- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2235*2620*3849mm

-

Motor Power (kW):

-

18.5*4kW*P

-

Model Number:

-

ST-260V

-

Weight (T):

-

30.5

-

Marketing Type:

-

Hot Product 2023

-

Machine name:

-

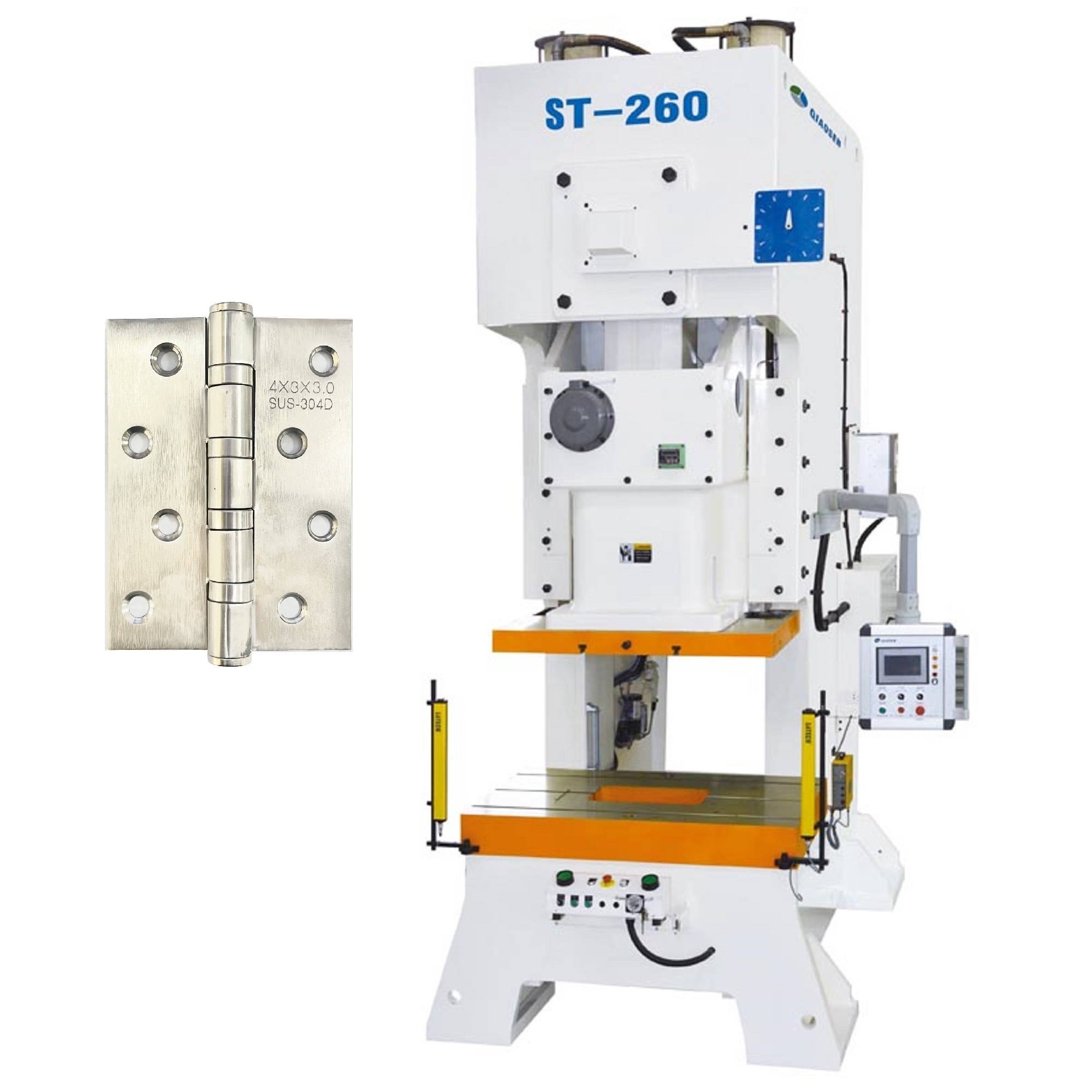

