- Product Details

- {{item.text}}

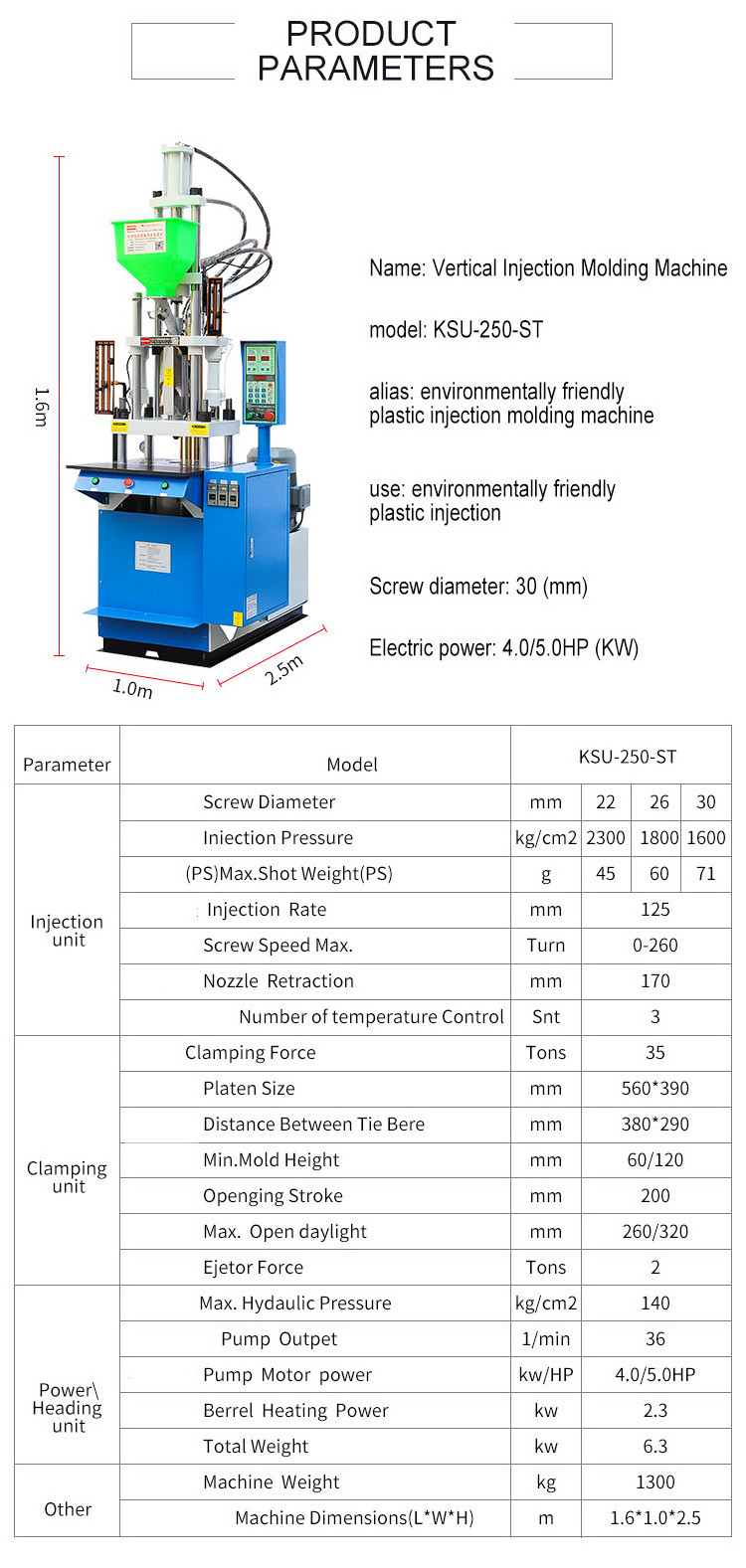

Quick Details

-

Ejector Force(kN):

-

2500 kN

-

Theoretical Shot Volume(cm³):

-

36 cm³

-

Injection Rate (g/s):

-

260 g/s

-

Injection Weight (g):

-

75 g

-

Screw Speed (rpm):

-

0 - 260 rpm

-

Screw diameter (mm):

-

30 mm

-

Weight (KG):

-

1520 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

125 mm

-

Model Number:

-

BORX-250ST

-

Brand Name:

-

BORX

-

Power (kW):

-

6.3 kW

-

Name:

-

Ultra precision vertical injection molding machine

-

Alias:

-

Plastic molding machine

-

Used for:

-

Injection Molding Machine

-

Clamping Force:

-

25Tons

-

Screw stroke:

-

120mm

-

Formwork size:

-

540 * 380mm

-

Product name:

-

Plastic Injection Molding Machine

Quick Details

-

Plasticizing Capacity(g/s):

-

75

-

Mold Height(mm):

-

80 - 140 mm

-

Ejector Stroke(mm):

-

125 mm

-

Ejector Force(kN):

-

2500 kN

-

Theoretical Shot Volume(cm³):

-

36 cm³

-

Injection Rate (g/s):

-

260 g/s

-

Injection Weight (g):

-

75 g

-

Screw Speed (rpm):

-

0 - 260 rpm

-

Screw diameter (mm):

-

30 mm

-

Weight (KG):

-

1520 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

125 mm

-

Model Number:

-

BORX-250ST

-

Brand Name:

-

BORX

-

Power (kW):

-

6.3 kW

-

Name:

-

Ultra precision vertical injection molding machine

-

Alias:

-

Plastic molding machine

-

Used for:

-

Injection Molding Machine

-

Clamping Force:

-

25Tons

-

Screw stroke:

-

120mm

-

Formwork size:

-

540 * 380mm

-

Product name:

-

Plastic Injection Molding Machine

Environmental plastic injection molding machine clamping plastics products electroni data cables manufacturering molding machine 250ST

- Multi-stage temperature control, multi stage injection pressure, shotting speed, back pressure stepless adjustment, suitable for precision plastics parts molding

- BORX-KST-250ST has an automatic cleaning device to facilitate the replament of molds and raw materials.

- The shooting speed, back pressure, and screw speed are steplessly adjusted, suitable for molding various precision engineering plastic parts.

- To ensure the safety of the mold, it has a hydraulic ejector device for the finished product

- It is connected to the automatic embedding and removal equipment, and it will operate automatically when it reached. According to the characteristics and performance requirements of embedded parts, the goal of minimum input and maximum output can be achieved.

- The low pressure protection is accurate, and the whole strokc is smooth and excellent.

Hot Searches