- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V

-

Key Machines:

-

valve

-

Product name:

-

rotary valve

-

motor:

-

380V, 220v

-

Size:

-

DN

-

Color:

-

Customer's Request

-

Body material:

-

SS304

-

Packing:

-

Wooden Case

Quick Details

-

Machinery Capacity:

-

2 t/h

-

Brand Name:

-

DF SPEED

-

Weight:

-

85 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V

-

Key Machines:

-

valve

-

Product name:

-

rotary valve

-

motor:

-

380V, 220v

-

Size:

-

DN

-

Color:

-

Customer's Request

-

Body material:

-

SS304

-

Packing:

-

Wooden Case

Virtual Show

Product information

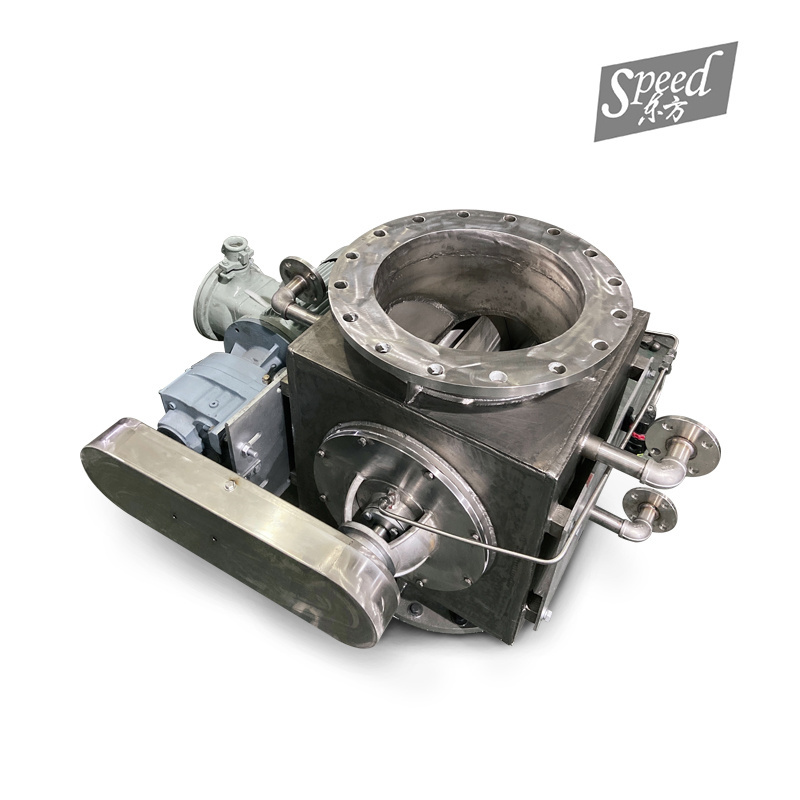

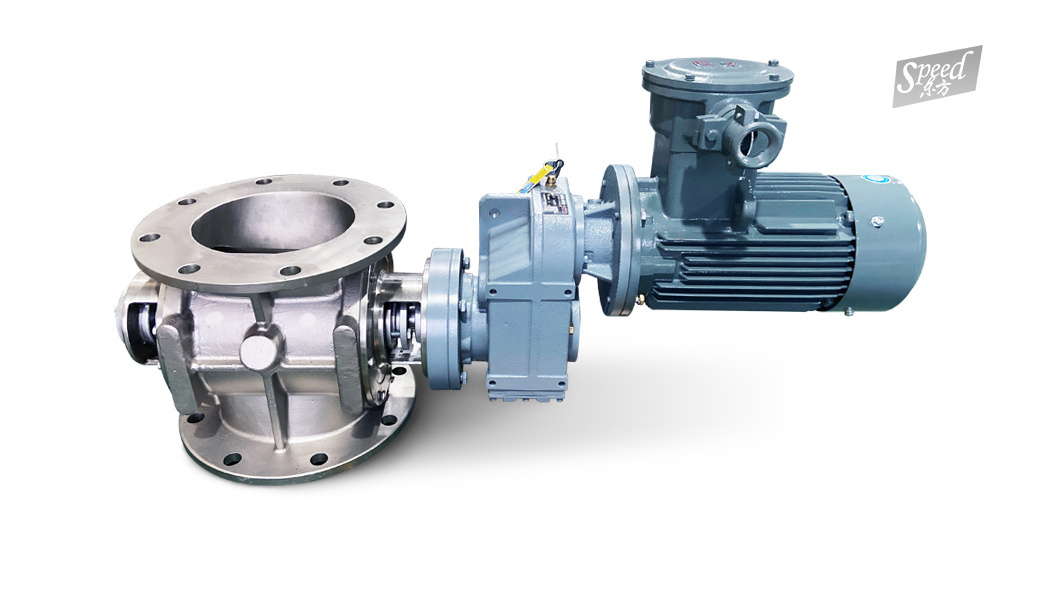

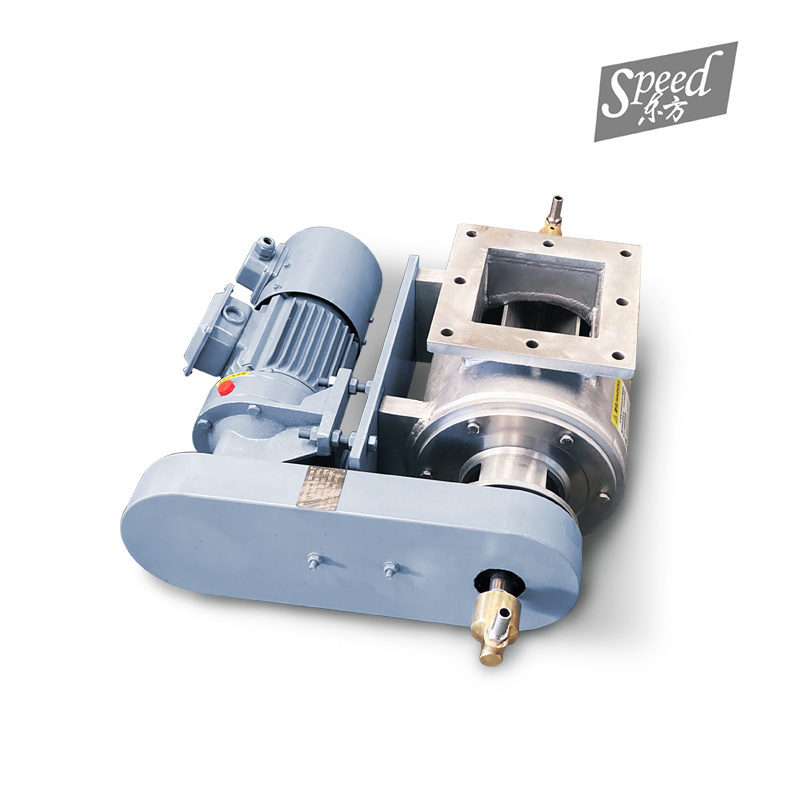

Airlock valve,also named discharge valve,star discharger, cindervalve,is an important equipment for pneumatic conveying system and dust removal system.

It is mainly used to discharge the material continuously from the tripper and dust collector,and make sure the inner pressure not exposed to atmosphere pressure evironment.

The airlock valve is made of gear motor,sealing element,impellers and rotor housing on which many rotating blades are set.It is capable of discharging powder,small particles,flaky or fibre continuously by the differential pressure of material.Now it has been widely used in chemical,pharmacy,drying,grains,cement,environmental protection and power industry etc.

Product Details

