- Product Details

- {{item.text}}

Quick Details

-

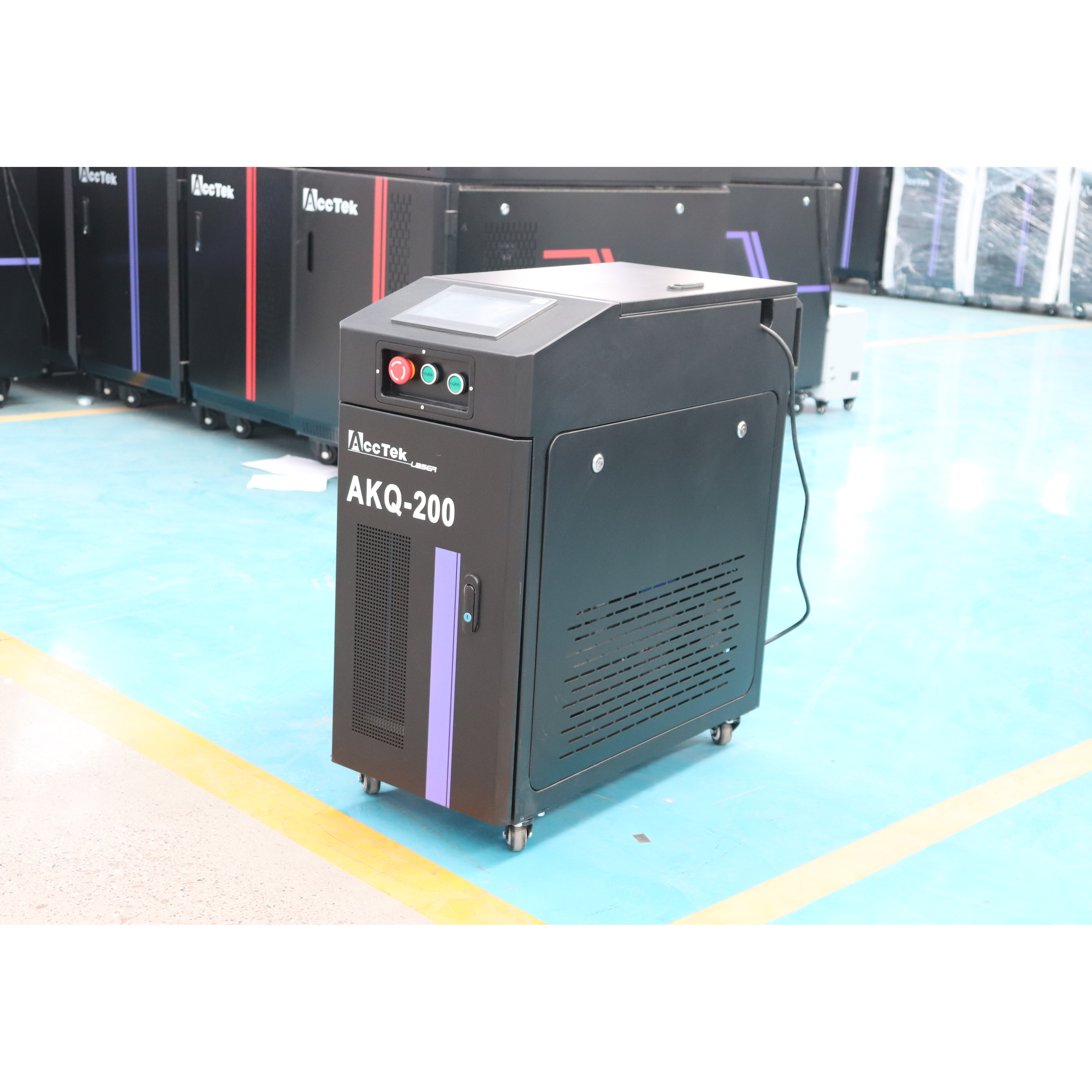

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Single Pulse Energy:

-

120J

-

Pulse Width:

-

0.1-20MS

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

0.3-3mm, 0.1-20ms fiber optic

-

Dimensions:

