- Product Details

- {{item.text}}

Quick Details

-

Injection Rate (g/s):

-

170 g/s

-

Injection Weight (g):

-

370 g

-

Screw diameter (mm):

-

50 mm

-

Weight (KG):

-

9100 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

534 mm

-

Power (kW):

-

15 kW

Quick Details

-

Ejector Stroke(mm):

-

95 mm

-

Ejector Force(kN):

-

45 kN

-

Theoretical Shot Volume(cm³):

-

392 cm³

-

Injection Rate (g/s):

-

170 g/s

-

Injection Weight (g):

-

370 g

-

Screw diameter (mm):

-

50 mm

-

Weight (KG):

-

9100 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

534 mm

-

Power (kW):

-

15 kW

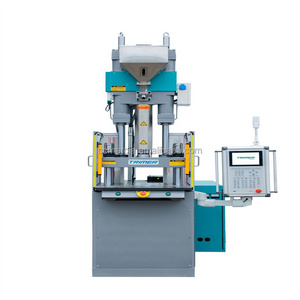

LSR vertical injection moulding hine-double sliding table

Machine's picture details as below

| V160SD-GII-LSR Technical Data Sheet Specification | ||||||

| INJECTION UNIT | Screw Diameter | mm | Φ50 | Φ55 | ||

| Theoretical Injection Volume | cm3 | 392 | 475 | |||

| Injection Rate | cm3/sec | 220 | 266 | |||

| Injection Speed | mm/s | 112 | 112 | |||

| Max.Injection Pressure | Mpa(kgf/cm2) | 176(1803) | 146(1490) | |||

| Screw Speed Rotation | r.p.m | 0~300 | ||||

| Nozzle Out From Platens | mm | 0-45 | ||||

| CLAMPING UNIT | Clamping Force | kN(tf) | 1568(160) | |||

| Clamping Stroke | mm | 300 | ||||

| Min.Mold Thickness | mm | 234(334) | ||||

| Max.Opening | mm | 534(634) | ||||

| Distance Between Tie Bars | mm | 860*420 | ||||

| Max Mould Size | mm | 550*550 | ||||

| Ejector Distance | mm | 95 | ||||

| Ejector Force | kN(tf) | 45(4.6) | ||||

| OTHERS | System Pressure | Mpa(kgf/cm2) | 13.7(140) | |||

| Oil Tank Capacity | L | 415 | ||||

| Electric Power | kW(HP) | 22.5(30) | ||||

| Machine Dimension | L*W | mm | 2296*2160 | |||

| H | mm | 3630(4530) | ||||

| Machine Weight | ton | 9.1 | ||||

2. We will arrange to manufacture the second day after confirmation,we can delivery it usually after 30 days

3. According to the destination,we will compare several transportation companies and select the most suitable and economic one to provide service for us

1. Provide free guidance of before you start use our plastic injection molding machine

2. 1 year warranty

3. Free r emote guidance by video chat when you have problem during use the injection molding machine