- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China, shenzhen

-

Brand Name:

-

JSX

-

Model Number:

-

JSX-wood

-

Processing Type:

-

Metal Cutting Tools

-

Usage:

-

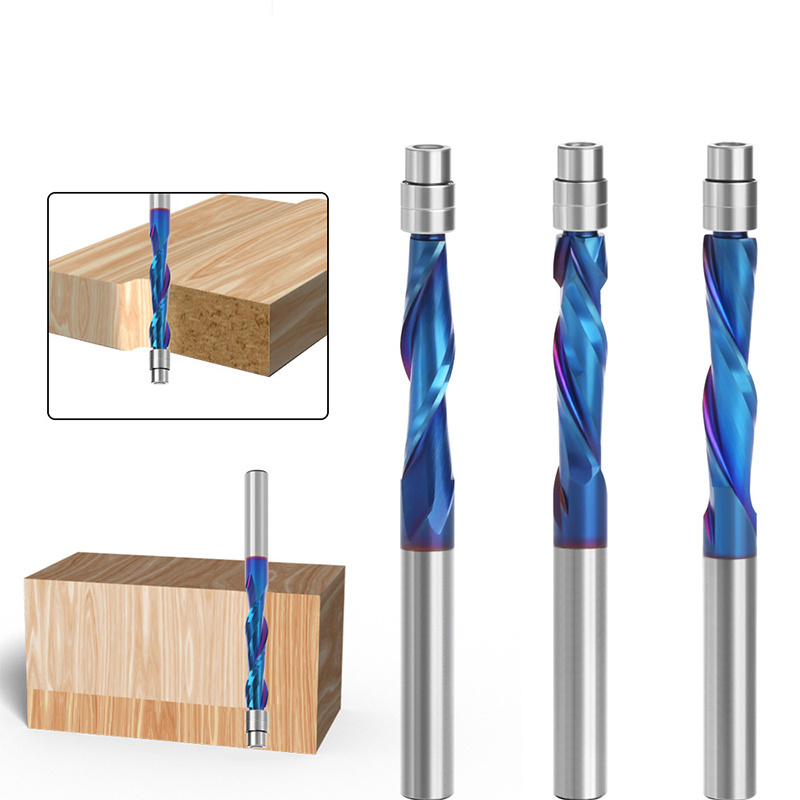

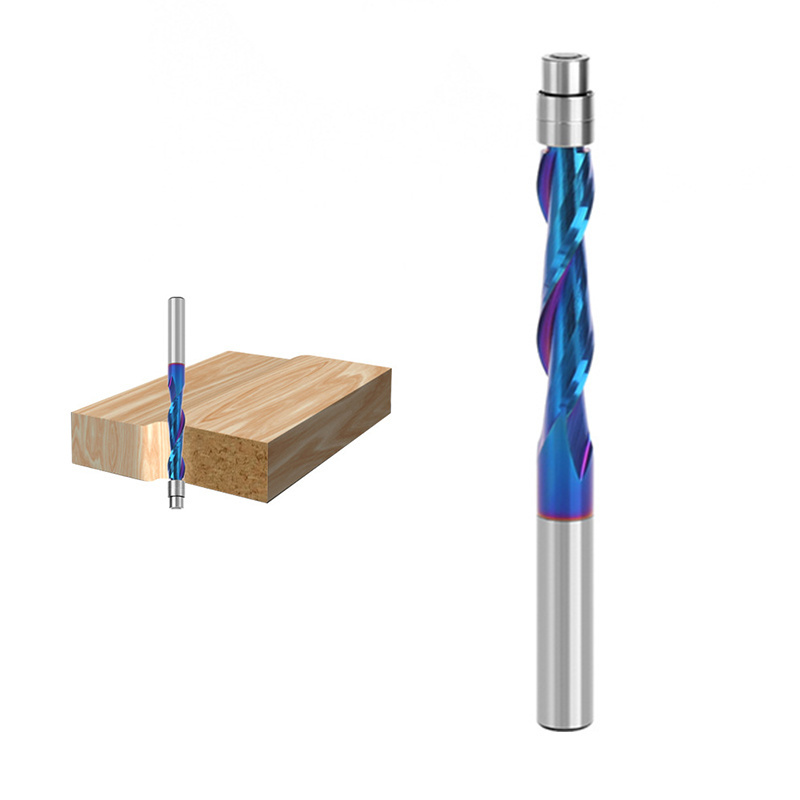

Woodworking

-

Precision:

-

High Precision

-

Application:

-

Furniture

-

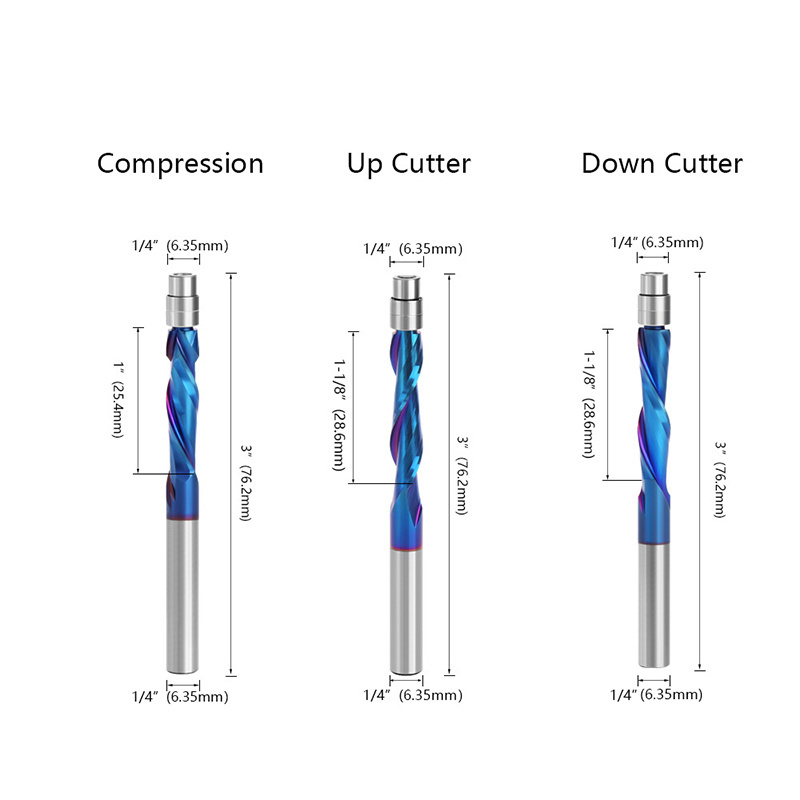

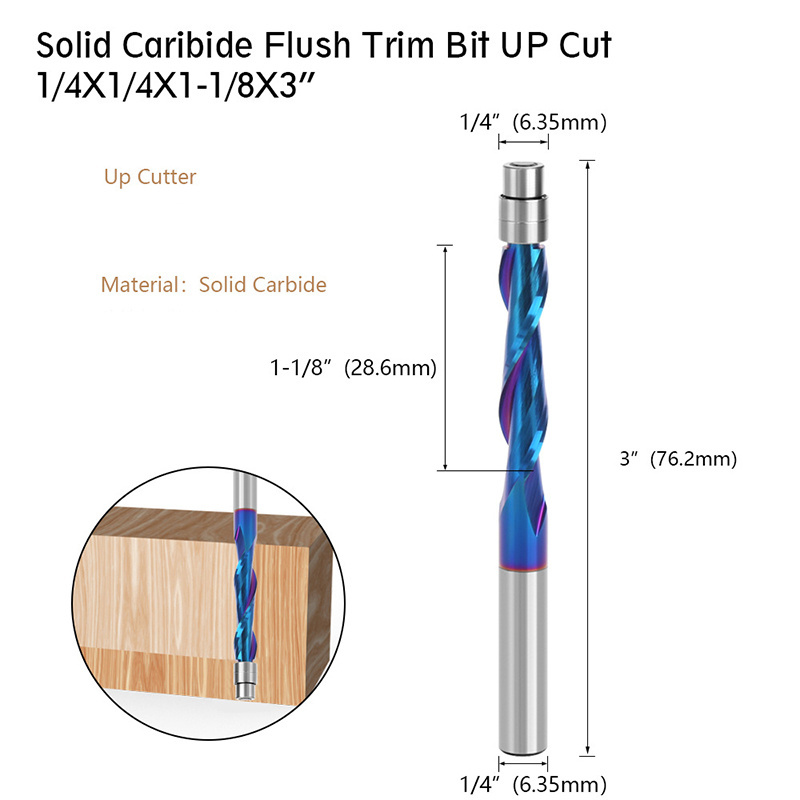

Shank Diameter:

-

1/4 inch 6.35mm

-

Type:

-

Miling Cutter

-

MOQ:

-

1 Pieces

Quick Details

-

Material:

-

Carbide

-

Coating:

-

uncoated

-

Warranty:

-

other

-

Place of Origin:

-

Guangdong, China, shenzhen

-

Brand Name:

-

JSX

-

Model Number:

-

JSX-wood

-

Processing Type:

-

Metal Cutting Tools

-

Usage:

-

Woodworking

-

Precision:

-

High Precision

-

Application:

-

Furniture

-

Shank Diameter:

-

1/4 inch 6.35mm

-

Type:

-

Miling Cutter

-

MOQ:

-

1 Pieces

Product Description

|

Model Number

|

JSX-wood

|

|

Material

|

Carbide

|

|

Coating

|

uncoated

|

|

Controlling Mode

|

High Speed Cutting

|

|

Usage scenarios

|

Mixed Wood shaving board

|

|

Processing Type

|

nonmetal

|

|

Application

|

Furniture

|

|

Usage

|

General

|

|

Precision

|

High Precision

|

|

Machine Type

|

Milling Machine

|

Details Images

skill:

1.All tools are designed to rotate clockwise to avoid breaking under excessive pressure.

2. All the cutting tools shall pass the balance test at the completion of production to ensure that there is no doubt of

diameter jump. In order to again ensure that the cutting tools do not swing and skip in use, please pay attention to the

selection of appropriate mechanical equipment and excellent jacket.

3 The jacket must be selected the appropriate size, if it is found that the jacket is not round enough or wear, it will lead to

the jacket can not be normal and correct clamping tool, please immediately replace the intact jacket with standard specifications,

to avoid the tool in high-speed rotation under the vibration of the handle, and then the risk of flying off or broken.

4.The tool shank shall be installed in accordance with EU regulations. For example, the grip depth of 12.7 mm must be 24mm to

maintain the proper pressure range of the tool shank.

5.Setting of speed: The tool with large outside diameter should be set in accordance with the following tachometer, and slowly

advance, maintain a uniform advancing speed, do not stop the advancing action in the cutting process.

Suggested Router Speeds

Bit Diameter Maximum speed

1 "(25 mm) 24,000 RPM

1-1/4 "-2(30-50 mm) 18,000 RPM

2-1/4 "-2-1/2(55-65 mm) 16,000 RPM

3 "-3-1/2(75-90 mm) 12,000 RPM

6.When the tool is blunt, please replace the new tool, do not continue to use, in order to avoid tool breakage and industrial

injury.

7.When using a tool, please choose a tool with a blade length greater than the workepiece. For example, if you want to mill a

groove with a depth of 12.7 mm, please choose a tool with a blade length of 25.4 mm. Avoid using a tool with a blade length equal to

or less than 12.7 mm.

8.When processing, please wear safety glasses and push handle safely. It is also needed when using desktop mechanical devices

2. All the cutting tools shall pass the balance test at the completion of production to ensure that there is no doubt of

diameter jump. In order to again ensure that the cutting tools do not swing and skip in use, please pay attention to the

selection of appropriate mechanical equipment and excellent jacket.

3 The jacket must be selected the appropriate size, if it is found that the jacket is not round enough or wear, it will lead to

the jacket can not be normal and correct clamping tool, please immediately replace the intact jacket with standard specifications,

to avoid the tool in high-speed rotation under the vibration of the handle, and then the risk of flying off or broken.

4.The tool shank shall be installed in accordance with EU regulations. For example, the grip depth of 12.7 mm must be 24mm to

maintain the proper pressure range of the tool shank.

5.Setting of speed: The tool with large outside diameter should be set in accordance with the following tachometer, and slowly

advance, maintain a uniform advancing speed, do not stop the advancing action in the cutting process.

Suggested Router Speeds

Bit Diameter Maximum speed

1 "(25 mm) 24,000 RPM

1-1/4 "-2(30-50 mm) 18,000 RPM

2-1/4 "-2-1/2(55-65 mm) 16,000 RPM

3 "-3-1/2(75-90 mm) 12,000 RPM

6.When the tool is blunt, please replace the new tool, do not continue to use, in order to avoid tool breakage and industrial

injury.

7.When using a tool, please choose a tool with a blade length greater than the workepiece. For example, if you want to mill a

groove with a depth of 12.7 mm, please choose a tool with a blade length of 25.4 mm. Avoid using a tool with a blade length equal to

or less than 12.7 mm.

8.When processing, please wear safety glasses and push handle safely. It is also needed when using desktop mechanical devices

Hot Searches