- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

THE K5 PLA Magic

-

Material:

-

Polylactic Acid

-

Product name:

-

PLAK5 Magic

-

Application:

-

FDM/FFF 3D Printer

-

Certificate:

-

RoHS REACH

-

Net Weight:

-

1kg/roll

-

Tolerance:

-

0.01-0.03mm

-

Brand:

-

Kexcelled

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

kexcelled

-

Model Number:

-

THE K5 PLA Magic

-

Material:

-

Polylactic Acid

-

Product name:

-

PLAK5 Magic

-

Application:

-

FDM/FFF 3D Printer

-

Certificate:

-

RoHS REACH

-

Net Weight:

-

1kg/roll

-

Tolerance:

-

0.01-0.03mm

-

Brand:

-

Kexcelled

About Us

Hot Selling

Product Description

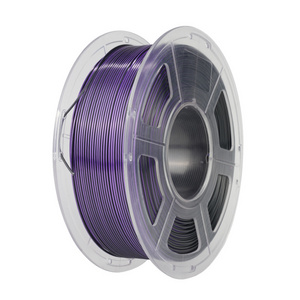

PLA K5 Magic

series was born for the creative aesthetics of 3D printing.The printed products present the visual effects like rocks in nature, making the application scenes of architectural models, scenic spots layout, statues and other artistic decorations more realistic and vivid.

|

Specifications:

|

|

|

|

Filament diameter:

|

Ø1.75mm Ø2.85mm Ø3.0mm

|

|

|

Net Weight:

|

0.5kg 1kg 3kg 5kg

|

|

|

Tolerance:

|

±0.01-0.03mm

|

|

|

Colors:

|

8 colors

|

|

|

Remark:

|

More diameters & weight can be customized.

Own color-masterbatch technology to customize any color.

|

|

|

Parameters:

|

|

|

|

|

||||

|

*

NATURAL ROCK-LIKE VISUAL EFFECT: Based on the PLA K5 series, the texture effect is creatively incorporated into the filament, giving it the visual appearance of natural rock or building material. Both elegant castles and marble sculptures can be presented through it.

