- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/50hz/3phase

-

Power:

-

38-285KW

-

Dimension(L*W*H):

-

6000*3000*7000mm

-

Weight:

-

7000 kg

-

Title:

-

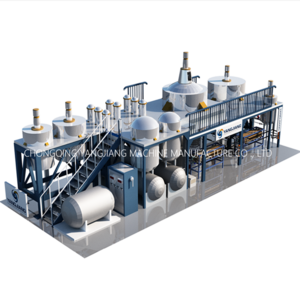

Hot Sale Oil Mini Refinery for Producing Base Oil in Turkey

-

Function:

-

recycle waste lube oil into quality base oil

-

Raw material:

-

Stainless Steel/carbon steel/boiler steel

-

Energy consumption:

-

10^5 kcal/t

-

Recovery rate:

-

80%--90%

-

Control System:

-

Automatic Control/Batch

-

Chemical cost:

-

30 USD/T

-

Product quality:

-

light yellow; no foul smell; SN150-SN300

-

End oil color:

-

NO.1----NO.1.5

-

Environmental protection:

-

no waste gas; no waste water; eco-friendly

Quick Details

-

Flow:

-

1~30tons/day

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

TONGRUI

-

Voltage:

-

380v/50hz/3phase

-

Power:

-

38-285KW

-

Dimension(L*W*H):

-

6000*3000*7000mm

-

Weight:

-

7000 kg

-

Title:

-

Hot Sale Oil Mini Refinery for Producing Base Oil in Turkey

-

Function:

-

recycle waste lube oil into quality base oil

-

Raw material:

-

Stainless Steel/carbon steel/boiler steel

-

Energy consumption:

-

10^5 kcal/t

-

Recovery rate:

-

80%--90%

-

Control System:

-

Automatic Control/Batch

-

Chemical cost:

-

30 USD/T

-

Product quality:

-

light yellow; no foul smell; SN150-SN300

-

End oil color:

-

NO.1----NO.1.5

-

Environmental protection:

-

no waste gas; no waste water; eco-friendly

| Product details |

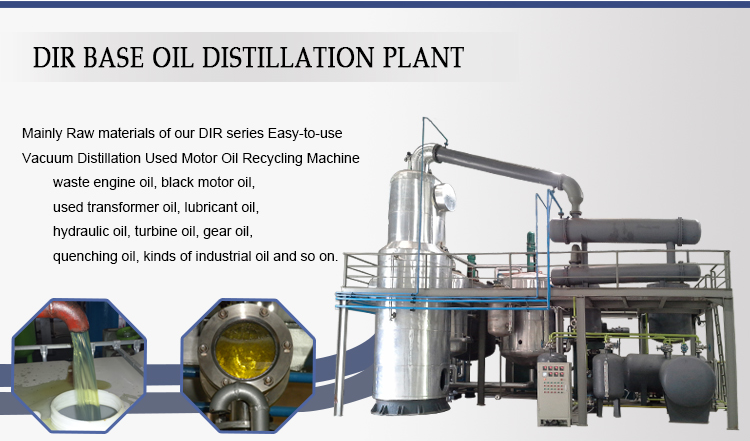

Mainly Raw materials of our DIRseries oil distillation machine

waste engine oil, black motor oil , used transformer oil, lubricant oil, hydraulic oil, turbine oil, gear oil, quenching oil, kinds of industrial oil and so on.

What can we get from DIR series waste engine oil distillation machine?

