- Product Details

- {{item.text}}

Quick Details

-

Ink Type:

-

LED-UV ink

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

MYJET

-

Voltage:

-

220V

-

Dimensions(L*W*H):

-

1550mm*1860mm*980mm

-

Weight:

-

200 KG

-

Marketing Type:

-

Hot Product 2023

-

Warranty of core components:

-

It depends

-

Product name:

-

MYJET 6090

-

Print head:

-

I3200

-

Printing Size:

-

60*90cm

-

Key words:

-

Phone Case Printing Machine

-

Ink:

-

UV Ink

-

Application:

-

Phone Case

-

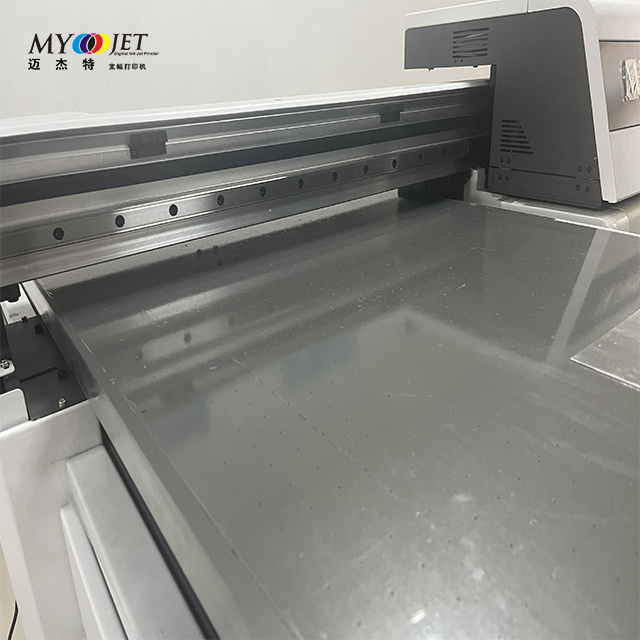

Media Type:

-

Flatbed Materials

-

Ink Color:

-

CMYKWV

-

Software:

-

Photoprint/Riprint

Quick Details

-

Print Dimension:

-

600mm, 600mm*600mm, 600mm*900mm

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Ink Type:

-

LED-UV ink

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

MYJET

-

Voltage:

-

220V

-

Dimensions(L*W*H):

-

1550mm*1860mm*980mm

-

Weight:

-

200 KG

-

Marketing Type:

-

Hot Product 2023

-

Warranty of core components:

-

It depends

-

Product name:

-

MYJET 6090

-

Print head:

-

I3200

-

Printing Size:

-

60*90cm

-

Key words:

-

Phone Case Printing Machine

-

Ink:

-

UV Ink

-

Application:

-

Phone Case

-

Media Type:

-

Flatbed Materials

-

Ink Color:

-

CMYKWV

-

Software:

-

Photoprint/Riprint

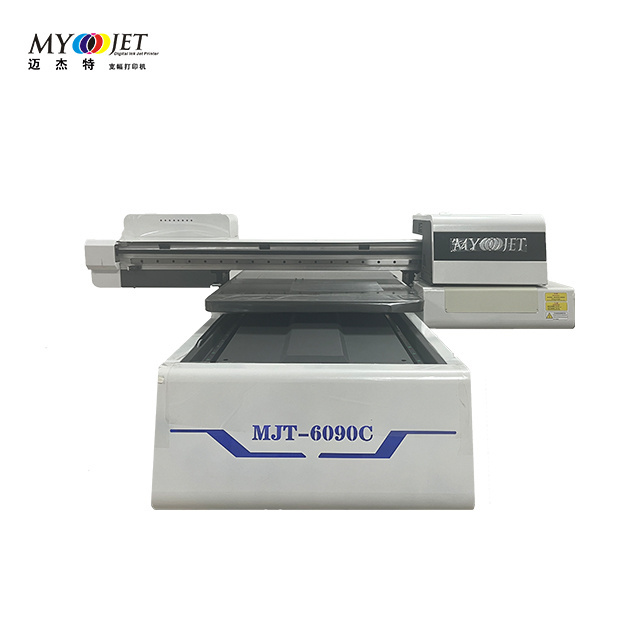

MYJET UV6090 INKJET PRINTER

| Model | Technical Parameter | |||

| MYJET-6090 | Type of Printheads | EPSON i3200-U1 3 unit | ||

| Maximum print size | 610mm*910mm | |||

| Printing Precision | 720*720 720*1080 720*1440 720*2160 | |||

|

Printing Speeds

|

Draft model

|

7 minutes 51 seconds 73 | ||

|

Production model

|

12 minutes 15 seconds 50 | |||

|

Precision model

|

15 minutes 46 seconds 01 | |||

| Ink Supply | Positive pressure for ink | |||

| Curing Mode/Ink Type | High power LED water cooled UV lamp /UV curable ink | |||

