- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

none

-

Power (kW):

-

12 kW

-

Weight (KG):

-

3500 KG

-

raw material:

-

600-1200mm waste tire

-

control way:

-

semi-auto system

-

cooling way:

-

water cooling system

-

capacity:

-

from 200kg/h to 500kg/h

-

type:

-

recycled machinery tyre

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

eenor

-

Voltage:

-

220V to 510V

-

Dimension(L*W*H):

-

none

-

Power (kW):

-

12 kW

-

Weight (KG):

-

3500 KG

-

raw material:

-

600-1200mm waste tire

-

control way:

-

semi-auto system

-

cooling way:

-

water cooling system

-

capacity:

-

from 200kg/h to 500kg/h

-

type:

-

recycled machinery tyre

recycled machinery tyre/machines of tyre recycling/used tyre pyrolysis recycling plant

1. GENERAL:

This production line including main machine and accessorial equipment, it is used for recycling scrap-tire (steel tyre and textile tyre), the final product is rubber powder or reclaimed rubber.

2.Process flow:

waste tyre--cutting loop mouth--cutting strip--cutting dice crushing filtering--magnetic separating filtering--finished products

3.Processing method:

Physic mechanical crushing method at normal temperature of waste tyre:nochemical raw material is required,no waste gas,washte water and soot are discharged, and the cooling water of the equipment is reused,no emission,equipment noise is within the range specified by the country(GB20055-2006),fineness of rubber powder produced by it is adjustable(10 meshes to 30 meshes),take waste tyre as example,the process is as follows:breaking down,crushing,filtering,magnetic separating,grin-ding,then the finished products are produced.

1).Tyre bead ring cutting off machine:

This machine mian to cut the inner dimater of the tyre, and cut the side of the tyre to the next step of segmentation.

|

Motor power |

Working range |

Working quatity |

Size of figure |

weight of equipment |

|

2.2kw |

750-1200tyre |

25-30strips/h |

1150*850*1200 |

0.5ton |

2).Tyre bead steel ring seperator:

Tyre bead steel ring seperator by double cell extrusion, and the two grooved roller speed differential will ring in the mouth than the wire separation, maintaining good physicalproperties of steel wire, rubber can then use it to avoid environmental pollution.

|

Motor power |

Working range |

Size of discharge |

Size of equipment |

Weight of euipment |

|

15kw |

1 mouth of tyre need1 miutumines |

1.2*500*20 |

1500*1100*1200 |

1.8ton |

3).tyre strips cutting machine:

Strips cutting machine can cut cycle machine to remove the wire tire sidewall cut into strips, and the width of the adjustable section. Two circular knives for specialmaterials, hard and durable, can be used repeatedly grinding for no more than 1200 steel tires.

|

Motor power |

Working range |

Working diamater |

Size of discharge |

Size of equipment |

Weight of equipment |

|

5.5kw |

10strips/h |

Less 1200 |

35-55 |

1230*650*1580 |

0.8ton |

4).tyre rim cutting machine:

Cutting machine can cut a tire strip, cut block, tool for the alloy cutting tools, nearly 9-11 tons per day, cutting tools are not sharp and repeated grinding

|

Motor power |

Working quitaty |

Size of discharge |

Size of equipment |

Weight of equipment |

|

7.5kw |

0.8-1.5t/h |

35*35*35 |

780*550*1210 |

0.6ton |

|

Host |

Equipment |

Quantity |

Equipment Description and Function |

|

Rubber crusher |

1 |

The waste tire rubber and miscellaneous plastic pieces were breaking milling cycle |

|

|

Equipment |

Ring cutter |

1 |

Will tire side and tire top joint use a knife to slice; Make the side of the tire and tire top complete separation |

|

Strips cutter |

1 |

Will be cut into strips the tire sidewall, tire I circle reserved |

|

|

Rim cutter |

1 |

The tires will be cut into strips cut into 3.5 cm square block |

|

|

Big Shaker |

1 |

The powder for the first time separation (8 - 10 mesh) |

|

|

Small shaker |

1 |

The powder for the second time separation (20-30mesh) |

|

|

Large conveyor |

1 |

It is used for transportation does not meet the requirements of mesh powder to return the host to continue breaking |

|

|

Magnetic separation unit |

1 |

The powder was extracted in the separation of the metal wire |

|

|

Fiber separator. |

1 |

The powder was extracted in the wool fiber |

|

|

Steel separator |

1 |

will tire of crude steel mouth ring and rubber parts completely separated |

|

|

Remarks |

Above unit is in the process of tires used to crush the machine |

||

XKP400 rubber crusher:

Output: 4500-6000kg/24 hour for about 20 mesh granule.

XKP450 rubber crusher:

Output :7000-12000kg/24 hour for about 20 mesh granule.

XKP560 rubber crusher:

Output : 10000-17000kg/24 hour for about 20 mesh granule.

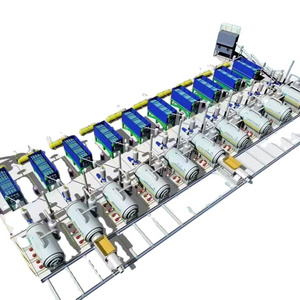

4.THE OVERALL PHOTOS OF THE COMPLETE LINE

(Ring cutter--Stips cutter--rim cutter--steel wire separator)

( Double Roll Rubber Crusher )

(Fiber Separator )

(Rubber grinder)

FAQ

1Q: Are you a factory or trading compamy?

A: We are a factory.

2Q: Where is your factory? How can I visit?

A: Our factory is located in Qingdao China. You can fly to Qingdao Liuting airport, then we can pick you up to our factory. Warm welcome to visit us.

3Q: How does your factory control the quality of machines and after sales service?

A: Our machine passed CE, BV, ISO, SGS certification. All of our machines have one year guarantee, and will provide lifetime maintenance

If you are intrested in our machine, pls contact me freely by return email.We also can according to the customers' requirement of the production capacity to design the different type of the production line.