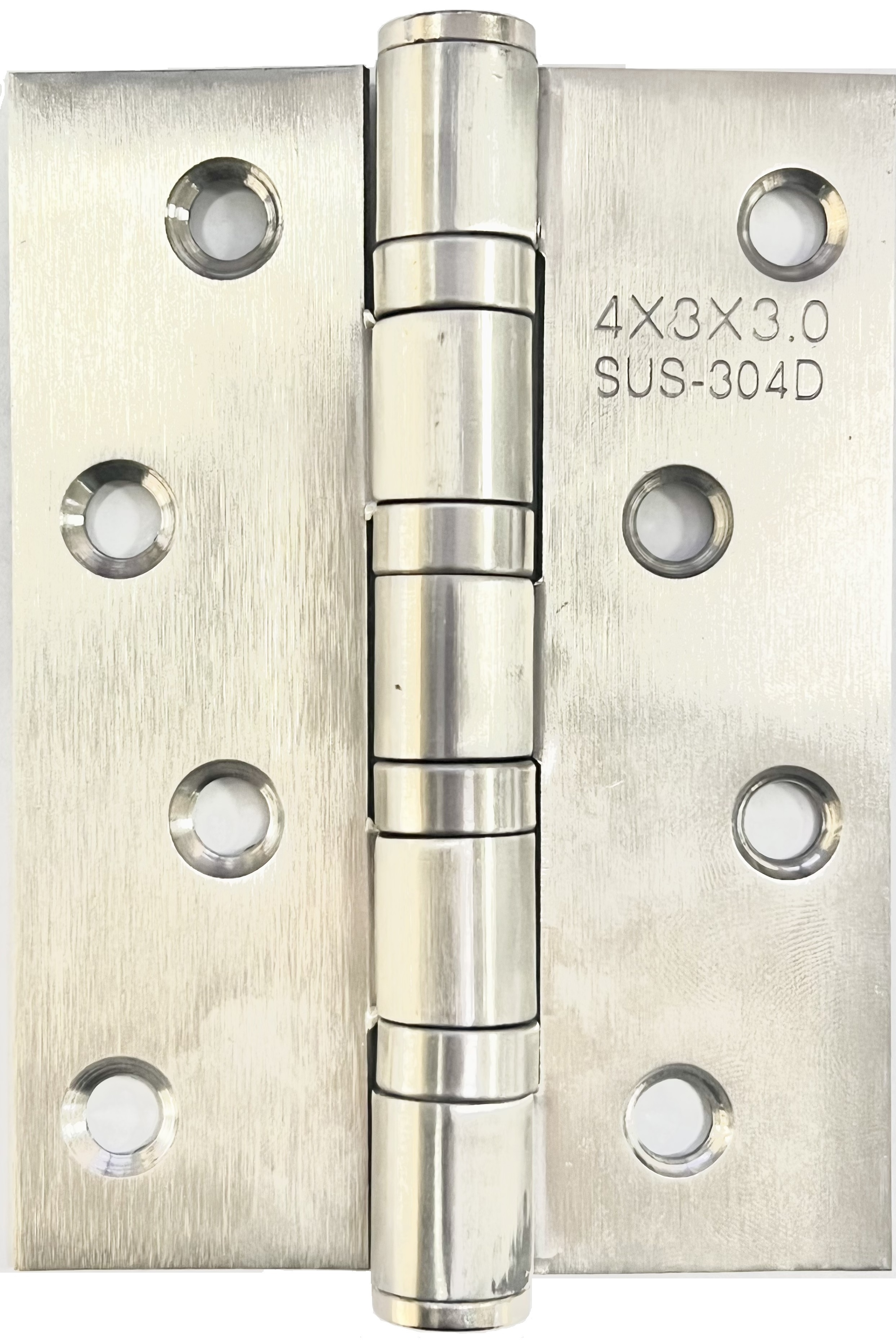

260 tons cabinet hinge press machine

-

Punching capacity:

-

260 tons for cabinet hinge making machine

-

Slider strokes per minute:

-

20-40SPM for hinges manufacturing machine

-

Long slider length:

-

250 mm for stamping machine

-

Punch weight:

-

32 for punch press

-

Maximum mode height:

-

500mm for hinge press machine

-

Material:

-

42CrMo used for Crankshaft, ZQSn10-1 used for Copper sets

-

Color:

-

Customer Request

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Slider guide position stucture::

-

2 corner 6 guide structure

Quick Details

-

Slide Stroke (mm):

-

250mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

QIAOSEN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2235*2620*3849mm

-

Motor Power (kW):

-

18.5*4kW*P

-

Model Number:

-

ST-260V

-

Weight (T):

-

30.5

-

Marketing Type:

-

Hot Product 2023

-

Machine name:

-

260 tons cabinet hinge press machine

-

Punching capacity:

-

260 tons for cabinet hinge making machine

-

Slider strokes per minute:

-

20-40SPM for hinges manufacturing machine

-

Long slider length:

-

250 mm for stamping machine

-

Punch weight:

-

32 for punch press

-

Maximum mode height:

-

500mm for hinge press machine

-

Material:

-

42CrMo used for Crankshaft, ZQSn10-1 used for Copper sets

-

Color:

-

Customer Request

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Slider guide position stucture::

-

2 corner 6 guide structure

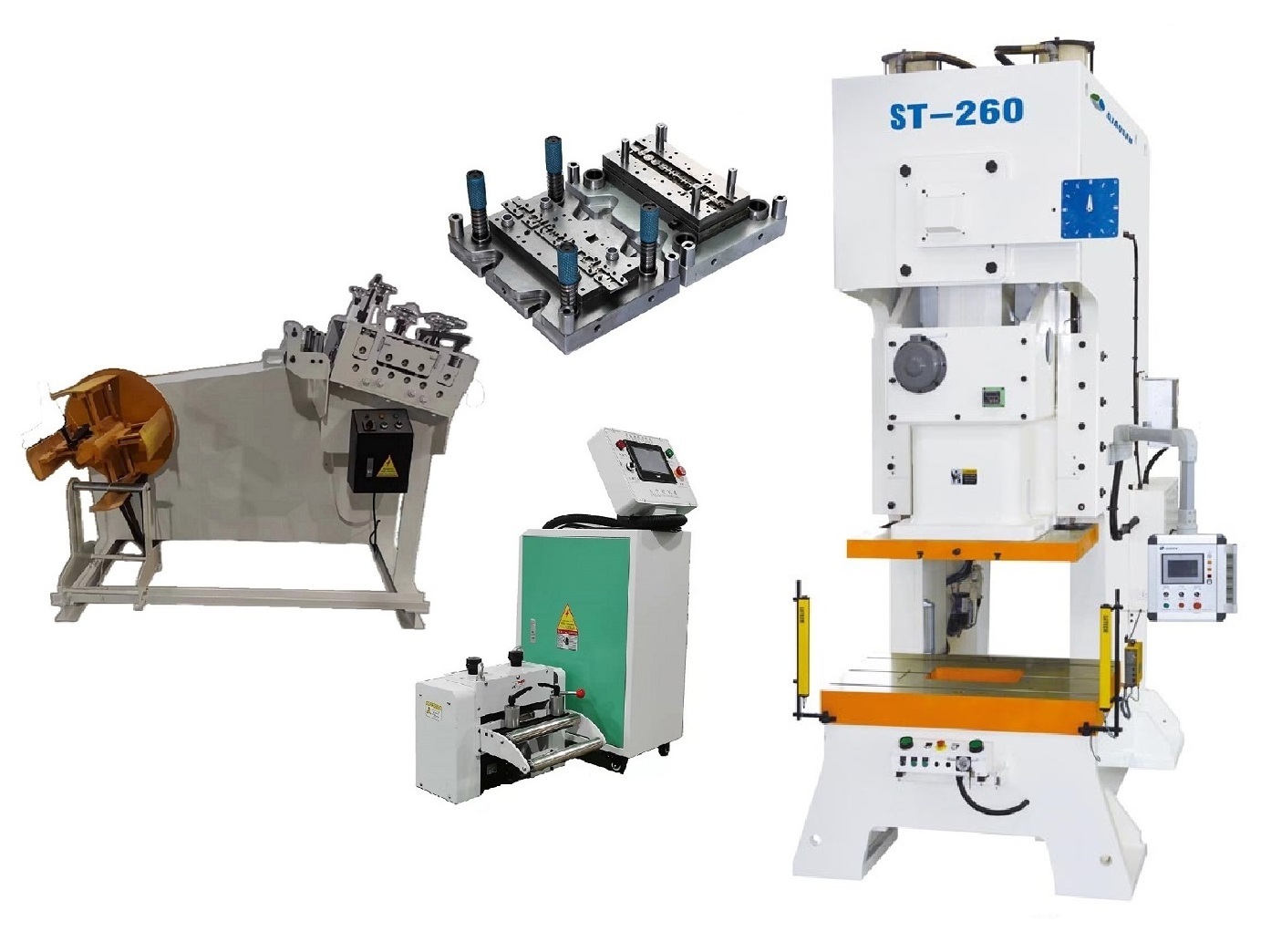

Hinge Making Line Solution

1.Furniture Cabinet Hinge Production Line

The stamping line include :

2 in 1 Straightener and decoiler machine + NC feeder machine + QIAOSEN Press machine+hinge mold

2.Drilling Chamfering Machine

Product Detail

Cabinet Hinge Making Machine , Machinery to produce hinges , Pneumatic press machine

●The high-strength fuselage structure has small deformation and high precision.

●OMPI pneumatic dry clutch brake.

●The slider adopts 2corner and 6sided guides.

●The slider guide adopts"high-frequency quenching" and "rail grinding process",which has small wear, high precision,long precision maintenance time and improve service life.