-

780*485*880mm

-

Weight (KG):

-

102 KG

-

Laser power:

-

100w/200w/300w/500w/1000w

-

Fiber length:

-

3m/5m/8m according to laser power

-

Way of working:

-

Pulse laser/Mopa laser

-

Cooling method:

-

Air cooling/water cooling

-

Working temperature:

-

15-35℃

-

Working humidity:

-

<70% no condensation

-

Certification:

-

ce

-

Cleaning head:

-

AccTek customized

-

Control system:

-

AccTek customized

-

Central wavelength:

-

1064nm

Quick Details

-

Max. Output Power:

-

100-500w

-

Usage:

-

cleaning rust /oil stains/paints etc.

-

Laser Source Brand:

-

JPT/MAX

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Single Pulse Energy:

-

120J

-

Pulse Width:

-

0.1-20MS

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

0.3-3mm, 0.1-20ms fiber optic

-

Dimensions:

-

780*485*880mm

-

Weight (KG):

-

102 KG

-

Laser power:

-

100w/200w/300w/500w/1000w

-

Fiber length:

-

3m/5m/8m according to laser power

-

Way of working:

-

Pulse laser/Mopa laser

-

Cooling method:

-

Air cooling/water cooling

-

Working temperature:

-

15-35℃

-

Working humidity:

-

<70% no condensation

-

Certification:

-

ce

-

Cleaning head:

-

AccTek customized

-

Control system:

-

AccTek customized

-

Central wavelength:

-

1064nm

We are factory!!!

+ High automation,

+ high precision,

+energy saving,

+ After-sale department support!!!

Machine Features

1.

Laser cleaning is a “green” cleaning method that does not need to use any chemicals or cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and can easily solve the Environmental Pollution problems caused by chemical cleaning;

2. The traditional cleaning method is often contact cleaning. The surface of the object to be cleaned has mechanical force, and the surface of the object that will be damaged or the cleaning medium adheres to the surface of the object to be cleaned and cannot be removed, causing secondary pollution. The non-abrasive and non-contact laser cleaning solves these problems;

3. Laser cleaning can be transmitted through optical fiber, cooperate with robots to realize long-distance operation, and can clean parts that are difficult to reach by traditional methods;

4. Laser cleaning can remove all kinds of pollutants on the surface of various materials, and achieve cleanliness that cannot be achieved by conventional cleaning. In addition, it can selectively clean the contaminants on the surface of the material without damaging the surface of the material;

5. High efficiency of laser cleaning, saving time and effort;

2. The traditional cleaning method is often contact cleaning. The surface of the object to be cleaned has mechanical force, and the surface of the object that will be damaged or the cleaning medium adheres to the surface of the object to be cleaned and cannot be removed, causing secondary pollution. The non-abrasive and non-contact laser cleaning solves these problems;

3. Laser cleaning can be transmitted through optical fiber, cooperate with robots to realize long-distance operation, and can clean parts that are difficult to reach by traditional methods;

4. Laser cleaning can remove all kinds of pollutants on the surface of various materials, and achieve cleanliness that cannot be achieved by conventional cleaning. In addition, it can selectively clean the contaminants on the surface of the material without damaging the surface of the material;

