1) Adopt high-precision gear drive advanced flexible coupling, for high productive efficiency.

2) Main driving adopt imported FAG bearing, and Siemens motor.

3) Frequency converter control feeder flow, full stainless steel cover and chute.

4) Full stainless steel lengthened conditioner; both paddle and shaft are made of stainless steel.

5) With CE certificate.

6) Available for testing before delivery.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

customized

-

Power:

-

380V, 50HZ

-

Name:

-

wood pellets making machine with heating sealer and sewing machine

-

Product name:

-

feed pellets automatic making machine price

-

Usage:

-

soybean sugar rice making machine

-

Capacity:

-

5-50kg/bag

-

sealer:

-

heating, sewing, or both

-

Advantages:

-

accept special requirements, stainless steel contact, double needles

-

Color:

-

Custimized

-

Bale weight:

-

50-80kg/Blaer

-

Raw material:

-

Wood sawdust

-

Warranty:

-

5 years

-

Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory, Home Use, Retail, Food & Beverage Shops

-

Showroom Location:

-

None

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

Ordinary Product

-

Warranty of core components:

-

5 years

-

Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Gear

-

Application:

-

Food, Chemical, Machinery & Hardware

-

Packaging Type:

-

Bags, Film, Belt

-

Driven Type:

-

Electric

-

Key Selling Points:

-

Long Service Life

-

Type:

-

Other

Quick Details

-

Brand Name:

-

LEABON

-

Dimension(L*W*H):

-

2650*1100*2750MM

-

Weight:

-

1000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

customized

-

Power:

-

380V, 50HZ

-

Name:

-

wood pellets making machine with heating sealer and sewing machine

-

Product name:

-

feed pellets automatic making machine price

-

Usage:

-

soybean sugar rice making machine

-

Capacity:

-

5-50kg/bag

-

sealer:

-

heating, sewing, or both

-

Advantages:

-

accept special requirements, stainless steel contact, double needles

-

Color:

-

Custimized

-

Bale weight:

-

50-80kg/Blaer

-

Raw material:

-

Wood sawdust

-

Warranty:

-

5 years

-

Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory, Home Use, Retail, Food & Beverage Shops

-

Showroom Location:

-

None

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

Ordinary Product

-

Warranty of core components:

-

5 years

-

Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Gear

-

Application:

-

Food, Chemical, Machinery & Hardware

-

Packaging Type:

-

Bags, Film, Belt

-

Driven Type:

-

Electric

-

Key Selling Points:

-

Long Service Life

-

Type:

-

Other

Product Description

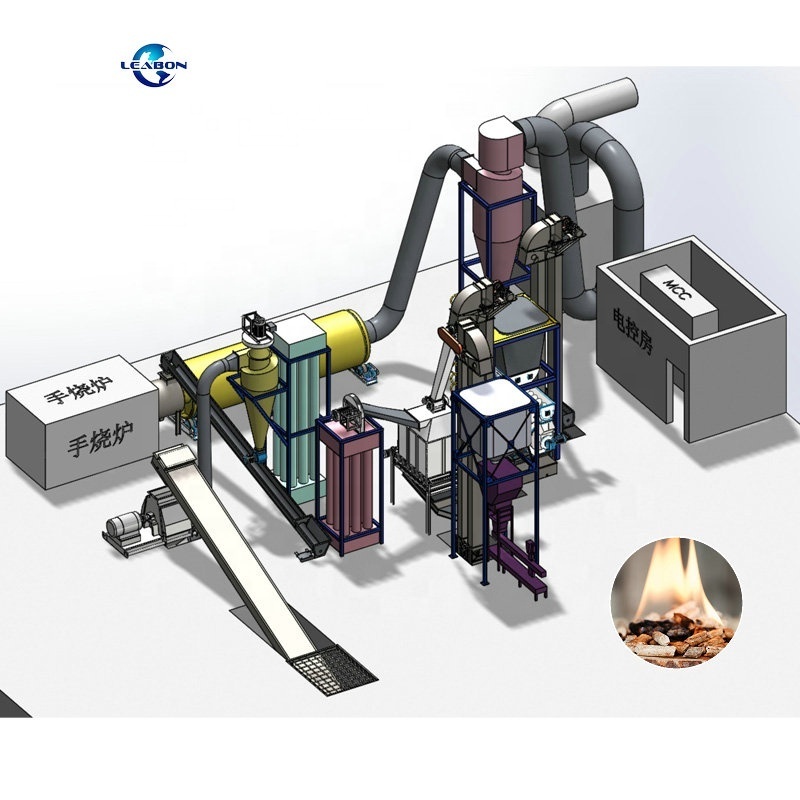

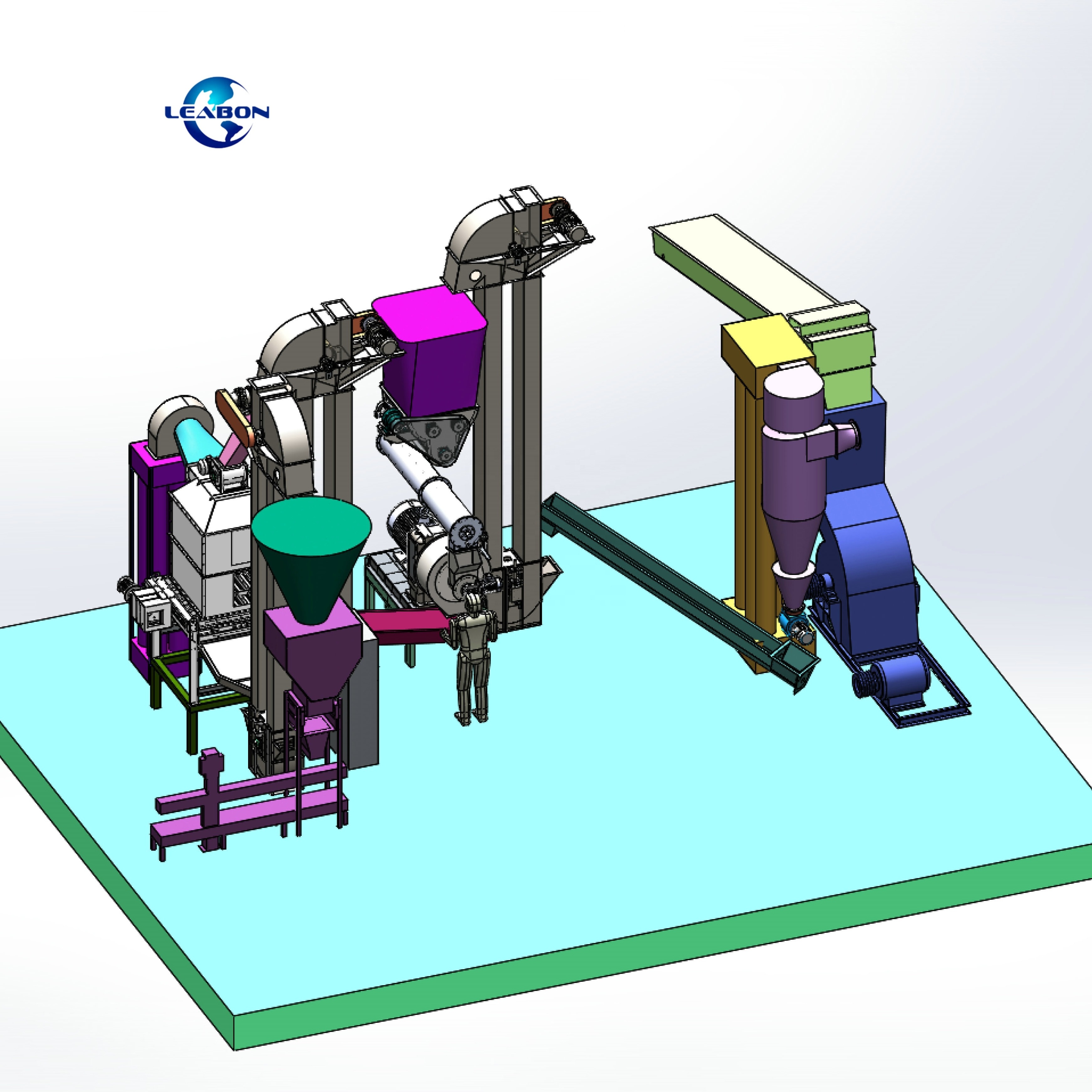

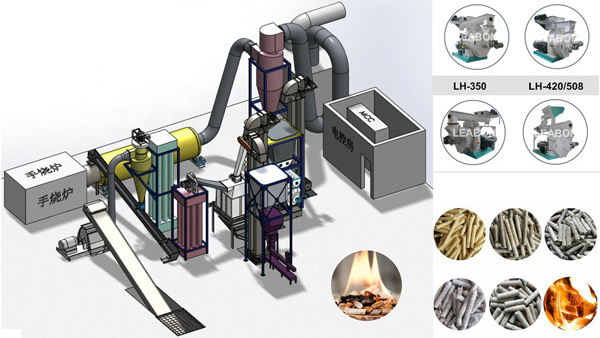

Ring Die Sawdust Wood Pellet Plant/ Wood Pellet Production Line/Complete Wood Pellet Line

LEABON ring die wood pellet production line are he modification machine from feed pellet mill , after doing some research based on the characteristics of biomass fuel pelletizing, they are mainly used to compress the crushed biomass materials like sawdust ,grass, straw and other flammable materials into pellets.

LEABON ring die wood pellet production line is adopted with frequency control motor feeding, overload protectiion device, outside discharging mechanism and automatic lubrication system .

Features:

Main data

|

Model

|

Main Power

(kw)

|

Capacity(t/h)

|

Feeding Power(KW)

|

Conditioner Power(kw)

|

Die Diameter

(mm)

|

Pellet size(mm)

|

|

LH-320

|

37

|

0.2-0.3

|

1.5

|

2.2

|

320

|

6,8,10,12

|

|

LH-350

|

55

|

0.5-0.7

|

1.5

|

3

|

350

|

6,8,10,12

|

|

LH-420

|

90

|

0.8-1.2

|

2.2

|

5.5

|

420

|

6,8,10,12

|

|

LH-480

|

90

|

1.0-1.3

|

2.2

|

5.5

|

480

|

6,8,10,12

|

|

LH-508

|

132

|

1.7-2.2

|

2.2

|

5.5

|

508

