- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

80#

-

Usage:

-

Polishing

-

Product name:

-

Zirconia Fused Alumina

-

Keyword 1:

-

Zirconia Aluminium

-

keywords:

-

Zirconia alumina

-

Application:

-

polishing

-

True density (g/cm3):

-

4.25

-

Hardness:

-

9.0 Mohs Scale

-

Melting Temperature:

-

1850°C

-

Packaging:

-

25kgs/bag

-

Name:

-

Zirconia Alumina Oxide

-

Sample:

-

Sample Provided

Quick Details

-

Abrasive Grain Sizes:

-

80#

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SICHENG

-

Model Number:

-

80#

-

Usage:

-

Polishing

-

Product name:

-

Zirconia Fused Alumina

-

Keyword 1:

-

Zirconia Aluminium

-

keywords:

-

Zirconia alumina

-

Application:

-

polishing

-

True density (g/cm3):

-

4.25

-

Hardness:

-

9.0 Mohs Scale

-

Melting Temperature:

-

1850°C

-

Packaging:

-

25kgs/bag

-

Name:

-

Zirconia Alumina Oxide

-

Sample:

-

Sample Provided

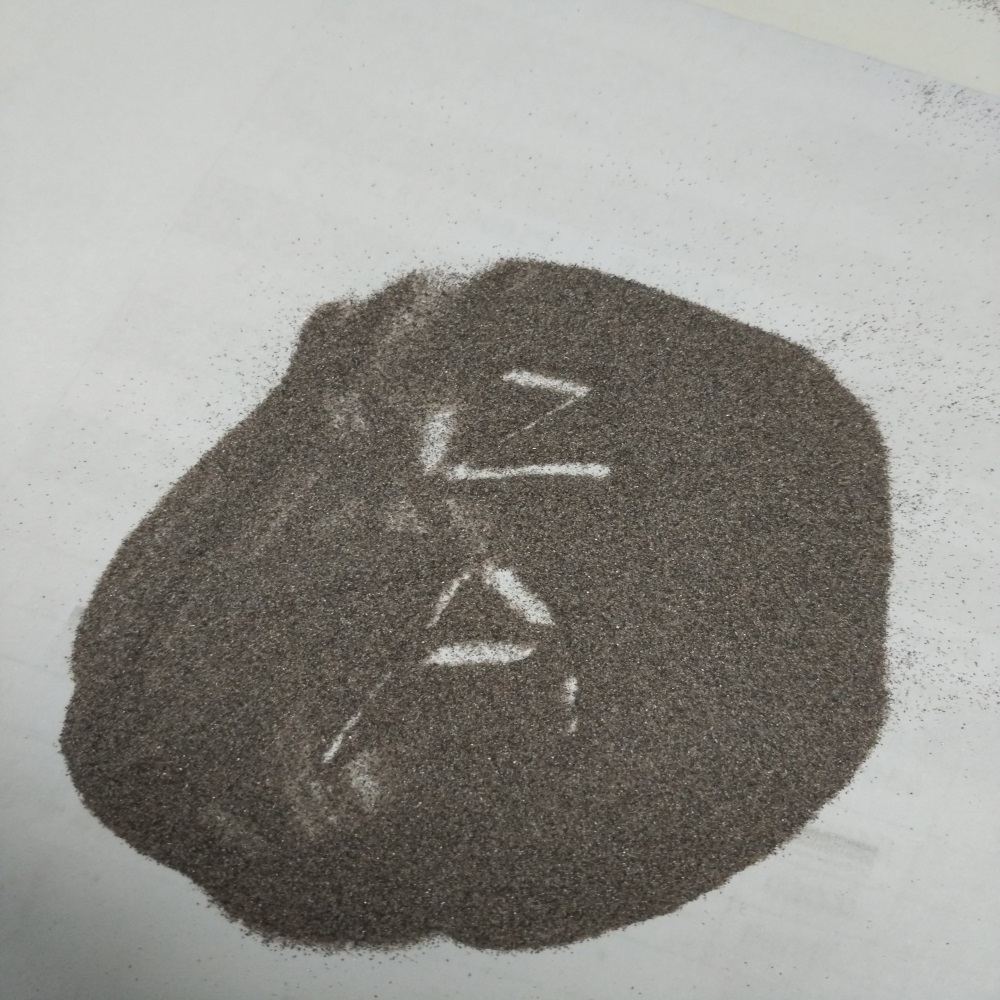

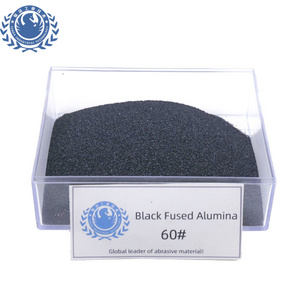

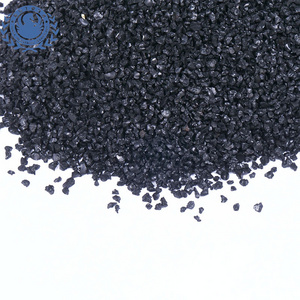

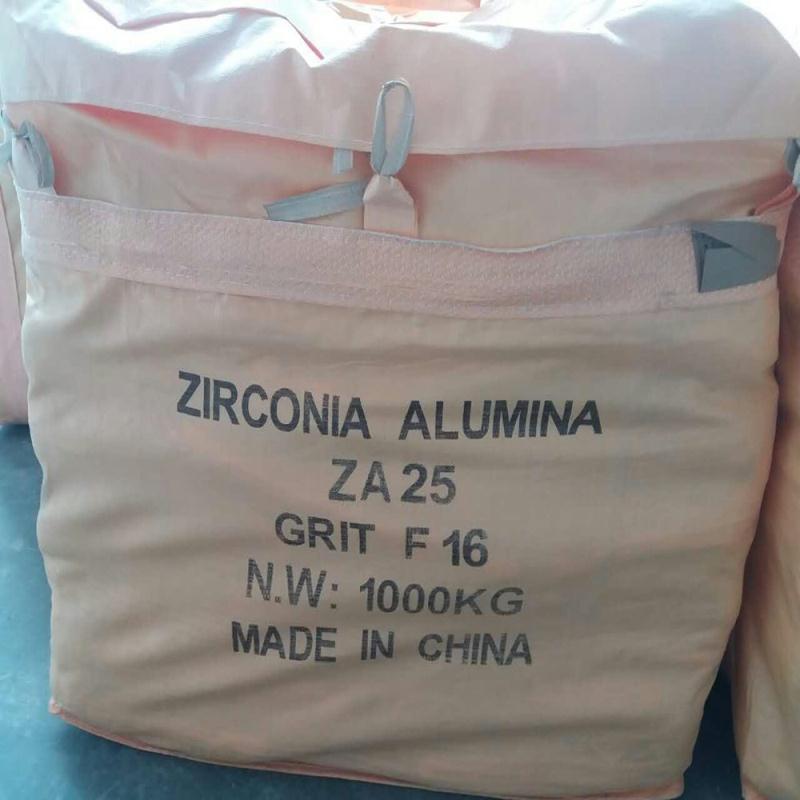

zirconium fused alumina ZA40 sand blasting grit

Brief:

Fused Alumina--Zirconia is produced in a high temperature electrical arc furnace by fusing zirconium quartz sand and alumina. It takes the advantages of high strength, high toughness, high temperature resistance, which can manufacture heavy-duty wheel with high performance, and has achieved very good results in grinding steel, cast iron, heat-resistant alloy steel, titanium alloys, aluminum alloys and austenitic alloy steel. And it is widely used in the production of refractoriness in the steel industry such as continuous casting and rolling, flow channel, and zirconia brick as well.