Working Principle

Material falls onto the blades and rotates with the blades to the outlet under the airlock valve.Material can be discharged

continuously.

In pneumatic conveying system,the airlock valve can lock the air and supply material continuously. The low speed of the rotor and

tiny space can prevent the airflow from reverse flow,and ensure a stable air pressure and regular discharge of the material.

The arilock valve acts as the material discharger in the material collecting system.

continuously.

In pneumatic conveying system,the airlock valve can lock the air and supply material continuously. The low speed of the rotor and

tiny space can prevent the airflow from reverse flow,and ensure a stable air pressure and regular discharge of the material.

The arilock valve acts as the material discharger in the material collecting system.

|

To choose perfect rotary airlock valve , please confirm:

|

|

|

|

|

||||

|

1. The capacity(Tons/Hour)

|

|

|

|

|

||||

|

2. The diameter of the inlet and oulet flange

|

|

|

|

|

||||

|

3. Pressure : negative positive ()Mpa?

|

|

|

|

|

||||

|

4. What’s the material to be convey?The specific gravity and the moisture content

|

|

|

|

|

||||

|

5. The voltage ?

|

|

|

|

|

||||

|

6. Other special requirement, like brand of the motor ,height of the rotary valve etc.

|

|

|

|

|

||||

|

7. It is better if you have layout drawing or sketch .

|

|

|

|

|

||||

Hot Searches