- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JUBAO

-

Product Name:

-

Bulk bag unloader

-

Name:

-

big bag unloading station

-

Key Words:

-

Big Bag Discharge Machine

-

Application:

-

Powder, particle, small solid

-

Size:

-

Customized Size

-

Capacity load:

-

1-500T/heavy Load Capacity

-

Packing:

-

Wooden Case Packing

-

Function:

-

Dumping(or Tipping )

-

Type:

-

Atuomatic

-

Usage:

-

Heavy Duty

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

100

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JUBAO

-

Product Name:

-

Bulk bag unloader

-

Name:

-

big bag unloading station

-

Key Words:

-

Big Bag Discharge Machine

-

Application:

-

Powder, particle, small solid

-

Size:

-

Customized Size

-

Capacity load:

-

1-500T/heavy Load Capacity

-

Packing:

-

Wooden Case Packing

-

Function:

-

Dumping(or Tipping )

-

Type:

-

Atuomatic

-

Usage:

-

Heavy Duty

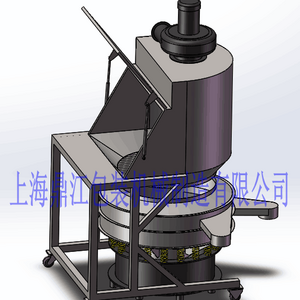

Products Description

1-500t/h dust-free bulk bag grain loading unloading

machine bulk bag dumping station

Bulk bag unloading station

is the discharging equipment of powder equipment. In order to facilitate transportation and storage, many raw materials are packaged by ton bag ,

bulk bag

, so bulk bag unloading station is extremely important in the whole production process. B

ulk bag unloading station

is also known as

bulk

bag unloader,

bulk

bag dismantling machine, in order to prevent the impact of dust on the environment and damage to the health of workers in the process of ton

bulk

bag opening, now most companies will use ton bulk bag unloading station when opening the bag.

The features of Bulk bag unloading station

1. To maintain a clean and safe working environment, bulk bag unloading stations often incorporate dust control and containment features.

2. Material Flow Regulation: Depending on the application and material properties, the unloading station may include mechanisms to regulate the flow of material from the bulk bag. This can involve flow control valves, adjustable discharge openings, or vibratory devices.

3. Safety Features: Bulk bag unloading stations prioritize operator safety. They may include safety interlocks, emergency stop buttons, or guarding systems to prevent accidents or injuries during operation. Some stations also incorporate safety sensors or alarms to detect bag misalignment, overpressure, or other potential hazards.

The picture below shows our conveying and packaging lines for chemical powder producers in Oman

.

Production process:

Use Spider-Lift bulk bag lifting frame to put the bulk bag into the

bulk bag unloading station

.

Then the material will be automatically transported to the filling/packing machine by the vacuum conveyor.

At this time, a worker is required to place the bag into the discharge port of the packing machine. Employees can observe the control system next to the packing machine, when the weight is 25kg or 50kg, press the stop filling button, and then the belt conveyor will transport the bag to the Automatic sewing machine/Heat sealing machine on the right for sealing.

If you want to design your production line or buy

bulk bag unloading station

,vacuum conveyor, packing machine and belt conveyor, please

contact us

today.

Detail display

Packaging & Shipping

Application

The equipment is mainly used in plastic, rubber, food, mineral, chemical, building materials, food, feed and other fields.

If you want to know more about product application, or consult smart powder solutions, please

contact us

.

Hot Searches