|

|

|

|

|

||||

|

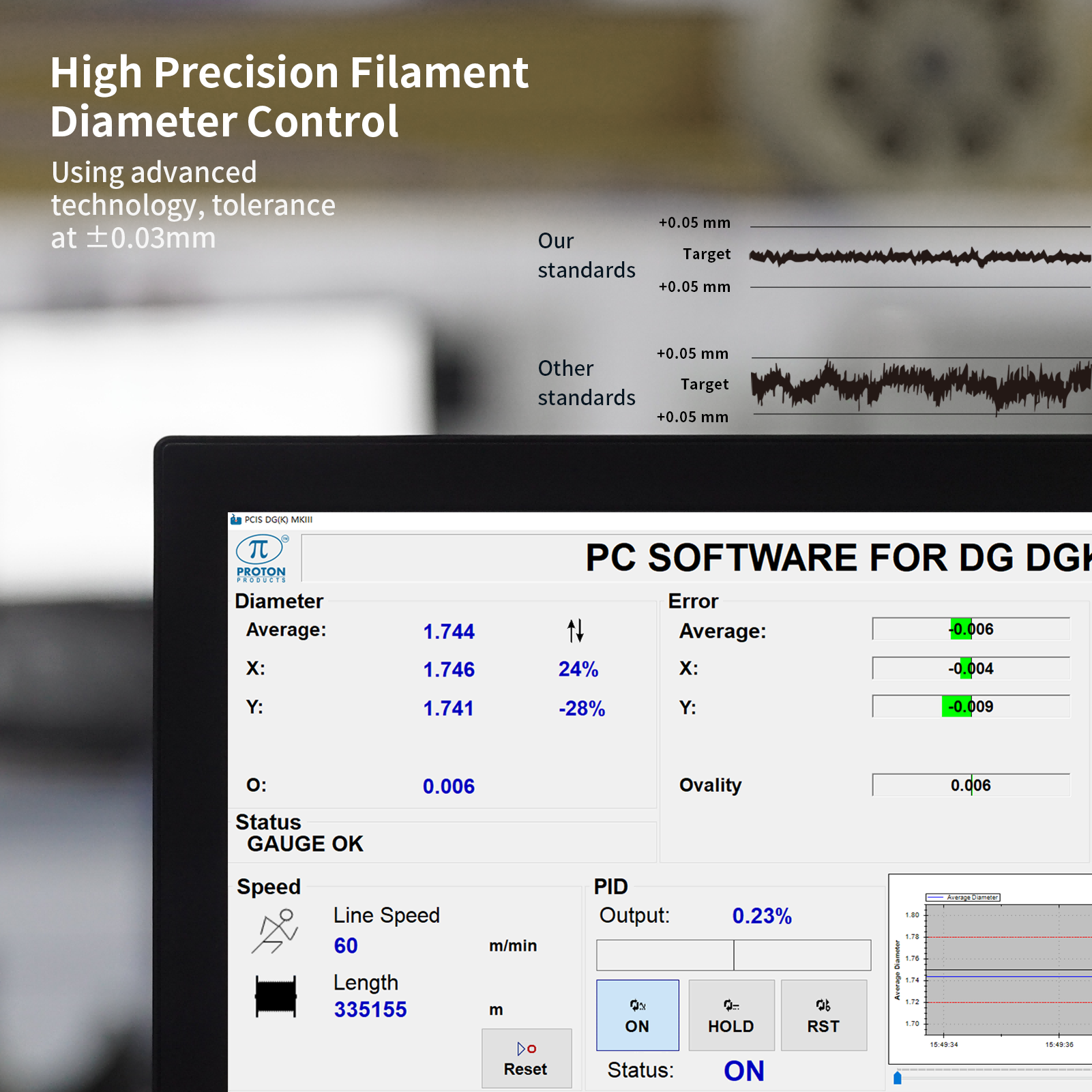

*HIGH CONSISTENCY & DIMENSIONAL ACCURACY: Kexcelled uses an optimized extrusion process and dual defect detection technology to greatly reduce print failures caused by inconsistent filament diameter. The tolerance of PLA K5 Magic filament is strictly controlled to +/-0.03mm.

|

|

|

|

|

||||

|

*

Smooth & stable printing: The introduction of porous micro-nano inorganic materials ensures smooth printing, low shrinkage deformation, low warpage, good adhesion to the platform, easy forming, and good forming accuracy. Can be used to print large parts.

|

|

|

|

|

||||

|

*

STRICT QUALITY CONTROL: Enhanced impact strength and high fluidity enable you to print in wider temperature and speed ranges and keep the surface smooth without warping deformation. Accurate deposition of each layer brings good surface quality. Melt well, feed smoothly and constantly without clogging the nozzle.

|

|

|

|

|

||||

|

Printing Tips:

|

|

|

|

Nozzle temperature:

|

190℃-220℃

|

|

|

Platform temperature:

|

30℃-60℃

|

|

|

Print speed:

|

40-80mm/s

|

|

|

Remark:

|

If you need more product quides and instructions, or you are interested in becoming in our sales agent and business partner, please contact us by email: alibaba@northbridge3d.com.

|

|

Cooperation Partners

Our 3D printing filament perfectly compatible with 99% FDM 3D printer.

Recommend Products

Packaging & After-Sales

General Packaging:

* Each spool packed in a vacuum-sealed package with a desiccant packet.

* Each roll in a small box,

box size:L21XW21XH7.2cm

* 10 small boxes in a carton box

carton size:L45*W38*H23cm

Packaging also can be customized*_*.

After-Sales:

Kexcelled hopes that everyone can experience the fun of 3D printing, so we provide printing technology guidance and customer service. The email will be answered within 24 hours ASAP *_*.

FAQ

What if the surface of the printed model is not smooth and has defects?

1. First, confirm that the filaments are in a dry state. If the unpacking time is too long, it needs to be dried (PLA series

50-55°C, 3h; PETG, WOOD,ABS, etc. 60-65°C, 4h; TPU, 65-70°C, 4h).

2. Appropriately increase or decrease the amount of extrusion.

3. Clean the throat and nozzle.

4. Check whether the extruder gear is worn.

50-55°C, 3h; PETG, WOOD,ABS, etc. 60-65°C, 4h; TPU, 65-70°C, 4h).

2. Appropriately increase or decrease the amount of extrusion.

3. Clean the throat and nozzle.

4. Check whether the extruder gear is worn.

What to do if the printed filament cannot get onto the platform?

1. Adjust the distance between the nozzle and the platform.

2. Reduce the printing speed of the first layer.

3. Adjust the temperature and cooling settings.

4. Platform surface treatment (platform sticker, glue, and material).

5. Increase brim or raft.

2. Reduce the printing speed of the first layer.

3. Adjust the temperature and cooling settings.

4. Platform surface treatment (platform sticker, glue, and material).

5. Increase brim or raft.

What to do if the nozzle is clogged?

1. Reinstall the filament to see if the new one can be extruded normally.

2. Clean the nozzle and use a fine needle smaller than the nozzle diameter to clean or replace with a new nozzle.

3. Check whether the throat cooling fan is operating normally. Abnormal operation of the fan will cause the consumables to flow. The throat swells in advance and causes the plug.

4. Check whether the throat is aging.

2. Clean the nozzle and use a fine needle smaller than the nozzle diameter to clean or replace with a new nozzle.

3. Check whether the throat cooling fan is operating normally. Abnormal operation of the fan will cause the consumables to flow. The throat swells in advance and causes the plug.

4. Check whether the throat is aging.

What to do with stringing?

1. After each use, the filament should be inserted into the round hole on the side of the material tray, and stuck tightly.

2. If the filament has been threaded, relax and pull out until it is not threaded, then re-wound.

2. If the filament has been threaded, relax and pull out until it is not threaded, then re-wound.

Contact information

Asia Factory & Office

NorthBridge New Material Technology Co.,Ltd

W:www.northbridge3d.com

E: alibaba@northbridge3d.com

T: +86-18962115278

F: +86 (0) 512 65801832

A: Xiangcheng Economic Development Zone, Suzhou City, CHINA

EMEA Warehouse & Office

Northbridge Netherlands B.V.

E: alibaba @northbridge3d.com

NorthBridge New Material Technology Co.,Ltd

W:www.northbridge3d.com

E: alibaba@northbridge3d.com

T: +86-18962115278

F: +86 (0) 512 65801832

A: Xiangcheng Economic Development Zone, Suzhou City, CHINA

EMEA Warehouse & Office

Northbridge Netherlands B.V.

E: alibaba @northbridge3d.com

Hot Searches