●Crankshaft is made of high strength alloy 42CrMo, which is 1.3 times stronger than 45 steel.

●The copper sleeve is made of tin

phosphor bronze ZQSn10-1,which is 1.5 times stronger than ordinary BC6 brass.

●Highly sensitive hydraulic overload protection

device protects the press and die service life.

●Optional mat (air cushion).

Product Specifications

|

NO

|

Item

|

Unit

|

ST-260V

|

ST-260H

|

|

|

1

|

Punching capacity

|

ton

|

260

|

|

|

|

2

|

Ability occurrence point

|

mm

|

7

|

3.5

|

|

|

3

|

Slider strokes per minute

|

SPM

|

20-40

|

40-50

|

|

|

4

|

Long slider length

|

mm

|

250

|

150

|

|

|

5

|

Maximum mode height

|

mm

|

500

|

550

|

|

|

6

|

Slider adjustment amount

|

mm

|

120

|

|

|

|

7

|

Up platform area

|

mm

|

1250*700*100

|

|

|

|

8

|

Down platform area

|

mm

|

1500*840*180

|

|

|

|

9

|

Slider center to machine distance

|

mm

|

430

|

|

|

|

10

|

Platform to floor distance

|

mm

|

1030

|

|

|

|

11

|

Shank hole

|

mm

|

ᶲ65

|

|

|

|

12

|

Main motor power

|

kw*p

|

22*4

|

|

|

|

13

|

Air presure

|

kg/cm^2

|

6

|

|

|

|

14

|

Punch accuracy grade

|

|

JIS 1

|

|

|

|

15

|

Punch dimension(L*W*H)

|

mm

|

2780*1850*4470

|

|

|

|

16

|

Punch weight

|

ton

|

32

|

|

|

|

17

|

Die cushion capacity(optional)

|

ton

|

14

|

|

|

|

18

|

Stroke(optional)

|

mm

|

100

|

|

|

|

19

|

Active area(optional)

|

mm

|

810*480

|

|

|

Product Application

This punching press machine is used for stamping sheet metal parts . It can be cooperated with automatic feeding machine and stamping molds to form the automatic production line. It is suitable for blanking, trimming, punching hole, forming, bending, shallow stretching and other cold stamping process. The machine used for different kinds of materials, including metal, copper, aluminum, brass, alloy, steel, iron etc..

Related Products

Hot Searches