With oil capacity and temperature resistance, it is suitable for various types of metal fasteners with slight oil film surface. The recommended fastener size is M6-M25.

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

C50H94O24

-

Place of Origin:

-

Zhengjiang,China

-

Brand Name:

-

Magic Drip

-

Model Number:

-

AX5

-

Type:

-

Retaining Compound

-

Product name:

-

Threadlocker

-

Color:

-

Blue

-

Package:

-

25pcs/box

-

Feature:

-

Low strength/easy use

-

Shelf life:

-

2 years

-

MOQ:

-

1pc

-

Component:

-

1 Component

-

Volume:

-

500ml

-

Curing time:

-

10 mins

-

Viscosity:

-

900-1500Mpa.s

Quick Details

-

CAS No.:

-

Mixture

-

Other Names:

-

Retaining Compound Glue

-

MF:

-

C50H94O24

-

EINECS No.:

-

C50H94O24

-

Place of Origin:

-

Zhengjiang,China

-

Brand Name:

-

Magic Drip

-

Model Number:

-

AX5

-

Type:

-

Retaining Compound

-

Product name:

-

Threadlocker

-

Color:

-

Blue

-

Package:

-

25pcs/box

-

Feature:

-

Low strength/easy use

-

Shelf life:

-

2 years

-

MOQ:

-

1pc

-

Component:

-

1 Component

-

Volume:

-

500ml

-

Curing time:

-

10 mins

-

Viscosity:

-

900-1500Mpa.s

Application

|

|

Magic Drip AX1

|

Magic Drip AX3

|

Magic Drip AX5

|

Magic Drip AX6

|

Magic Drip AX7

|

Magic Drip AX8

|

Magic Drip AX9

|

|

Strength

|

Low Strength Easy Disassembly Thixotropy

|

High Strength High Temperature Resistance

|

Medium And High Strength

Removable |

High Strength

Difficult To Disassemble |

High Strength

Difficult To Disassemble |

High Strength

Permanent Locking |

Medium And High Strength

Low Viscosity Penetration Grade |

|

Color

|

Purple

|

Orange

|

Blue

|

Blue

|

Red

|

Red

|

Green

|

|

Maximum Disassembly Torque (N.m)

|

14

|

25

|

24

|

39

|

23-40

|

32

|

29

|

|

Fastener Size

|

≤M6

|

≥M25

|

M6-M25

|

≤M25

|

≤M25

|

≥M25

|

M2-M12

|

|

Viscosity (MPa. S)

|

900-1500

|

4000-5000

|

1300-3000

|

400-600

|

400-600

|

6000-8000

|

20-50

|

|

Temperature Resistance

|

150℃

|

232℃

|

180℃

|

180℃

|

150℃

|

150℃

|

150℃

|

|

Initial Fixation/ Full Fixation Time

|

10 mis / 24 hours |

50 mis / 24 hours

|

10 mis / 24 hours

|

10 mis / 24 hours

|

10 mis / 24 hours

|

30 mis / 24 hours

|

20 mis / 24 hours

|

|

Application

|

Removable, locking thread ≤ M6, applicable to all kinds of metal fasteners that need to be removed frequently

|

High strength, high temperature resistance, suitable for permanent locking and sealing of metal thread fasteners, suitable for

permanent locking ≥ M25 thread fasteners |

With oil capacity and temperature resistance, it is suitable for various types of metal fasteners with slight oil film surface.

The recommended fastener size is M6-M25 |

High oil resistance and temperature resistance, and can withstand a small amount of industrial oil stain. Suitable for inert metal

surfaces |

High strength, fluorescent, fast curing, suitable for permanent locking and sealing metal fasteners

|

Ultra high strength, difficult to disassemble, suitable for locking and sealing of large bolt fasteners with coarse teeth more

than M25 |

Low viscosity, penetration grade, used to lock pre installed fasteners. It is recommended to use threaded fasteners with size ≤

M25 |

|

Brand

|

Magic Drip

|

|

Model

|

AX5

|

|

Color

|

Blue

|

|

Strength Grade

|

Medium and high strength

|

|

Viscosity

|

1300-3000 mpas

|

|

Loosening Torque Nm

|

>24

|

|

Thread Size

|

M25

|

|

Temperature Range

|

-55℃-180℃

|

|

Complete Curing Time

|

24h

|

Step.01

Open the bottle cap and pull out the glue nozzle

Step.02

Dispensing on parts to be fixed

Step.02

Assemble the parts quickly after dispensing

HOW TO USE?

2. Apply anaerobic glue: apply enough anaerobic glue to fill the gap.

3. Assembly: it shall be positioned as soon as possible, and it is not allowed to move after positioning.

4. Curing: generally, the anaerobic adhesive can reach the service strength in 1 hour and the curing strength in 24 hours.

Attention

2.

The anaerobic adhesive shall be stored in a cool and dry place and shall not be exposed to the sun. If it is refrigerated at 8 ℃- 23 ℃, the adhesive shall be used after reaching room temperature.

3.

Suitable for locking and sealing between metals. It is not suitable for porous materials such as plastic, wood and paper. For active metals such as steel, copper and their alloys, the surface curing is fast and the strength is high.For stainless steel, zinc, cadmium and other metal surfaces, the curing is slow and the strength is low.

4.

Curing conditions, airtight use on two kinds of metal surfaces without air.

5.

If the adhesive force is too large during removal, the parts can be heated to 200-300 ℃ and removed while hot; It can also be disassembled after running in anaerobic glue remover or acetone for a long time.

