- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

Customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

600

-

Applicable Industries:

-

Coating field

-

Product Name:

-

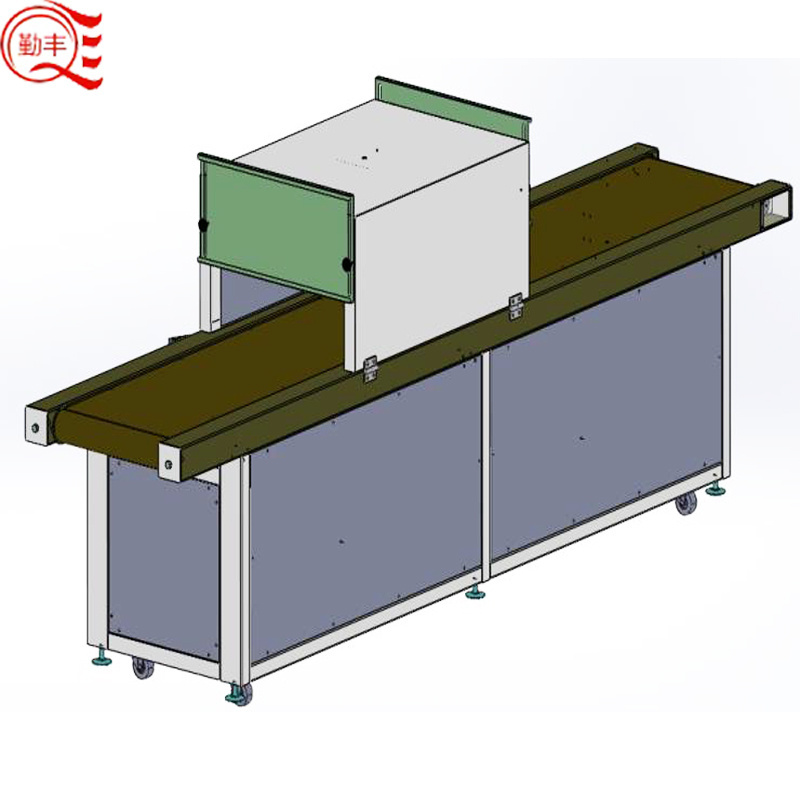

Industrial Drying tunnel furnace

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

TRY:

-

AUTO Constant temperature heating

-

Max temperature:

-

<500c

-

performance:

-

hot air oven Warranty life up to 10 years,Speed can be adjusted

-

type:

-

Explosion-proof type,performance is high

-

Heating source:

-

Electricity for IR tube

-

Heating:

-

Electric Heating Drying Oven

-

Drying Oven Application:

-

Industrial Dryer Oven

Quick Details

-

Type:

-

Spray Drying Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Xinqinfeng

-

Voltage:

-

380V 50HZ

-

Power:

-

Customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

600

-

Applicable Industries:

-

Coating field

-

Product Name:

-

Industrial Drying tunnel furnace

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

TRY:

-

AUTO Constant temperature heating

-

Max temperature:

-

<500c

-

performance:

-

hot air oven Warranty life up to 10 years,Speed can be adjusted

-

type:

-

Explosion-proof type,performance is high

-

Heating source:

-

Electricity for IR tube

-

Heating:

-

Electric Heating Drying Oven

-

Drying Oven Application:

-

Industrial Dryer Oven

China OEM Customized electric heating curing oven furnace

Production Features:

- 1.The material of effective drying liner is 304 stainless steel,with high cleanliness feature.

- 2.With opening type design,very portable and convenient to test and maintenance.

- 3.The adjustable foot cup and the universal wheel is equipped easy to transport and insall.

- 4.The conveyor speed can be adjustable according to your requirements

- 5.The touch screen with PLC control can be provided

-

6.Inside and outside of produce is heated evenly, The quality is stable, not deformed,not discolored.

-

7.It can be used with the automatic spraying line and production line,which can effectively control the labor, reducing the handing,reducing the bad product,Saving time.

-

8.The temperature can be controller in sections to adapt the change of product, The reasonable temperature curve make the quality more stable,anti-explosion and environmental protection.

-

9.The shell surface temperature is almost 40℃,can be touch by hand,which can reduce the energy consumption. The working environment will be more comfortable.

Application:

The Tunnel Furnace has the teflon tunnel furnace, PVC tunnel furnace,steel wire melt furnace etc, which can be widely used to the electronics, plastic,leather,wooden,hardware,glass etc fields.

Tunnel Furnace Equipment Parameter List

|

No. |

Item |

Specificatio n |

|

A |

The conveyor line of Drying oven |

Size :L 4500 mm × W 800 mm × H 780 mm ( Qty:1pcs ) |

|

B |

Drying furnace cover |

The inner size is L 3000 mm × W 600 mm × H 350 mm ( effective height) |

|

1 |

The outside size of furnace |

L3000 mm × W 600 mm × H 500 mm (including the suction section on both ends) |

|

2 |

The outside plate material |

The outside plate is made of 1.2t folding welding cold plate. The inner plate of furnace cover is made of 1.0t galvanized sheets. 50mm thick insulation cotton is filled up. |

|

3 |

The electrical heated tube |

It uses quartz infrared heating tube. The height between the product and light is 200mm. The total power is12KW. |

|

4 |

The wind motor |

Each part has the hot air circulating system. The power is 180W. 4 inch special fan blade make the heat flowing evenly in the furnace come true. |

|

5 |

Temperature |

The design temperature is adjusted from room temperature to 80 ℃ . the temperature differential is plus and minus 5 ℃ |