24-HOUR ONLINE SERVICE:

Contact: Amber Min

Tel/Whatsapp: +8615652556306

Email:sales02@sinogoldmachine.com

Pls contact whtasapp directly for quick reply.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V,50hz

-

Dimension(L*W*H):

-

1580 X 860 X 640 mm

-

Power (kW):

-

14KW

-

Weight (KG):

-

180 KG

-

Name:

-

Hot sale fiberglass chopper resin spray machine with gun

-

Driven Mode:

-

Pneumatic

-

Whole Power:

-

14KW

-

Maximum output:

-

2.5L-6L/min spray resin

-

Working pressure:

-

80(N/S)

-

Air Consumption:

-

Above 23cfm

-

Hose Assembly:

-

15 meters Hoses

-

Air inlet: 16mm Fluid inlet:

-

3/8"

-

Machine size:

-

770mm*560mm*1350mm

-

Gross weight:

-

180KG

-

Marketing Type:

-

New Product 2021

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CNMC

-

Machine Type:

-

Fiberglass Spray Machine

-

Voltage:

-

220V,50hz

-

Dimension(L*W*H):

-

1580 X 860 X 640 mm

-

Power (kW):

-

14KW

-

Weight (KG):

-

180 KG

-

Name:

-

Hot sale fiberglass chopper resin spray machine with gun

-

Driven Mode:

-

Pneumatic

-

Whole Power:

-

14KW

-

Maximum output:

-

2.5L-6L/min spray resin

-

Working pressure:

-

80(N/S)

-

Air Consumption:

-

Above 23cfm

-

Hose Assembly:

-

15 meters Hoses

-

Air inlet: 16mm Fluid inlet:

-

3/8"

-

Machine size:

-

770mm*560mm*1350mm

-

Gross weight:

-

180KG

-

Marketing Type:

-

New Product 2021

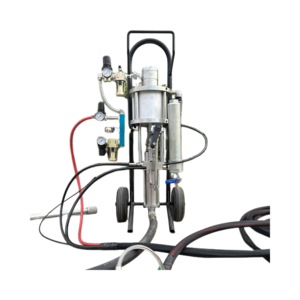

Fast delivery FRP Spray Machine Fiberglass chopper resin spray machine

The CNMC-CZ fiberglass spray equipment machine is used to apply the resin and fiber on work piece

surface simultaneously. It is the modern technology to save resin consumption and

labor cost compare to hand lay-up technology, which is widely used for FRP or GRP

product in mass production.

1.Accurate ratio control. Catalyst slave pump for exact catalyst ratio ensures the parts cured at desired rate.

2.Environment friendly. Airless spraying decreases the volatilization and less pollution.

3.Cart & System. The whole system is mounted on a cart chassis which makes the equipment moveable, benefits the spraying flexible.

4.Roving management. The roving is guided by the boom crutch to make the roving smooth, less tangling, more uptime.

5.Compact & light weight.

6.American Gun available.

7.One year guarantee.

surface simultaneously. It is the modern technology to save resin consumption and

labor cost compare to hand lay-up technology, which is widely used for FRP or GRP

product in mass production.

1.Accurate ratio control. Catalyst slave pump for exact catalyst ratio ensures the parts cured at desired rate.

2.Environment friendly. Airless spraying decreases the volatilization and less pollution.

3.Cart & System. The whole system is mounted on a cart chassis which makes the equipment moveable, benefits the spraying flexible.

4.Roving management. The roving is guided by the boom crutch to make the roving smooth, less tangling, more uptime.

5.Compact & light weight.

6.American Gun available.

7.One year guarantee.

Specification

|

Name

|

Fiberglass Spray Machine

|

|

Driven Mode

|

Pneumatic

|

|

Whole Power

|

14kw

|

|

Standard Nozzle

|

1.4 mm 2.5L-6L/min spray resin

|

|

Operating Pressure

|

45 to 60 PSI (3.0 to 4.0 bar)

|

|

Pattern Width

|

200 to 500 mm

|

|

Air Consumption

|

Above 23cfm

|

|

Paint Tank Operating Pressure

|

Optimal 25-30 PSI

|

|

Hose Assembly

|

15 meters Hoses

|

|

Air inlet

|

16mm Fluid inlet: 3/8"

|

|

Voltage

|

110V/220V/230V 1-ph & 380V/400V 3-ph

|

|

Machine size

|

770mm*560mm*1350mm

|

|

Gross weight

|

180kg

|

Product Description

Title goes here.

Hot Searches