Independent research and development adopts servo + CCM silent linear sliding table bag pulling technology to make the

packaging more flat and the bag length accurate.

It can be equipped with photoelectric control device to ensure the integrity of the packaging bag pattern.304 stainless steel is used for the whole contact material parts and the casing, which conforms to the food and drug hygienic licensing standards. Packaging process: film sterilization, bag making, date printing, filling, sealing, cutting, and counting can be done at one time

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1

-

Voltage:

-

220v/AC 50Hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

mingyuan

-

Dimension(L*W*H):

-

1050*850*2050mm

-

Weight:

-

370 KG

-

bag-making length:

-

50-150mm

-

bag-making width:

-

65-150mm

-

Packing capacity:

-

50-550ml

-

Packing film width:

-

150-320mm

-

Packing speed:

-

1100-1300bags/h

-

Marketing Type:

-

New Product 2022

Quick Details

-

Machinery Capacity:

-

200BPH, Other

-

Packaging Material:

-

Plastic, Paper

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Other

-

Filling Accuracy:

-

1

-

Voltage:

-

220v/AC 50Hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

mingyuan

-

Dimension(L*W*H):

-

1050*850*2050mm

-

Weight:

-

370 KG

-

bag-making length:

-

50-150mm

-

bag-making width:

-

65-150mm

-

Packing capacity:

-

50-550ml

-

Packing film width:

-

150-320mm

-

Packing speed:

-

1100-1300bags/h

-

Marketing Type:

-

New Product 2022

Products Description

|

Model

|

MY-ZF1000

|

|

|

|

|||

|

Bag Length

|

50-150mm

|

|

|

|

|||

|

Bag Width

|

65-150mm

|

|

|

|

|||

|

Film Width

|

150-320mm

|

|

|

|

|||

|

Bag Capacity

|

50-500ml

|

|

|

|

|||

|

Packing speed

|

19-22bags/min

|

|

|

|

|||

|

Power

|

220V/AC 50Hz 2.1Kw

|

|

|

|

|||

|

Machine size

|

1050*850*2050mm

|

|

|

|

|||

|

Machine weight

|

370kg

|

|

|

|

|||

|

Sealing type

|

back sealing

|

|

|

|

|||

Selling point of a product

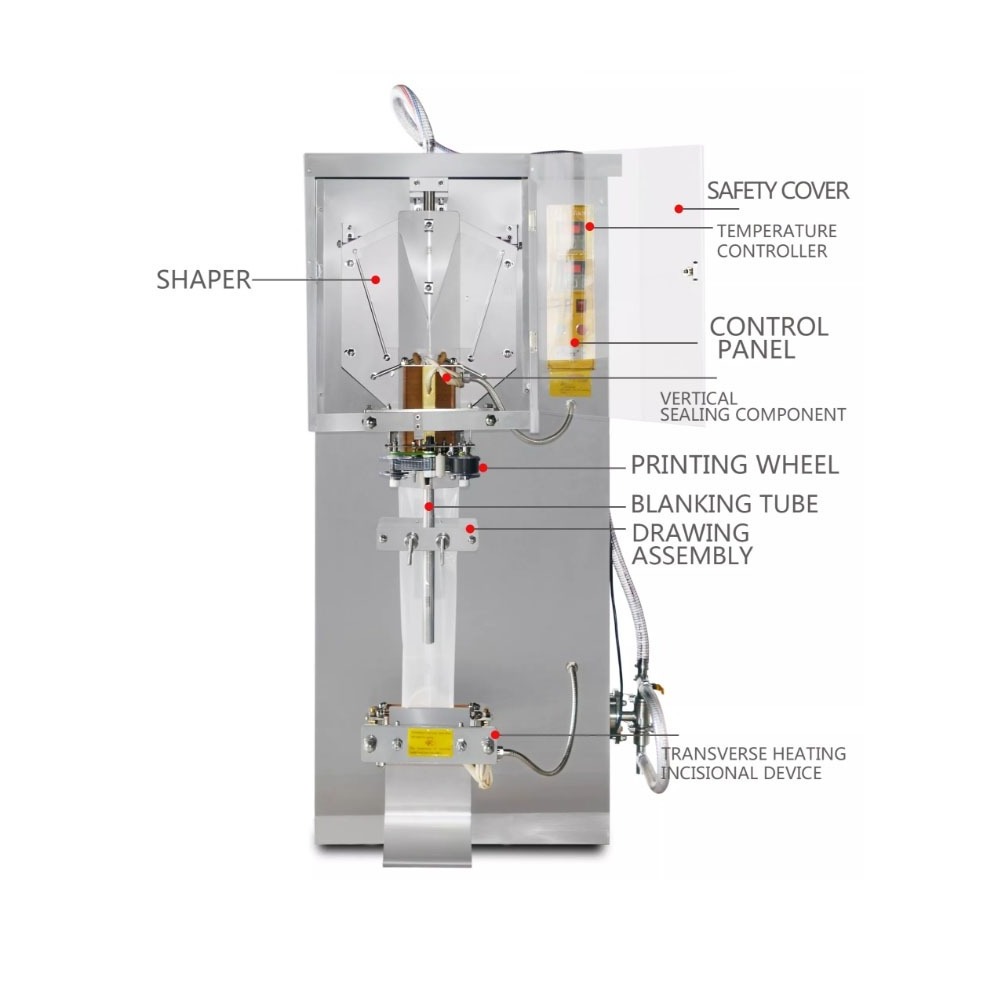

Operation panel detail display

Operation panel (intelligent version): Adopt PLC controller with color touch screen, support multiple languages, all working parameters can be set and reflected on the control panel, easy to operate

liquid Metering Pump

Connect the liquid tank , liquid metering pump with check valve toquickly measure the same liquid volume to absorb and pack.preventing air from entering the bag

Steel seal(standard configuration)/

Ribbon code printer(optional)

Print the production date and expiration date, and the date format can be flexibly adjusted.

bag former

Fold the film and back sealing to make different sizes bag via changing the bag former according your requirement size of bag Maximum film width:320mm

Customer praise

Company strength

Certifications

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product

machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is

feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product

machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is

feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Hot Searches