- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ABC Machinery

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Actual

-

Motor Power (Kw):

-

132+1.5+3 kw

-

Power (kW):

-

132+1.5+3 kw

-

Weight (KG):

-

4500 KG

-

Marketing Type:

-

Factory Direct Sales

-

Capacity:

-

1.5-2T/h wood pellet plant

-

Raw material:

-

Sawdust

-

Type:

-

complete pellet plant

-

Color:

-

Customer's Request

-

Power Supply:

-

Electric motor for pellet plant

-

Pellet size:

-

4-12mm

-

The final density of pellets:

-

1100kg/m3

-

Model Number:

-

2TPH wood pellet plant

-

Weight:

-

4500 kg

-

Power(W):

-

132+1.5+3 kw

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1500 - 2000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ABC Machinery

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Actual

-

Motor Power (Kw):

-

132+1.5+3 kw

-

Power (kW):

-

132+1.5+3 kw

-

Weight (KG):

-

4500 KG

-

Marketing Type:

-

Factory Direct Sales

-

Capacity:

-

1.5-2T/h wood pellet plant

-

Raw material:

-

Sawdust

-

Type:

-

complete pellet plant

-

Color:

-

Customer's Request

-

Power Supply:

-

Electric motor for pellet plant

-

Pellet size:

-

4-12mm

-

The final density of pellets:

-

1100kg/m3

-

Model Number:

-

2TPH wood pellet plant

-

Weight:

-

4500 kg

-

Power(W):

-

132+1.5+3 kw

2TPH Australia wood pellet plant sawdust pellet machine making complete wood pellet production line

Our first 1.5-2 ton per hour wood pellet plant in Australia since 2012, and this project is Located in Geelong, Vic., Australia. ABC Machinery provides turnkey complete wood pellet production line for the production of sawdust pellets. According to the requests of the Client and of the constructive characteristics, our plants have different construction characteristics and production capacity sawdust pellet machine. We have been engaged in the biomass pellets industry for over 20 years, and the export of pellet equipment to all parts of the world.

Whole view complete wood pellet production line

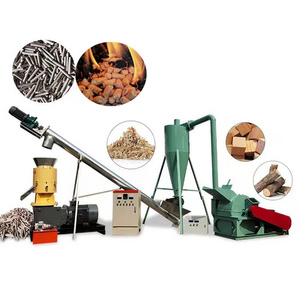

The capacity of wood pellet plant is from 1.5 to 2 tons per hour. It is taking the mixture of softwood and hardwood sawdust as feedstock, The proportion of softwood against hardwood goes 9:1, with the moisture content of feedstock 12% or so.

The complete wood pellet production line mainly covers pulverizing, drying, mixing, pelleting, cooling and packaging which it is including jumbo bag and small bag.T he smaller bagger used for 15KG per bag and the bulk bagger for 1 ton can meet the demands for different weighs of pellets in the market.

Click Now for Catalogs & Factory Price !

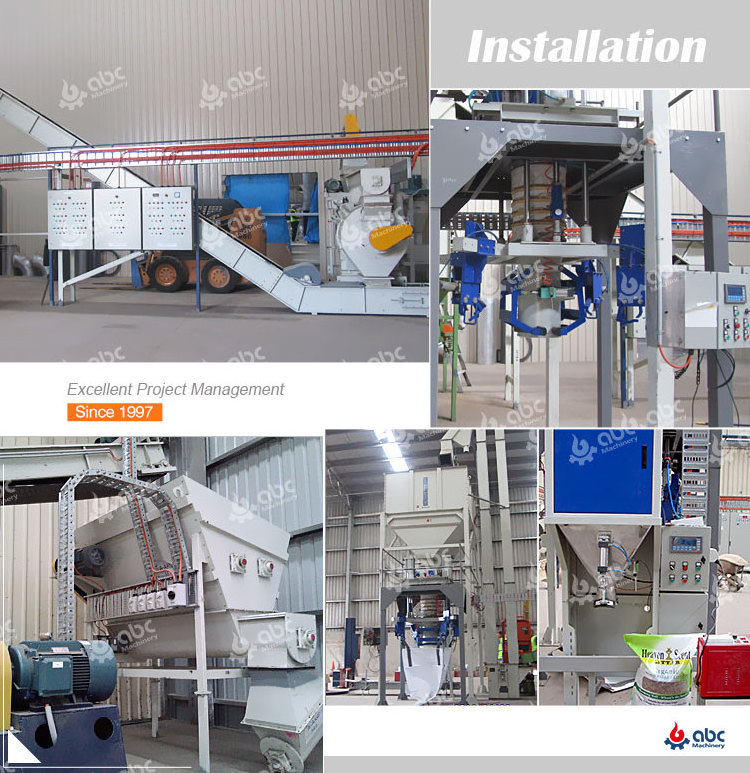

Install photo of complete wood pellet production line

Due to the thriving of biomass pellets industry, the demand for sawdust pellet machine is increasing. ABC machinery is committed to providing a complete set of solutions for pellet making for more than 20 years . The complete pellet plant can be used to produce sawdust, wood chips, branches, straw, hay and other biomass raw material pellets. The whole complete wood pellet plant can be controlled by PLC automatic control system.

Click Now for Catalogs & Factory Price !

What can be used for wood pellet production?

The wood pellet plant can make forestry waste, sawdust, branches, bark; farmland waste, straw, fruit shell, etc. into biomass pellets for burning or other use like horse beding, cat litter.

Complete wood pellet plant

Click Now for Catalogs & Factory Price !

Details of ring die of sawdust pellet machine

The pellet mill die is one of the important parts of sawdust pellet machine. If there is a problem with the pellet mill die, then the whole wood pellet plant will not work. The “pellet mill die” in a ring die pellet mill is the first and the most important part you shall exam while buying a pellet mill or pellet plant.

Click Now for Catalogs & Factory Price !

Turnkey wood pellet plant projects

ABC Machinery supply the sawdust pellet machine with the best performance price ratio along with holistic import solutions and customized wood pellet plant plan.

Click Now for Catalogs & Factory Price !

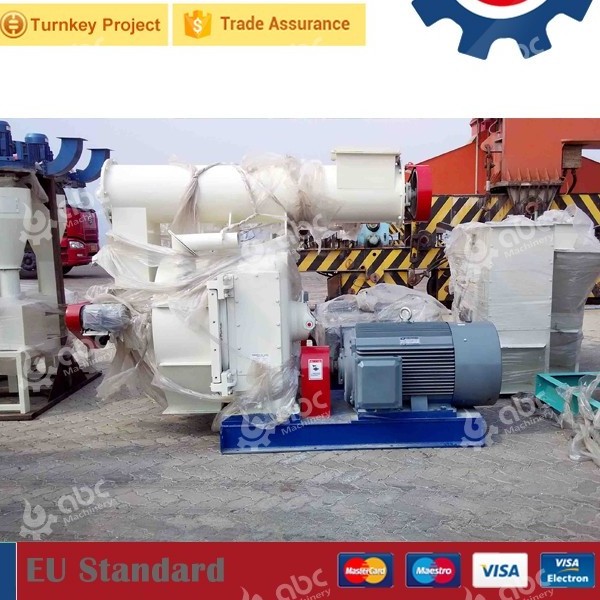

Shipment of wood pellet mill

Why choose ABC Machinery

Welcome to contact to build your own wood pellet production line