Free

giving a conventional brick mold, and brick molds can also be customized according to demand.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan

-

Brand Name:

-

ChengHui

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1500*1300*1800mm, 1500*1300*1800mm

-

Marketing Type:

-

New

-

Weight (KG):

-

960 kg

-

Raw Material:

-

Concrete/Cement

-

Block Type:

-

Paving Bricks

-

Color:

-

According to customer requirements

-

Model:

-

4-40

-

Brick Type:

-

Hollow Brick Concrete Brick

-

Machine Type:

-

Semi Automatic

-

Capacity:

-

Model customization

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan

-

Brand Name:

-

ChengHui

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1500*1300*1800mm, 1500*1300*1800mm

-

Marketing Type:

-

New

-

Weight (KG):

-

960 kg

-

Raw Material:

-

Concrete/Cement

-

Block Type:

-

Paving Bricks

-

Color:

-

According to customer requirements

-

Model:

-

4-40

-

Brick Type:

-

Hollow Brick Concrete Brick

-

Machine Type:

-

Semi Automatic

-

Capacity:

-

Model customization

Product Overview

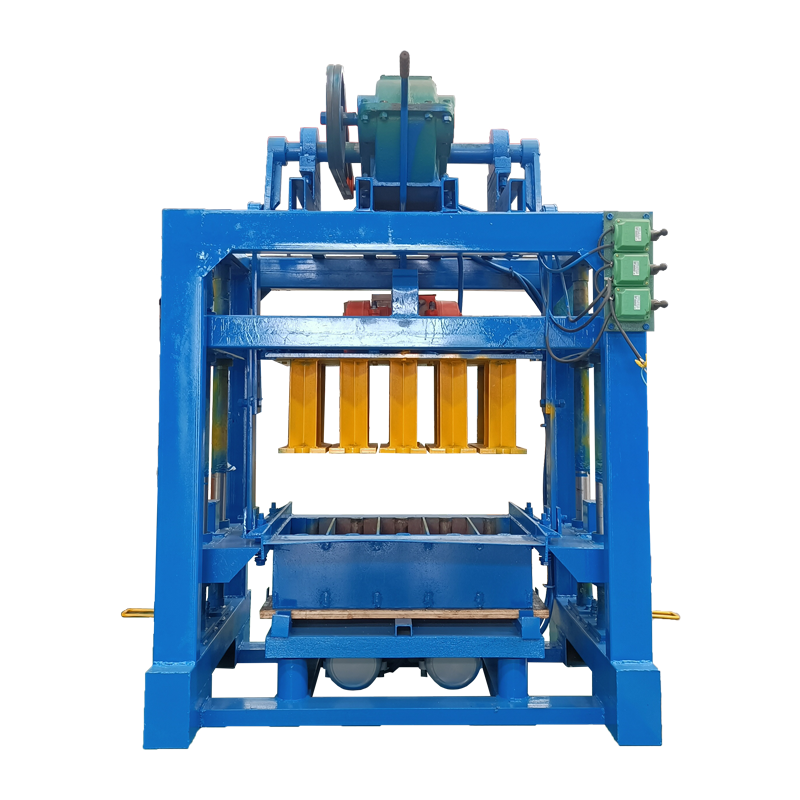

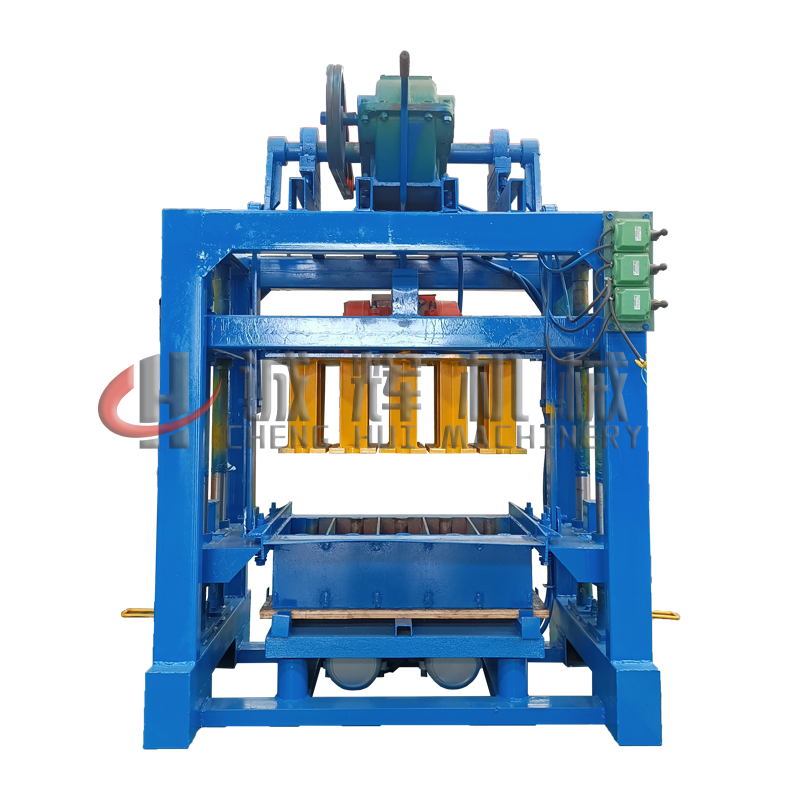

Solid Paving Brick Making Machine Long Service Life Lego Block Making Machine

This 4-40 semi-automatic concrete bricks making machine. The brick making principle of the block brick machine is through vibration extrusion molding, which ensures the denseness of the bricks, shortens the molding cycle and improves the production efficiency. low cost, low investment, high efficiency, saving energy consumption.

FEATURES AT A GLANCE

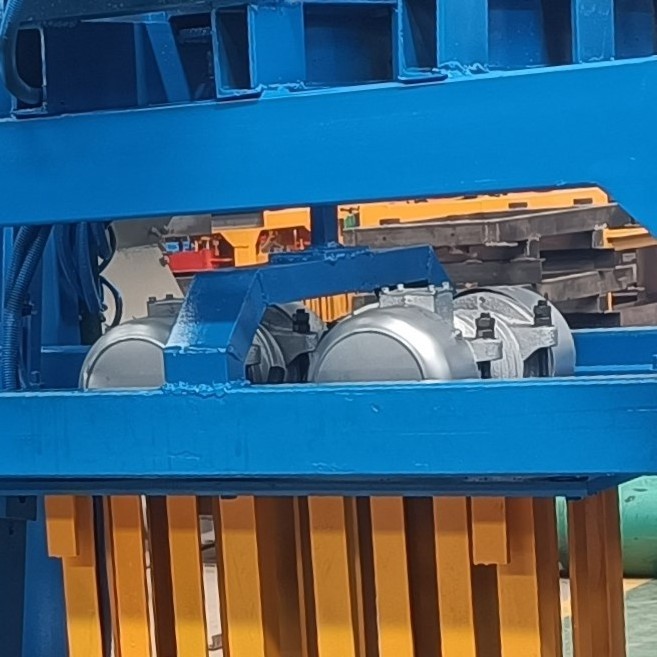

High Quality Motor

ChengHui Machinery uses high-quality motors to ensure that the vibration intensity reaches the standard.

High Quality Block Molds

The mould are all treated by High temperature carburizing.The service life are 3 times longer than normal one.

Control Button

Simple and convenient operation

National Standard Steel Frame

High hardness and strong wear resistance

Advantage

1. Save manpower and material resources, improve production efficiency, environmental protection and energy saving.

2. The bricks produced have high strength and good density, and can be stacked and dried at any time.

3. The mold can be replaced at will, truly realizing one machine with multiple uses.

4. Consumable parts are not only convenient for maintenance, but also users can save mold costs.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

||

|

1

|

Model

|

4-40

|

||

|

2

|

Power

|

7.5KW

|

||

|

4

|

Machine Dimension

|

1500*1300*1800mm

|

||

|

5

|

Packaging Dimensions

|

1550*1350*1850mm

|

||

|

6

|

Weight

|

1100kg

|

||

|

The transmission structure of the concrete hollow block forming machine adopts mechanical transmission, which can make reasonable and effective use of mechanical power. The feeding and forming parts use various transmission devices to complete various actions, which are stable, durable and easy to maintain.

|

|

|

||

Application field

Various

raw

materials

applicable: Coal Gangue, Shale, Fly ash , slag etc.

4-35 Semi-automatic bricks making machine multifunctional, the applicability is strong, with different molds can produce a variety of shapes and specifications of the block wall, the road block, block, and other flowers cell wall.

Concrete cement bricks can produce different types of bricks.

It can also be

customized

according to demand.

Free

drawings are provided to customers who need customized brick types

Successful Project

Project in

Zimbabwe

Project in

Ghana

Project in

Jamaica

Brick machine production line in Hebei China

Packing and Shipping

Similar Products

Certain Suppliers

1. The mold of the brick making machine is not precise enough, which affects the brick forming effect, resulting in the collapse of the shaped bricks.

2.

Inferior vibration motors cannot reach the calibrated power, and insufficient vibration intensity will cause the raw materials to be unable to be fully compacted and the interior of the bricks to be loose.

ChengHui Machinery

1. ChengHui Machinery’s mold plates use laser cutting technology with an error as low as 1 mm.

2. ChengHui Machinery uses high-quality motors to ensure that the vibration intensity reaches the standard.

CHENGHUI MACHINERY EQUIPMENT CO., LTD.

Chenghui Machinery Equipment Co., Ltd. is located in Gongyi City, Henan Province. It is an enterprise integrating R&D, production and sales, mainly focusing on brick machine equipment. The equipment we produce sells well both at home and abroad. Chenghui Machinery has a complete service system and has created an experienced service team to plan sites, design installation basic drawings and flow charts for customers free of charge, and provide professional technical training.

FIRST CLASS PERFORMANCE

Chenghui Machinery has nearly 18 years of production experience, and its quality and price are very competitive. Machine long service life, mould by carburizing heat treatment, finished bricks high strength and pressure.

FAQ

Q1:What is the warranty for this machine?

A1:3 years excluding the easy wear parts.Spare parts is recommended to keep at least one year in case of emergency

Q2: What kind of material is this machine made of ?

A2: Stainless steel and carbon steel.

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.

Q2: What kind of material is this machine made of ?

A2: Stainless steel and carbon steel.

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.

Hot Searches