|

6,8,10,12

|

|

LH-558

|

160

|

2.0-2.5

|

2.2

|

5.5

|

572

|

6,8,10,12

|

|

LH-678

|

185

|

2.5-3.5

|

3

|

11

|

678

|

6,8,10,12

|

|

LH-768

|

250

|

4.0-5.5

|

4

|

18.5

|

768

|

6,8,10,12

|

Detailed Images

Ring die wood pellet mill is widely used in compacting of wood, straw, other biomass sources into pellet. Capacity ranges from 1T

to 10T per hour. Our LH series pellet mill adopt SKF bearings from Sweden and NSK bearings from Japan, Siemens motors, high

quality components make the pellet mill more efficient and durable.

to 10T per hour. Our LH series pellet mill adopt SKF bearings from Sweden and NSK bearings from Japan, Siemens motors, high

quality components make the pellet mill more efficient and durable.

Raw materials:

The Raw material can be crops of corn stalk, wheat straw, rice straw, peanut shell, corn cob, cotton, soybean pole, chaff,

weed,branches, leaves, sawdust, tree bark and other solid wastes.

weed,branches, leaves, sawdust, tree bark and other solid wastes.

final pellets:

Certifications

Packing & Delivery

Complete Wood Pellet Production Line:

Contact Lynn

If you want to know more about our piston briquette machine, please feel free to contact Lynn:

Hot Searches