5. High efficiency of laser cleaning, saving time and effort;

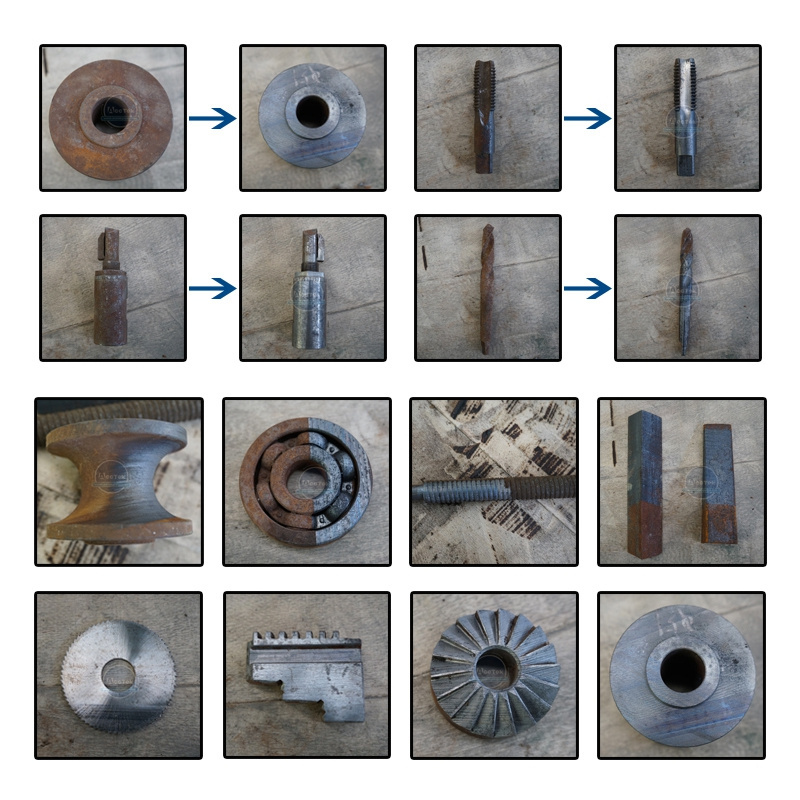

Working Samples

>> Materials:

The portable pulse laser cleaning machine has a good cleaning effect on iron, carbon steel plate, stainless steel plate, mold steel gear, aluminum plate, paint layer, and other materials.

>>Type:

It can be used to clean the oxide layer, surface paint removal treatment, clean surface oil, stains, and dirt, clean rubber mold residues

>>Industry:

and meet the equipment cleaning requirements in the fields of the shipbuilding industry, auto parts, rubber molds, machine tools, and environmental protection industries.

Product Paramenters

|

NO

|

Description

|

Parameter

|

|

1

|

Model

|

AKQ-100/AKQ-200/AKQ-300/AKQ-500

|

|

2

|

Laser Power

|

100W / 200W/300W/500W

|

|

3

|

Range of adjustable power

|

1-100%

|

|

4

|

Central wavelength

|

1064nm

|

|

5

|

Line length

|

3M/5M/8M according to the laser power

|

|

6

|

Way of working

|

Mopa/Pulse laser

|

|

7

|

Speed range

|

0-120mm/s

|

|

8

|

Repeat precision

|

±0.01mm

|

|

9

|

Scanning width

|

different according to different feild lens

|

|

10

|

Cooling method

|

water cooling/air cooling

|

|

11

|

Laser Type

|

JPT / MAX

|

|

12

|

Working humidity

|

<70% no condensation

|

|

13

|

Focal Spot Diameter

|

0.2-2mm

|

|

14

|

Packaging type

|

standard wooden case

|

|

15

|

Pulse Frequency

|

0.1-100Hz

|

|

16

|

Voltage

|

220V/380V

|

Details Shows

Service & Feedbacks

1) Guarantee 3 years guarantee of the whole machine. 2 years for laser generator

2) Software issue Our technician is able to re-install or set up by remote

for free.

for free.

3) Hardware issue Main parts(excluding the consumables) shall be replaced/repaired free of charge, if there is any

problem during the warranty period.

problem during the warranty period.

4) Support online Our technician is able to teach you online to run the machine or eliminate

the fault for free.

the fault for free.

5) Training in AccTek factory We are able to train your staff after placed order in our factory for free.

6)On-site training (Recommended, the most effective way) We are able to send technician to your workshop to do the installation and

training. You will need bear the related costs(flight, visa, hotel, training costs, etc.)

training. You will need bear the related costs(flight, visa, hotel, training costs, etc.)

Our Customers

99% of our customers are satisfied with our machine. We have won a lot of positive feedback due to the high quality and reliable service~

Company and Factory Show

Why choose Acctek?

Factory Presets Ensure Optimal Welding

Simple preset selection ensures consistently high-quality laser welding results.

Presets include wobble welding to accommodate wider seams and poorly assembled parts.

Operators can instantly switch between different presets to easily handle multiple material thickness combinations.