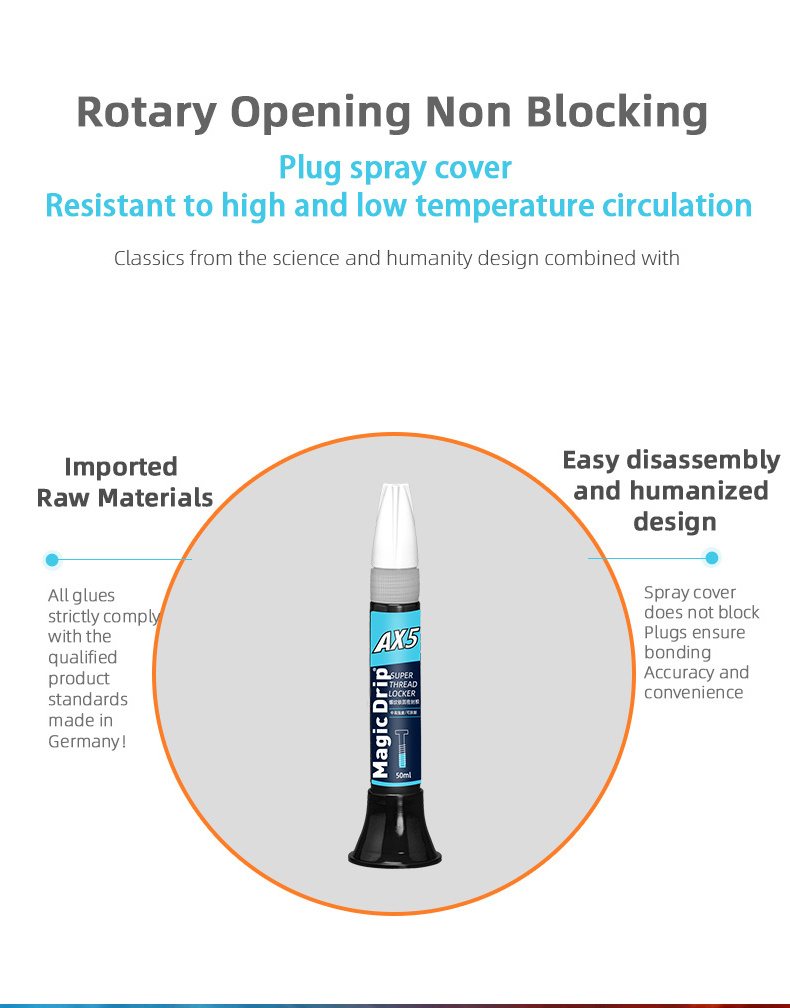

Assured quality

The glue strictly complies with the environmental protection and safety product standards made in Switzerland!

Tips

Several points to pay attention to when purchasing the package with degumming agent:

1.

The degumming agent is corrosive to some plastic products (such as ABS, acrylic, etc.), leather, rubber cotton cloth, fiber cloth, inferior paint surface, inner screen of electronic products, etc.

2.

For materials that have been bonded together, the release glue is difficult to penetrate into the glue in contact, so it can't be dissolved.

3.

Degumming agent is not suitable for AB glue, sewing agent, glass glue, thread glue, hot melt agent, silica gel, etc.

4.

Before degumming, it is recommended to try it in a small area first, and then use it in a large area if there is no abnormality.

COMMOM PROBLEMS

Q:

What's the trick to bonding tightly together?

A:

Try to ensure that the bonding surface is flat and clean, so as to achieve the best use effect. (clean up the bonding surface before bonding, such as dirt, oil stains, lubricating oil and rust), and then press the bonding place by hand after bonding until it is preliminarily positioned.

Q:

What's the difference between quick drying glue and AB glue?

A:

Quick drying adhesive - liquid type: slightly lower viscosity, suitable for surface bonding with plane or small gap. It is recommended to use below 3cm.

AB glue gel type: high viscosity, suitable for bonding on uneven surfaces, large gaps and vertical surfaces. The curing time is slow and it is convenient to adjust the bonding position (it is recommended to use more than 3cm).

Q: Which material surfaces cannot be bonded?

A: Polyethylene (PE), polypropylene (PP), PA and POM plastics are difficult to stick, such as automobile plastics, automobile bumpers, plastic containers and plastic hooks. They may fall off after a certain time. If you are not sure about the material, you can consult online customer service. If you need to bond this kind of material, you can buy our fast drying adhesive 180 primer.

Q: How to deal with sticking to your fingers?

A: If your fingers accidentally stick to the quick drying glue, please keep calm and do not tear it forcibly to avoid skin injury. Please put your fingers into warm water at about 40 ℃ and rub them open slowly. In addition, if not handled in time, it will fall off naturally after 2-3 days through sweat and metabolism. Magic drop quick drying glue does not contain organic solvent, which meets the standard. Please rest assured to use it.

Q: Can glue and paint be bonded? A smooth surface?

A: The paint surface can be bonded, which may corrode the paint, and the strength is not high. It is not recommended to bond the paint surface. The smooth surface can be bonded. It is recommended to polish it with sandpaper before bonding, and the effect will be better.

Q: Can glue be waterproof or soaked?

A: It only supports daily waterproof, and long-term immersion is not recommended (except 3020 sealant, 7820 nail free glue and shoe repair glue)

Q: How long is the shelf life? How to save?

A: How to save: after use, please wipe the adhesive left in the nozzle with thick paper or cloth, cover tightly and store in a cool place. The storage time of refrigerator fresh-keeping layer can be extended (3-6 months at - 23 ℃ - 2 ℃; 6-12 months at 2-8 ℃)

Do not wipe with the thin cloth of the paper towel box to prevent skin burns caused by heating. When taking out the glue from the refrigerator, please restore the adhesive to normal temperature before use.

Hot Searches