DIR is mainly used to change waste oil into clean base oil. The final base oil will be SN150-SN500 . The base oil can be used as the raw materials of kinds of usable oil, such as new engine oil, new motor oil, new lubricant oil and so on

| Parameters | DIR-1 | DIR-2 | DIR-3 | DIR-4 | DIR-5 | DIR-6 | DIR-7 | DIR-8 | |

| Capacity | 1T/D | 2T/D | 3T/D | 4T/D | 5T/D | 6T/D | 8T/D | 10T/D | |

| Total Power | 49KW | 59KW | 69KW | 78KW | 82KS | 90KW | 110KW | 120KW | |

| Rated Power | 68KW | 80KW | 100KW | 110KW | 125KW | 140KW | 150KW | 165KW | |

| Vacuum Degree | -50Pa | ||||||||

| Heating Method | gas/electric | ||||||||

| Oil Heating Temp | 180℃-270℃ | ||||||||

| Voltage | 220V/380V/415V | ||||||||

| Noise | ≤60dB | ||||||||

| Dimension | 7*6*7.5M | 8.5*6.5*7.5M | 9*7*7.5M | 9.5*7.5*7.5M | 10*8*7.5M | 11*8.5*7.5M | 13*9*7.5* | 15*10*7.5M | |

What can we get from DIRseries waste engine oil distillation machine?

It is mainly used to change waste oil into clean base oil . The final base oil will be SN150, SN250, SN300 . The base oil can be used as the raw materials of kinds of usable oil, such as new engine oil, new motor oil, new lubricant oil and so on.

You can build one production line for waste oil into new engine oil, or you can sell the base oil to other oil manufacturers directly.

