- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.5Mpa(25mm thickness)

-

Density (kg/m³ ):

-

128

-

Length:

-

7200mm/3600mm(7320mm/3660mm)

-

Working Temperature:

-

1000°C

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

-3%

-

Thermal Conductivity:

-

0.06-0.12

-

Model Number:

-

ceramic fiber blanket

-

Brand Name:

-

Snder

-

Place of Origin:

-

Shandong, China

-

Usage:

-

Refractory Application

-

Name:

-

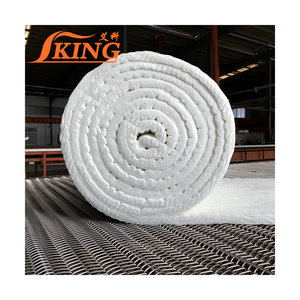

Pure White Ceramic Wool Blanket

-

Color:

-

Pure White

-

Product name:

-

ceramic fiber blanket

-

Type:

-

Insulation Fireproof Material Fireplace

-

Classification Temperature:

-

1260/1260/1350/1430

-

Certificate:

-

ISO9001:2000

-

Package:

-

Carton

-

Application of ceramic fiber blanket:

-

Electricity Boilers

-

Raw material:

-

Spuned Ceramic Fiber Bulk

Quick Details

-

Thickness:

-

6mm-50mm

-

Width:

-

100mm-1220mm

-

Chemical Composition:

-

AL2O3+SIO2≥99%

-

Ultimate Strength (≥ MPa):

-

0.5Mpa(25mm thickness)

-

Density (kg/m³ ):

-

128

-

Length:

-

7200mm/3600mm(7320mm/3660mm)

-

Working Temperature:

-

1000°C

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

-3%

-

Thermal Conductivity:

-

0.06-0.12

-

Model Number:

-

ceramic fiber blanket

-

Brand Name:

-

Snder

-

Place of Origin:

-

Shandong, China

-

Usage:

-

Refractory Application

-

Name:

-

Pure White Ceramic Wool Blanket

-

Color:

-

Pure White

-

Product name:

-

ceramic fiber blanket

-

Type:

-

Insulation Fireproof Material Fireplace

-

Classification Temperature:

-

1260/1260/1350/1430

-

Certificate:

-

ISO9001:2000

-

Package:

-

Carton

-

Application of ceramic fiber blanket:

-

Electricity Boilers

-

Raw material:

-

Spuned Ceramic Fiber Bulk

Fire Resistant Blanket Heat Insulation Aluminum Silicate Ceramic Riber Blanket

Product Description

Snderwool blanket

Snder wool blanket is high strength, needled insulating blanket that is made from Snderwool bulk. The combination of long spun fibers and needling operation produce tough, resilient and strong blankets, which resist tearing both before and after heating. Snderwool blanket is completely inorganic and available in a variety of temperature grades, densities and sizes. Snderwool blanket can be folded, compressed and encapsulated to produce modules.

Features

Features of Snderwool blanket :

1) Excellent thermal shock resistance

2) Excellent thermal stability

3) High tensile strength

4) Low thermal conductivity

5) Low heat storage

2) Excellent thermal stability

3) High tensile strength

4) Low thermal conductivity

5) Low heat storage

Typical Parameters

|

Description

|

SNDERWOOL STD BLANKET

|

|

|

SNDERWOOL HP BLANKET

|

|

SNDERWOOL HA BLANKET

|

|

SNDERWOOL HZ BLANKET

|

|

|||||||||

|

Classification Temperature(℃)

|

1260

|

|

|

1260

|

|

1260

|

|

1430

|

|

|||||||||

|

Chemical Composition (%)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Al2O3

|

≥43

|

|

|

≥44

|

|

≥52

|

|

≥35

|

|

|||||||||

|

SiO2

|

≥54

|

|

|

≥55

|

|

≥47

|

|

≥49

|

|

|||||||||

|

ZrO2

|

-

|

|

|

-

|

|

-

|

|

-

|

|

|||||||||

|

Color

|

White

|

|

|

White

|

|

White

|

|

White

|

|

|||||||||

|

Shot Content (%)

|

≤15

|

|

|

≤15

|

|

≤15

|

|

≤12

|

|

|||||||||

|

Density(kg/m³)

|

64

|

96

|

128

|

96

|

128

|

96

|

128

|

96

|

128

|

|||||||||

|

Tensile Strength (kPa)

|

30

|

50

|

70

|

50

|

70

|

50

|

70

|

50

|

70

|

|||||||||

|

Permanent Linear Shrinkage(%)

|

1000℃ x24h≤2.5

|

|

|

1100℃ x24h≤2.5

|

|

1200℃ x24h≤3.0

|

|

1350℃ x24h≤3.0

|

|

|||||||||

|

Thermal Conductivity (W/m*K)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

200℃

|

0.07

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

|||||||||

|

400℃

|

0.12

|

0.11

|

0.11

|

0.11

|

0.10

|

0.11

|

0.10

|

0.11

|

0.10

|

|||||||||

|

600℃

|

0.20

|

0.19

|

0.19

|

0.19

|

0.17

|

0.18

|

0.16

|

0.16

|

0.15

|

|||||||||

|

800℃

|

0.30

|

0.23

|

0.23

|

0.23

|

0.20

|

0.22

|

0.20

|

0.21

|

0.19

|

|||||||||

|

1000℃

|

0.40

|

0.32

|

0.31

|

0.31

|

0.26

|

0.30

|

0.26

|

0.30

|

0.26

|

|||||||||

Typical Applications

Typical Applications of Snderwool blanket:

1)Ceramic industry:

Kiln car insulation and seals

Continuous and batch kilns

2)Steel industry:

Heat treating and annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Furnace hot face repairs

Reheating furnace and ladle covers

3)Refining and petrochemical industry:

Reformer and pyrolysis lining

Tube seals,gaskets and expansion joints

High temperature pipe,duct and turbine insulation

Crude oil heater linings

Other typical application:

Industry furnace wall lining

Kiln car insulation and seals

Continuous and batch kilns

2)Steel industry:

Heat treating and annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Furnace hot face repairs

Reheating furnace and ladle covers

3)Refining and petrochemical industry:

Reformer and pyrolysis lining

Tube seals,gaskets and expansion joints

High temperature pipe,duct and turbine insulation

Crude oil heater linings

Other typical application:

Industry furnace wall lining

Back lining material

Fire prevention

High-temperature tube heat insulation material

Module/folding block processing material

Filling and sealing material in high temperature environment

*Sound-absorbing or high temperature filtration materials

*Sound-absorbing or high temperature filtration materials

Packing & Delivery

Shipping

1. FEDEX/DHL/UPS/TNT/EMS or shipped by Alibaba parcel for samples.

2. By Sea for batch goods.

3. Customers specify freight forwarders or negotiate shipping methods!

4. Delivery Time: 3-15 days for common shape samples, 7-45 days for batch goods.

1. FEDEX/DHL/UPS/TNT/EMS or shipped by Alibaba parcel for samples.

2. By Sea for batch goods.

3. Customers specify freight forwarders or negotiate shipping methods!

4. Delivery Time: 3-15 days for common shape samples, 7-45 days for batch goods.

Hot Searches