| Control System | Hoson system | |||

| Data interface | Network | |||

| Rip Software | RIprint / Photoprint | |||

| Ink Cartridge Volume | 1.5L | |||

| Computer Config | Intel i7-7 and Above, USB3.0, Gigabit Ethernet, 8G RAM, SS | |||

| Power | 1600W | |||

| Machine Dimension |

Machine size :1550*1860*980mm; Packing size :3600*980*1490mm |

|||

| Net Weight/Gross Weight | 180kg/280kg | |||

| The Operating Environment |

Temperature equipment operating 15℃-30℃ (recommended 20℃-28℃)

Humidity equipment 20%-80% (recommended 40%-60%) |

|||

| The Printing Material | Signs, crafts, gift boxes, toys, etc. | |||

About us:

Developed from Kanger Image Equipment Co., Ltd, Shanghai Xinan International Trading Co. Ltd successively has cooperated with British XAAR, Japanese Konica and American FUJI FILM DIMATIX. We have formed a strong strategic cooperation alliance, and kept developing advanced inkjet technology,

which makes us become the leader in the advertising industry quickly.

Till now, We created 3 series brands, MYJET, DIE CAI and SAI DI. And we have built the first level distribution network in more than 20 regions of China and 40 countries of the world We have passed ISO9001 and CE authentication, which laid a strong foundation for the 20 years global stratagems.

MYJET digital ink jet printer has won a very good praise by the public. It is recognized to be the most stable and famous brand of digital inkjet printers, which satisfied customers with the best quality and the most considerate service. We have at tended American ISA Exhibition, Shanghai International Sign Show, European Sign Show and Dubai Sign Graphic lmaging Show.

We will continue to adopt the advanced technology of the world in inkjet printing industry.

We decide to build the Chinese top level products! MYJET- prints superb images for vision world!

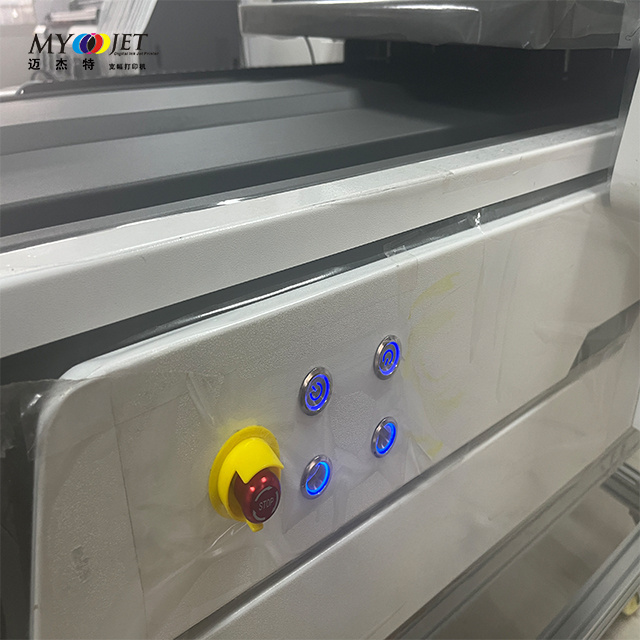

1. A single nozzle can not be made out of ink?

Replacing the nozzle, replacing the sprinkler data line or the nozzle switch board, inserting the data line of the nozzle, repairing the ink supply system, and replacing the main plate.

2. All the spray heads are not out of ink?

Repair the power, replace the head card, replace the main board. Reinstall or replace the decoder, reinsert or replace the fiber line.

3. Broken line?

Improve the temperature of the environment, adjust the voltage of the nozzle, clean the nozzle with the cleaning liquid and replace the ink.

4. Unable to discharge material?

Replacement of photoelectric switch, replacement of discharge motor or rewiring.

5. Middle wrinkle when printing?

Re feed, adjust the parallelism of the feed wheel and the feed wheel shaft, and adjust the pressure of the press wheel.

6. No moving head or software part function can't be used?

Replacement of main board, rewiring, reconnection or replacement of driver, replacement of motor or rewiring.

7. Stop printing?

Replace the decoder and grating, adjust the position of the decoder to the middle of the decoding bar, replace the motor, on change the material to the small volume.

8. Inability to provide ink?

Replace the cartridge inductor, replace or reconnect, replace the main board, replace the ink pump, and replace the filter.

9. For ink supply?

Replacement of the main board and rewiring.

10. The print test bar and the diagram are not normal?

Change the grating or decoder, reconnect the fiber line, replace the driver, and replace the main board.