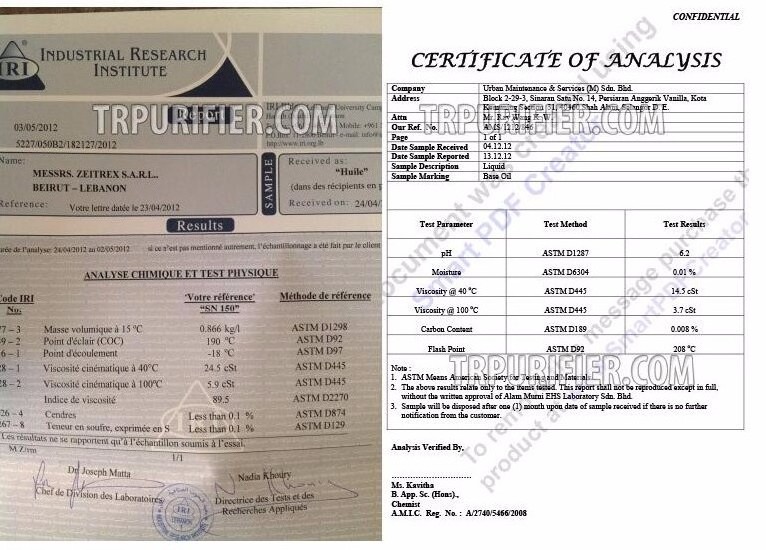

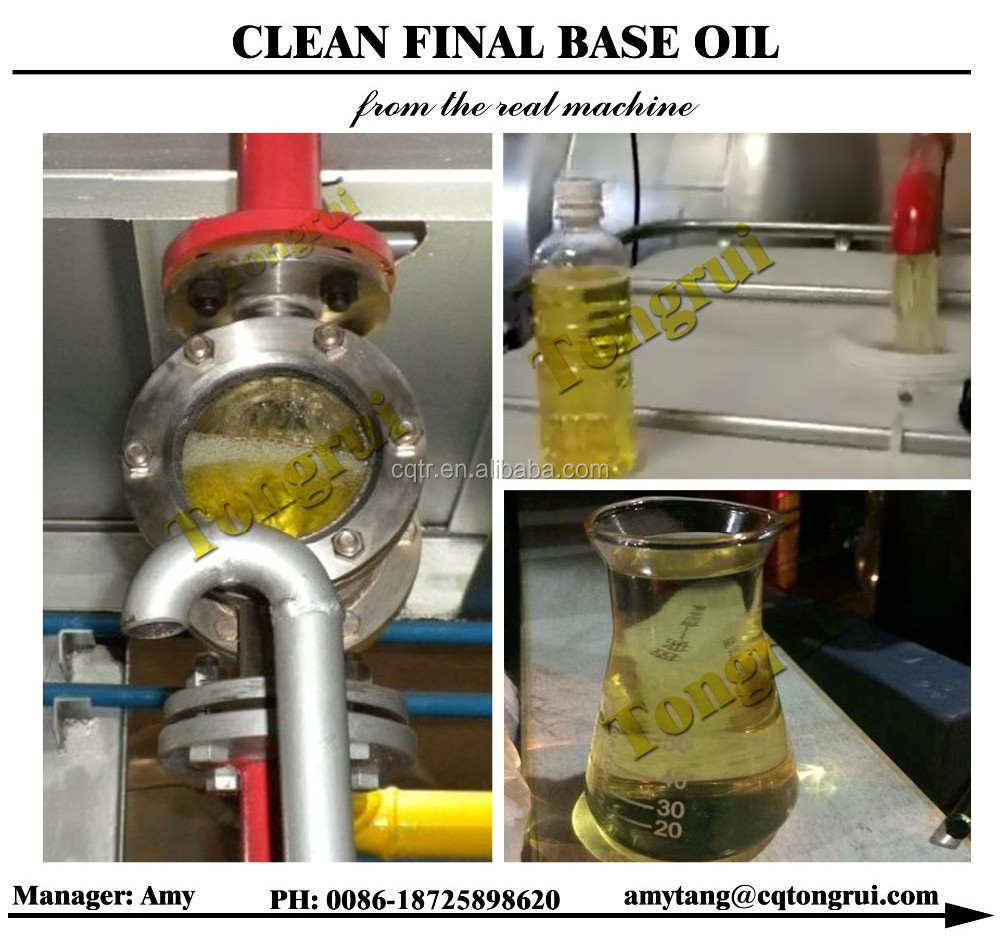

| The final oil test |

| Product advantage |

1. Easy to operate, low operation cost

2. Environmentally friendly, without secondary pollution.

3. The machine can recycle gasoline oil, diesel oil, engine oil, rubber oil and other lubricant oil to clean oil.

4. High quality refined oil, no any discoloration caused by oxidation, no any bad smelling.

5. Low cost contain:

1) only need the catalyst chemical, the cost is less than US$30 to refine one ton waste oil.

2) Heat consumption: 105kcal per ton waste oil

3) Power consumption: 40Kwh to recycle 1 ton waste oil

6. High degree of automation.

| Our service |

We provide many

free services

, such as:

1) engineer overseas service

2) Maintenance and replacement service, when it is necessary

3) tracking service for products for 12 months, lifetime service

4) lifetime technical assistant service.

5) old customer has more discount, or the customer introduce others to us, which has more discount.

6) Oil business plan suggestions

1.what ability we have?

mature technologies and skillful workmanship (we control every single manufacturing process and make sure

it will be done perfectly in our factory with the lowest cost with the best quality assurance). p

roducts quality guarantee and about 30 days free train(competitors cant spend much time in you factory,stay

long you will find many problems about their machine)

2.How to deal with the residue?

The final residue is semi solid and can be processed for manufacturing asphalt, or briquette for burn, or blend

with oil to make off-speck heavy fuel oil or to make greases for slow moving machineries.

3.Why we need to add the catalyst?

Catalyst will keep the recycled oil stabilization, avoiding the recycled oil oxidate and color change back to black.

So the recycled oil from our machine will keep yellow at least half one year or one year.

4.Why the machine need work under vacuum condition?

The machine work under negative pressure, the boiling rage of the used oil is lower under high vacuum

condition, if without vacuum unit, the oil will crack when temperature up to 420-450 degree( and the oil will

become to diesel when temperature is 450 degree)

| waste engine oil recycling machine to base oil | hydraulic oil/lubricant oil purifier to remove impurities and water | oxidized oil color remove machine( for bad color base oil, diesel, hydraulic oil, turbine oil |