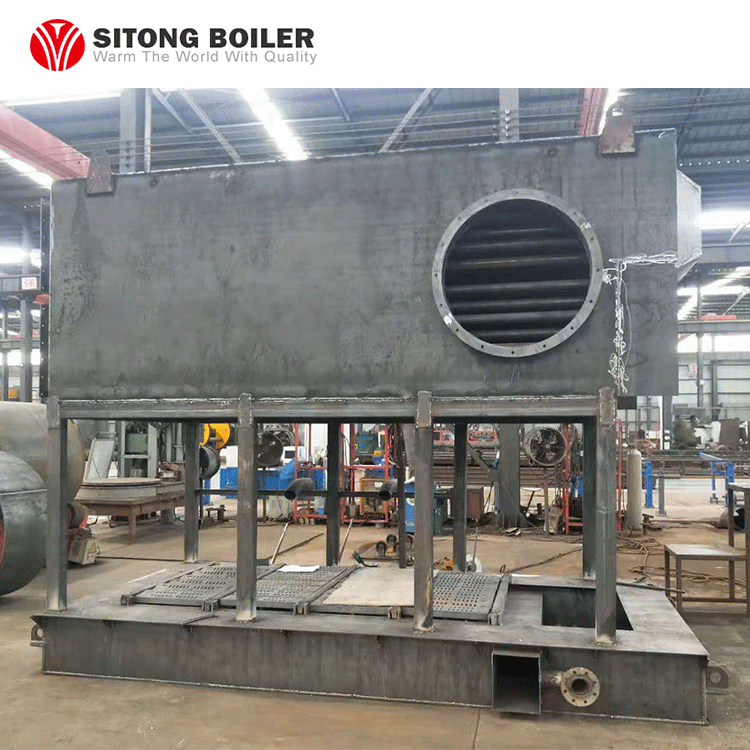

The hot air stove combustion chamber and heat exchanger in one combined, using the structure of full steel plate multilayer sleeve type, it's consumption chamber in the below of furnace center, circles heat exchanger in the upper and around, air and flue gas are two-pass, flow separately in heat exchanging. In order to improve thermal efficiency, the multiple head helical groove plate heat exchanging technology and turbulent flow principle, thinning laminar flow thickness, make the air and flue gas constantly exchange revolving on the march, greatly strengthened the heat transfer effect.

The main work process:

It produce high temperature flue gas in the furnace by burning of coal, go into smoke ring under the action of fan, and after the heat exchanging with the outside air, through the flue gas ducting and then discharged by chimney, the cold air blow into the shell of the stove ny blower, getting into furnace lateral air ring through furnace arch the stove chamber into the lateral air ring, and supply clean hot air equipment by hot air outlet piping.

Main Equipment:

The hot air stove mainly consists of the grate stoker, refractory bricks, baffle board, hot air stove proper, the flue gas ducting and wind inlet pipe, dust collector, chimney and its bracket, induced draft fan (including adjusting valve), blower (including adjusting valve) and special temperature measuring instrument etc.

The equipments are all from domestic, its performance guideline reach to national advanced level.

Performance Characteristics:

1. The fuel is coal.

2. The hot air boiler use the pure hot air as the medium, no pollution.

3. Low power consumption, higher thermal efficiency.

4. Auto measuring temperature and displaying.

5. Simple operation, easy to use.

|

Model |

WRF

10Y(Q) |

WRF

20Y(Q) |

WRF

40Y(Q) |

WRF

60Y(Q) |

WRF

80Y(Q) |

WRF

100 Y(Q) |

WRF

120 Y(Q) |

WRF

180 Y(Q) |

WRF

240 Y(Q) |

WRF

300 Y(Q) |

WRF

400 Y(Q) |

|

| Heat Supplied (MW) | 0.12 | 0.24 | 0.47 | 0.7 | 0.93 | 1.17 | 1.4 | 2.1 | 2.8 | 3.5 | 4.7 | |

| Air Temperature | 60-400 | |||||||||||

| Medium | Air | |||||||||||

| Design | Natural gas, city gas, marsh gas, methyl alcohol, diesel oil, liquefied gas, etc. | |||||||||||

| Thermal Efficiency(%) | 85 | |||||||||||

| Dimension |

Length

(mm) |

2200 | 2600 | 3300 | 3900 | 4500 | 5000 | 5200 | 5600 | 5800 | 6000 | 7000 |

|

Width

(mm) |

1200 | 1400 | 1600 | 1800 | 1900 | 2000 | 2100 | 2400 | 2700 | 3100 | 3400 | |

|

Height

(mm) |

1450 | 1650 | 1850 | 2050 | 2150 | 2250 | 2350 | 2650 | 2950 | 3350 | 3650 | |

| Gross Weigh(Kg) | 1860 | 2560 | 4250 | 5100 | 6000 | 7500 | 8800 | 13800 | 17800 | 21800 | 25800 | |

| Note: Data is for reference only, if any changes should follow the actual drawing. | ||||||||||||

Why Choose us?

1.Chinese Famous Brand

2.Super High Quality, Competitive Price

3.Big Production Ability

4.Fast Delivery, Excellent After-sale Service

5.Certificate ISO9001, ASME, ISO14001, SGS, CE, BV

Advanced Boiler Manufacturing Equipment: