- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

victory

-

name:

-

prestressed concrete partition wallpanel moulding machine

-

color:

-

yellow, red,any color

-

Brick Raw Material:

-

cement, flyash

-

Method:

-

mechinical Extruder

-

model:

-

JQT10*60 prestressed concrete partition wallpanel making machine

-

Hole:

-

3pcs

-

width:

-

595+-2mm

-

thickness:

-

10+-1mm

-

market:

-

africa, asia

Quick Details

-

Weight (KG):

-

1000

-

Marketing Type:

-

Hot Product 2024

-

Core Components:

-

engine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

victory

-

name:

-

prestressed concrete partition wallpanel moulding machine

-

color:

-

yellow, red,any color

-

Brick Raw Material:

-

cement, flyash

-

Method:

-

mechinical Extruder

-

model:

-

JQT10*60 prestressed concrete partition wallpanel making machine

-

Hole:

-

3pcs

-

width:

-

595+-2mm

-

thickness:

-

10+-1mm

-

market:

-

africa, asia

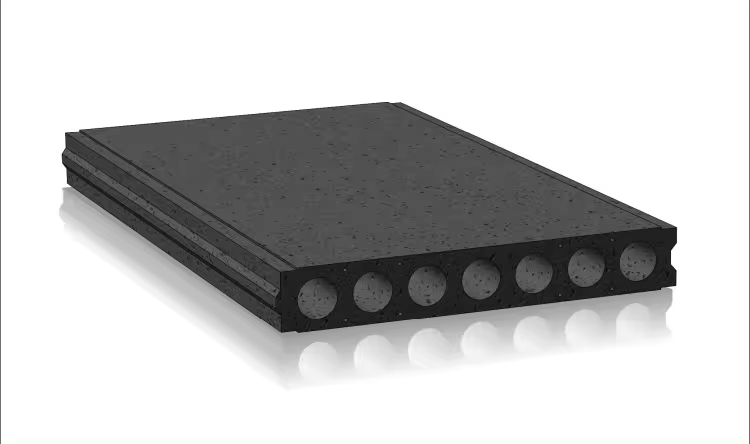

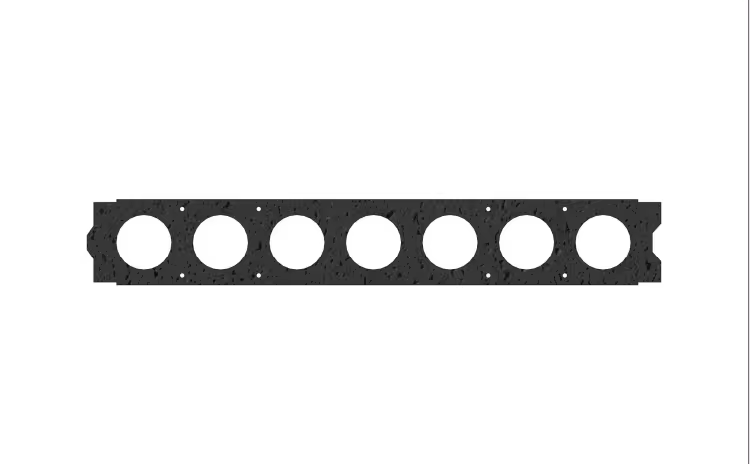

prestressed hollow core slab making machinery precast concrete wall panel machine brick

Product Features

|

Item

|

Thickness of plate (mm)

|

|

|

|

|

90

|

120

|

|

|

Shock resistance (times)

|

≥5

|

≥5

|

|

|

Single point hanging force ( N )

|

≥1000

|

≥1000

|

|

|

Bending failure load ( Plate weight multiple)

|

≥1.5

|

≥1.5

|

|

|

Drying shrinkage value ( mm/m)

|

≤0.6

|

≤0.6

|

|

|

Fire endurance ( h)

|

≥1

|

≥1

|

|

|

Compression strength ( Mpa)

|

≥3.5

|

≥3.5

|

|

|

Heat transfer [ W(m

2

.K)]

|

–

|

≤2.0

|

|

|

Coefficient of softing

|

≥0.8

|

≥0.8

|

|

|

Rate of water content ( %)

|

≤12/10/8

|

|

|

Concrete wall panel board concrete block making machine

FAQ for precast concrete wall panel machine:

Question 1. What is the Standard Size of Wall panel machine

For Precast Light weight Wall panel machine, JQT7.5*60 and JQT9*60 is more Standard all over the world ( 75mm thickness, 600mm width etc.)

Question 2. How Much Sqm will be installed 1 day?

Very quickly by Our Wall panel Installer (450sqm/day)

Question 3. Can we use wall panel as Exterior and interior Wall?

Yes, Can be used for both. (Exterior can be Double Layer Holes. Interior can use 9*60 or 7.5*60)

Question 4. How To Order From "Henan Victory Industrial co. ltd."?

Confirm PI (Profroma Invoice) with our sales Man

Payment: 50% deposit, the Balance 50% paid against Bill Of Lading Copy. (Old Customer: 30% &70%)