Advanced operators can make custom presets, and save for future use, and novice operators can use them to produce the same results.

Novice operators require less training to get started, reducing labor costs while maintaining weld quality, increasing productivity, and reducing scrap.

Quick And Easy To Set Up

The machine is ergonomic, compact, and proven to be the most comfortable and easy-to-use laser gun, with built-in swing welding.

2-step trigger and part contact sensor increase operator safety.

A single cable from the unit carries the laser power, gas, and control connections to the laser gun.

It can quickly switch from standard laser welding to wire welding, and the operation is simple and fast.

Quick And Easy Setup

A clear logo on the rear of the machine makes connection easy and fast.

Simply plug in the power cord and gas connections, attach the clips to the work surface, and you're ready to start your welding operation.

Laser, gas, and laser gun are transmitted through a single cable.

The ethernet computer connection provides access to advanced parameter settings for fine-tuning and saving welding process parameters.

Operator Safety Features

Key switch control to protect the system from unauthorized welding operations.

The emergency stop button can ensure that the machine can be shut down immediately when there is a problem.

Safety interlocks verify the integrity of laser delivery to the welding gun.

Laser triggering requires 2 steps (1: Laser Ready; 2: Laser Emission) to ensure safe welding operations.

If the welding gun is not in contact with the part being welded, the part contact electrical interlock will turn off the laser power.

If anyone other than the operator accidentally enters the welding area, the door-opening interlock circuit turns off the laser.

Get Laser Solutions

We can customize the design according to your requirements. You only need to tell us your requirements, and our engineers will provide you with turnkey solutions in the shortest possible time. Our laser equipment prices are very competitive, please contact us for a free quote. If you need other laser equipment-related services, you can also contact us.

FAQ

1, How long is the delivery time of this laser machine?

For standard machines, it would be 7-14 working days;

For non-standard machine and customized machines

according to client s specific requirements

2, Do you arrange shipment for this laser 3-in-1 machine from china?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you.

For EXW price, clients need to arrange shipment by themselves or their agents.

3, Do you provide trade assurance for this laser 3-in-1 machine?

--We are member of trade assurance.

You will get

• Order quality and on-time shipment safeguards

• 100% payment refund up to Trade Assurance Amount

4, I did not imported before, how should I do?

You only need pay to us, we will arrange all the things to you and teach you how to do. we will

prepare all the documents for you, you don't need worry, because we know what you need.

5, How about the documents after shipment?

We'll send all original documents to you by DHL, for example: the Packing List, Commercial

Invoice, B/L, and other certificates as required by clients.

6, How about the packing?

Free fumigation wooden box

7, MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell

us your port name.

There will be best shipping freight and machine price send to you.

8, If some problems happened to this cnc router china during warranty period, what should I do?

We will supply free parts in machine warranty period if machine have some problem.

While we also supply free after service forever, so any doubts, just let us know, we will give

you solutions in 24 hours.

For standard machines, it would be 7-14 working days;

For non-standard machine and customized machines

according to client s specific requirements

2, Do you arrange shipment for this laser 3-in-1 machine from china?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you.

For EXW price, clients need to arrange shipment by themselves or their agents.

3, Do you provide trade assurance for this laser 3-in-1 machine?

--We are member of trade assurance.

You will get

• Order quality and on-time shipment safeguards

• 100% payment refund up to Trade Assurance Amount

4, I did not imported before, how should I do?

You only need pay to us, we will arrange all the things to you and teach you how to do. we will

prepare all the documents for you, you don't need worry, because we know what you need.

5, How about the documents after shipment?

We'll send all original documents to you by DHL, for example: the Packing List, Commercial

Invoice, B/L, and other certificates as required by clients.

6, How about the packing?

Free fumigation wooden box

7, MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell

us your port name.

There will be best shipping freight and machine price send to you.

8, If some problems happened to this cnc router china during warranty period, what should I do?

We will supply free parts in machine warranty period if machine have some problem.

While we also supply free after service forever, so any doubts, just let us know, we will give

you solutions in 24 hours.

Hot Searches