HENGKO

manufactures filter in a broad range of materials, sizes, and fittings so they can be easily specified with the

characteristics and configurations customers require. We can incorporate custom features or create completely original filter designs for specialized needs. Our filter also come a variety of different alloys, each with their own special benefits and application purposes. They are a popular choice for many industrial filtration applications due to their heat, corrosion, and physical wear resistance.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HENGKO

-

Filter Rating:

-

99%

-

Thickness:

-

OEM

-

Length:

-

Requirement

-

Width:

-

Custom

-

Products name:

-

5 microns multilayer wire mesh sintered stainless steel water filter

-

Technique:

-

Wire Mesh/powder sintering

-

Pore size:

-

0.2-120um

-

Porosity:

-

35%-45%

-

Certificate:

-

ISO9001

-

Filter media:

-

Porous Metal

-

Application:

-

filtration system

-

Feature:

-

high temperature, high pressure, dedicate appearance

Quick Details

-

Weight (KG):

-

0.2

-

Core Components:

-

ss filter

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HENGKO

-

Filter Rating:

-

99%

-

Thickness:

-

OEM

-

Length:

-

Requirement

-

Width:

-

Custom

-

Products name:

-

5 microns multilayer wire mesh sintered stainless steel water filter

-

Technique:

-

Wire Mesh/powder sintering

-

Pore size:

-

0.2-120um

-

Porosity:

-

35%-45%

-

Certificate:

-

ISO9001

-

Filter media:

-

Porous Metal

-

Application:

-

filtration system

-

Feature:

-

high temperature, high pressure, dedicate appearance

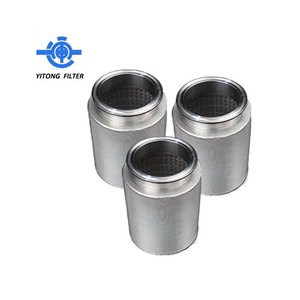

HENGKO Factory 5~300 Microns Multilayer Wire Mesh Sintered Stainless Steel Water Filter

Detailed Images

|

Material

|

stainless steel , SUS316L, 304, Nickel , titanium , bronze, brass, copper

|

|

Specifications

|

filter, filter cartridge, filter plate, filter tube, filter disc, cone filter, filter cap, filter cup , filter disk

|

|

Types

|

Sintered powder, sintering mesh, sinter nets

|

In applications with sustained high temperatures and corrosive environments any pressure-driven filtration process with high operating expenses can be improved with sintered metal filtration technology. Suitable applications can be found in refineries, chemical and petrochemical processes, semiconductor processes and in pharmaceutical production.

HENGKO Sintered Disc Filters

Porous Sintered Metal Filters consist of highly uniform, interconnected networks of pores with tortuous paths that trap solid particles in gas or liquid flow streams. Excellent depth filters with superior mechanical strength. Stainless Steel Type 316L withstands temperatures up to 750°F (399°C) in oxidizing and 900°F (482°C) in reducing environments. These steam autoclavable filters can be cleaned by other methods, such as ultrasonic baths or reverse flow flushing. If your application requires even greater resistance to corrosion, temperature, wear, and vibration, other nickel-based alloys are available.

WHY POROUS METAL?

Filtration systems using sintered metal media for gaseous, solid and liquid separation have proven to be an effective and efficient alternative to other separation methods that can be vulnerable to pressure peaks, high temperatures and/or corrosive environments. Sintered metal is highly efficient in removing particulates, delivers a reliable performance, is easy to clean and has a long life in comparison with leaf filters, filter bags and plate and frame filters.

Feature:

High technology special process molding

The material used to produce these filters is 316L stainless steel. They are made by uniaxial compaction of powder in a rigid tool with the negative shape of the part, and then sintered. The pore size is adjusted by changing the compaction pressure and/or the particle size of the powder.

Powder metallurgy technology is able to create other shapes, such as blind cylinders and other special geometries. In these cases it is necessary to build a specific tool according to the required design.

Related Products

Shiping & Payment

Certificate

Certificatate by CE, ISO9001, FCC, ROSH etc. Patents 30+

Company Introduction

HENGKO

has extensive experience in providing innovative filtration and separations solutions to the global food and beverage industry. We committed to partnering with our customers to improve process control, increase production efficiency and reduce

costs, whilst protecting final product quality.

Our dedicated test, development and laboratory services underpin our design and

development activity, from filtration media and material characterisation, product verification testing to customer scale-up trials and in-service performance evaluation.

Our advantange:

1. Excellent design 2. Senior service team 3. Export certification 4. High stability and precision

*

20 YEARS OEM EXPERIENCE,

Focus on sintered stainless steel filter industry, s

upport customized service

*

Our company has experienced product development teams, high quality services and solutions

*

Accurate, stable, professional and high challenge products.

*

Our products are delivered to customers after passing the quality inspection

*

Provide 100% high-quality pre-sales and after-sales service until the customer is satisfied

Exhibition

FAQ

Q1. Are you manufacturer or trading company?

--We are direct manufacturer specializing in porous sintered metal filters.

Q2. What’s the delivery time ?

--Normal model 7-10 work days because we have ability to do the stock. For big order, it takes about 10-15 work days.

Q3. What is your MOQ?

-- Usually, it is 100PCS, but if we have other orders together, can help you with small QTY also.

Q4. What payment ways available?

-- Western Union, Paypal , T/T , Credit Card , online bank transfer, RMB , etc.

Q5. If sample first possible?

-- Sure, usually we have certain QTY of free samples, if not, we'll charge accordingly.

Q6. We have design, can you produce?

--Yes, welcome!

Q7. Which market do you already sell?

--We already ship to Europe, Middle East, Asia, South America , Afria, North America etc.

Contac Us

Hot Searches