- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

elaiter

-

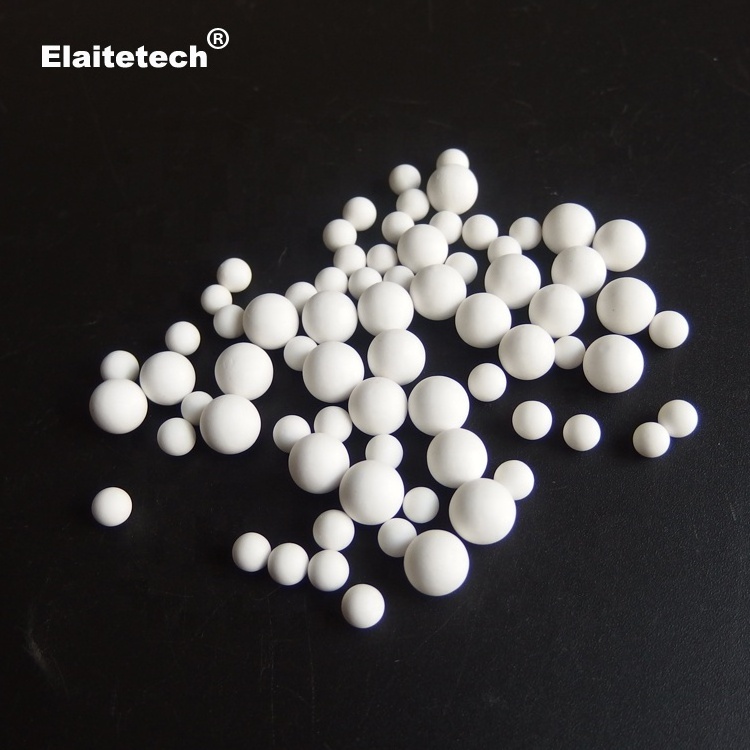

Size:

-

1mm-90mm

-

Usage:

-

Grinding, dispersing, polishing

-

Color:

-

White

-

Shape:

-

Ball

-

Al2O3 content:

-

70-95%

-

Water Absorption:

-

≤0.01%

-

Bulk density:

-

3-3.6g/cm3

-

Moh's Hardness:

-

7-9

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Guangxi, China

-

Model Number:

-

ELT-AGB

-

Brand Name:

-

elaiter

-

Size:

-

1mm-90mm

-

Usage:

-

Grinding, dispersing, polishing

-

Color:

-

White

-

Shape:

-

Ball

-

Al2O3 content:

-

70-95%

-

Water Absorption:

-

≤0.01%

-

Bulk density:

-

3-3.6g/cm3

-

Moh's Hardness:

-

7-9

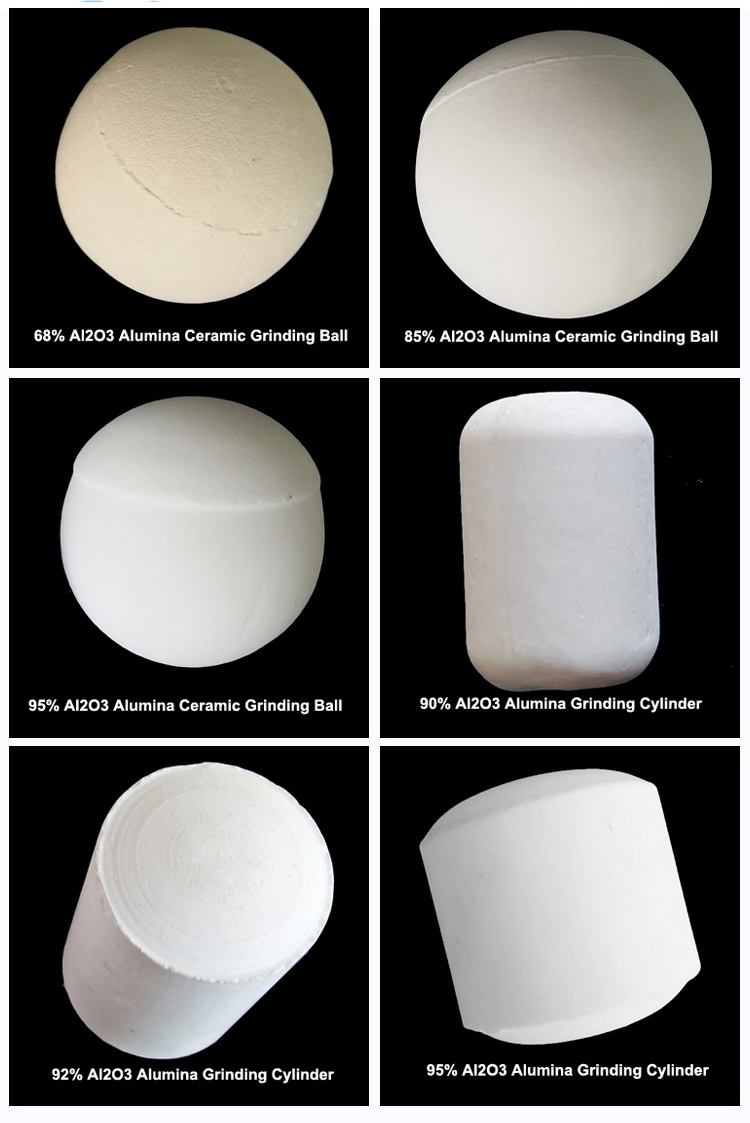

Alumina grinding ball is an economical, widely-used and non-metallic grinding media; it has high strength, high hardness, high wear resistance, high temperature resistance, corrosion resistance and other excellent characteristics, and so can improve grinding efficiency and keep no contamination to your product.

1. Clay grinding for ceramic tile manufacturing.

2. Glaze grinding.

3. Paint grinding.

4. Quartz grinding.

5. Pigment grinding.

1. High purity, no effect on the quality of the grinded materials.

2. High density, can save grinding time, expand grinding space, and improve the effect of grinding.

3. Low abrasion loss, can greatly prolong the service life of the grinding ball.

4. High temperature resistance, acid and alkali resistance and corrosion resistance.

|

Item |

70 Series |

75 Series |

85 Series |

90 Series |

92 Series |

95 Series |

|

Al 2 O 3 content (%) |

≥68 |

≥75 |

≥85 |

≥90 |

≥ 92 |

≥95 |

|

Water absorption (%) |

≤0.02 |

≤ 0.02 |

≤0.02 |

≤0.02 |

≤0.01 |

≤0.01 |

|

Bulk density (g/cm 3 ) |

≥ 3.0 |

≥ 3.2 |

≥3.4 |

≥3.5 |

≥3.6 |

≥3.65 |

|

Moh's hardness (Scal) |

7-8 |

8 |

9 |

9 |

9 |

9 |

|

Crushing strength (Mpa) |

≥1600 |

≥1700 |

≥1800 |

≥1900 |

≥2000 |

≥2250 |

|

Abrasion loss (%) |

≤0.03 |

≤ 0.02 |

≤0.015 |

≤0.013 |

≤0.012 |

≤0.01 |

|

Color |

Yellowlsh |

White |

White |

White |

White |

White |

|

Size |

Tolerance (mm) |

|||||

|

70 Series |

75 Series |

85 Series |

90 Series |

92 Series |

95 Series |

|

|

Φ1-Φ15mm |

±0.5 |

±0.5 |

±0.5 |

±0.5 |

±0.5 |

±0.5 |

|

Φ16-Φ25mm |

±1 |

±1 |

±1 |

±1 |

±1 |

±1 |

|

Φ30-Φ40mm |

±1.5 |

±1.5 |

±1.5 |

±1.5 |

±1.5 |

±1.5 |

|

Φ50-Φ60mm |

±2 |

±2 |

±2 |

±2 |

±2 |

±2 |

|

Φ70-Φ80mm |

±3 |

±3 |

±3 |

±3 |

±3 |

±3 |

|

Φ90mm |

±3.5 |

±3.5 |

±3.5 |

±3.5 |

±3.5 |

±3.5 |

|

Note: Φ1-Φ25mm formed by rolling molding; Φ30-Φ80mm formed by isostatic pressing. |

||||||