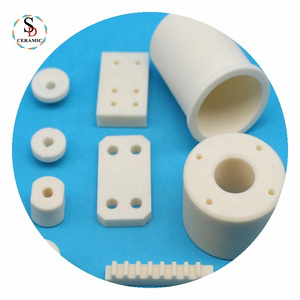

We can produce different sizes and shapes of the sheets for specific applications to different custom products.Such as drilling,polishing,stripes,concave and convex, screw holes, metal parts position and so on

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

xtl

-

Fit Tolerance::

-

+-0.005mm

-

Density:

-

3.8g/cm3

-

Product Name:

-

ceramic plunger

-

Shape:

-

As Drawing Requests

-

Color:

-

White&Light Yellow

-

Usage:

-

Wear-resisting Material

-

Package:

-

Individual Safe Packing

-

Max Working Temperature:

-

1650°C /1700°C

-

Feature:

-

High Wear-resistance,High Temperature Resistance

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Hunan, China

-

Model Number:

-

2021070-01

-

Brand Name:

-

xtl

-

Fit Tolerance::

-

+-0.005mm

-

Density:

-

3.8g/cm3

-

Product Name:

-

ceramic plunger

-

Shape:

-

As Drawing Requests

-

Color:

-

White&Light Yellow

-

Usage:

-

Wear-resisting Material

-

Package:

-

Individual Safe Packing

-

Max Working Temperature:

-

1650°C /1700°C

-

Feature:

-

High Wear-resistance,High Temperature Resistance

Manufacturing Technique

Produce and machining

:

Application

These are typically used in jet pumps, water jetting pumps, high pressure pumps and high pressure

water supply pumps, which find tremendous applications in industries including automobiles, chemical

and petrochemicals, foundries, oil refineries, paper and pulp manufacture, cement manufacturing, food

processing, thermal power plants and steel plants etc.

water supply pumps, which find tremendous applications in industries including automobiles, chemical

and petrochemicals, foundries, oil refineries, paper and pulp manufacture, cement manufacturing, food

processing, thermal power plants and steel plants etc.

Features of ceramic:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

We can do OEM and OBM according to you drawing and requires

|

Properties

|

Units

|

95 Alumina

|

99 Alumina

|

|

Density

|

g / cm³

|

3.65

|

3.92

|

|

Water absorption

|

%

|

0

|

0

|

|

Coefficient of thermal expansion

|

10-6/K

|

7.9

|

8.5

|

|

Modulus of Elasticity Young's Mod

|

GPa

|

280

|

340

|

|

Poisson's ratio

|

/

|

0.21

|

0.22

|

|

HV Hardness HV

|

MPa

|

1400

|

1650

|

|

Flexural Strength @ room temperature

|

MPa

|

280

|

310

|

|

Flexural Strength @700°C

|

MPa

|

220

|

230

|

|

Compressive Strength @ room temperature

|

MPa

|

2000

|

2200

|

|

Fracture Toughness

|

MPa *m 1/2

|

3.8

|

4.2

|

|

Heat conductivity @ room temperature

|

W/ m*k

|

18-25

|

26-30

|

|

Max use temperature

|

°C

|

1500

|

1750

|

|

Resistance to acid alkaline

|

/

|

high

|

high

|

|

Dielectric Constant

|

/

|

9.5

|

9.8

|

|

Dielectric Strength

|

KV/mm

|

16

|

22

|

|

Thermol Shock Resistance

|

△ T ( °C )

|

220

|

180-200

|

|

Tensile Strength @ 25 °C

|

MPa

|

200

|

248

|

Products Description

Product packaging

Certifications

Recommend Products

Hot Searches