It is classified into ZA 25 and ZA 40 as the content of ZrO2.

It is characterized by hard and dense structure, high toughness, good thermal stability. It's suitable for manufacturing large grinding wheels for steel conditioning and foundry snagging, coated tools and stone blasting, etc.

Chemical and Physical Characteristics:

Chemical Characteristics

|

Abrasive supply zirconium fused alumina ZA40 micropowder for optical glass |

|||||

|

product |

Al2O3 |

ZrO2 |

TiO2 |

Fe2O3 |

SiO2 |

|

ZA25 |

68%-72% |

24%-30% |

1.0%max |

0.5%max |

0. 8%max |

|

ZA40 |

55%-57% |

35%-44% |

1.0%max |

0.5%max |

0.8%max |

Physical Characteristics

|

Color |

Grey |

|

Shape |

|

|

True Specific Gravity |

4.25g/cm3 |

|

Melting Temperature |

About 1900°C |

|

Magnetic Material |

0.0080% |

|

Bulk Density(g/cm3) |

2.18 |

Applications:

Zirconia Fused Alumina can tolerate melt erosion. As a senior abrasive, it can be used in high performance of heavy-duty wheel manufacturing, and have good grinding effect on steel, cast iron, heat-resistant steel, and various alloys ; In addition, zirconia Fused Alumina is a high-grade refractory materials, and it is an ideal material for manufacturing high performance sliding nozzle and immersion nozzle, can also be used for making zirconium corundum bricks for glass melting furnace.

Packaging & Delivery:

Packaging Details

a. In 25kg plastic woven bags.

c. 40 x 25kg plastic woven bags in one big bag.

d. 40 x 25kg plastic woven bags on pallet.

e. 40 x 25kg paper bags on pallet.

f. According to client's special requirement

Delivery:10-15 working days

Production equipment display: